Materialise Magics

Support Generation

Optimizing support structures for polymer and metal 3D printing is key to preventing deformation and ensuring a successful build. Insufficient support or incorrectly placed structures may cause the build to crash, while excessive support can lead to more waste. Our support generation solutions can help you find the right balance.

Benefits

Optimized workflows

Get the workflow you need using various support modules. Our Magics support generation modules give you flexibility and full control over your supports, while our e-Stage solutions focus on automating support generation for your build.

Reduce cost

Avoid build failures by finding the right balance between printing and minimizing post-processing needs. Decrease your material usage by reducing trapped powder or resin.

Better part quality

Boost the quality of your parts with easily removable supports and a lower risk of build failures.

Time savings

Gain efficiency during data preparation and post-processing thanks to automation and optimized support structures.

Ideal for the 3D printing technology you use

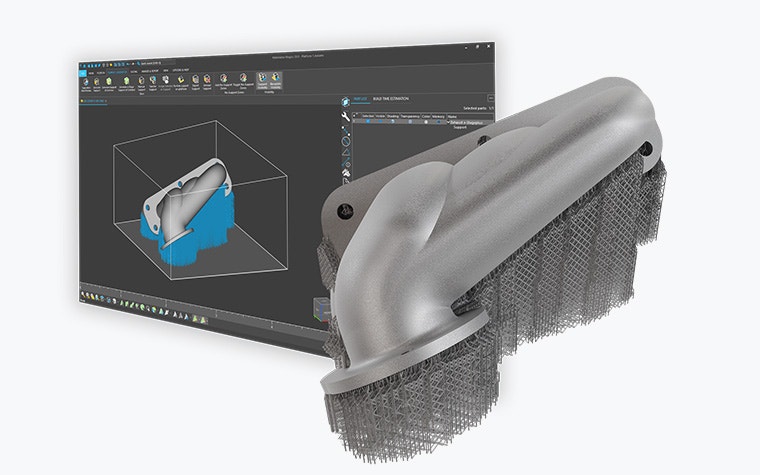

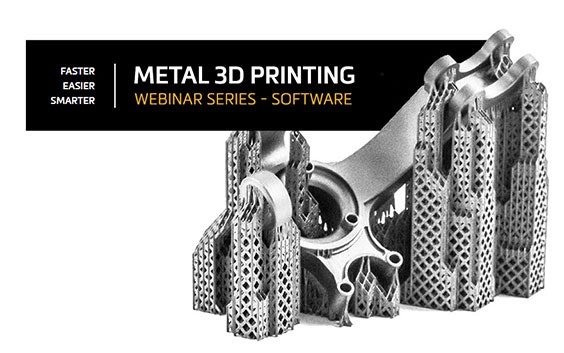

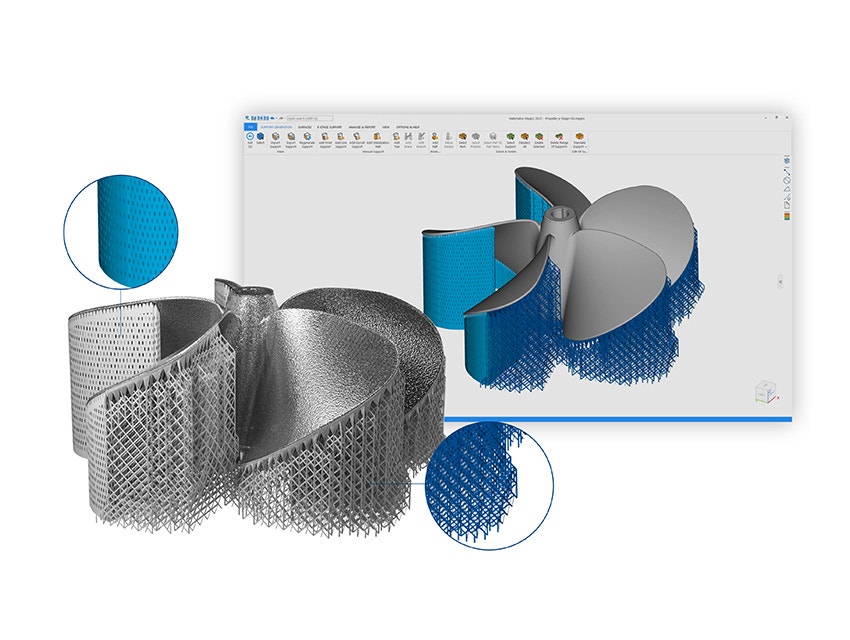

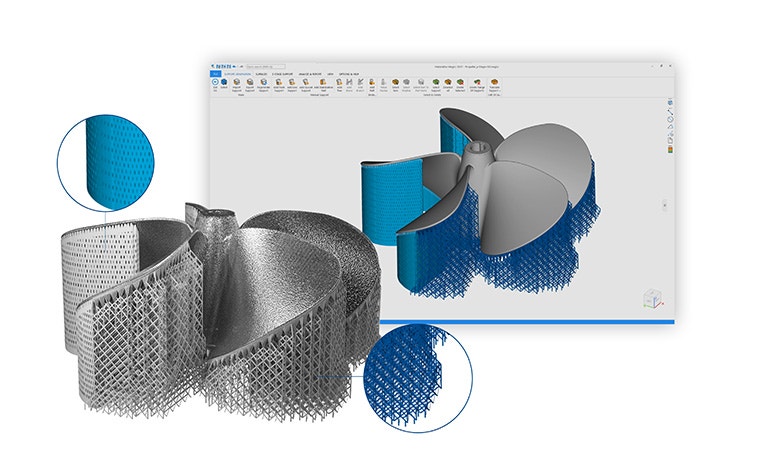

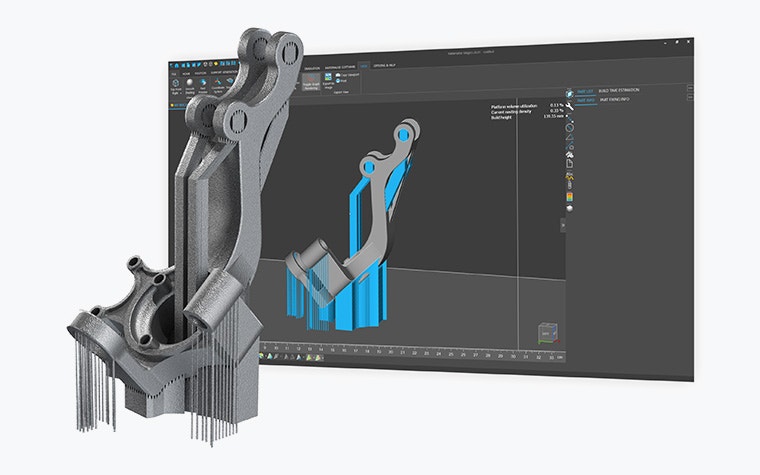

Metal laser powder bed fusion (LPBF)

Deformation, cracking, and dross formation can be avoided with the right support. The SG+ module provides basic automation, allowing you to easily generate adaptable support structures. Meanwhile, e-Stage for Metal+ provides fully automated support to facilitate first-time-right prints. It also uses open grid structures, speeding up excess powder removal while its thin contact points simplify post-processing.

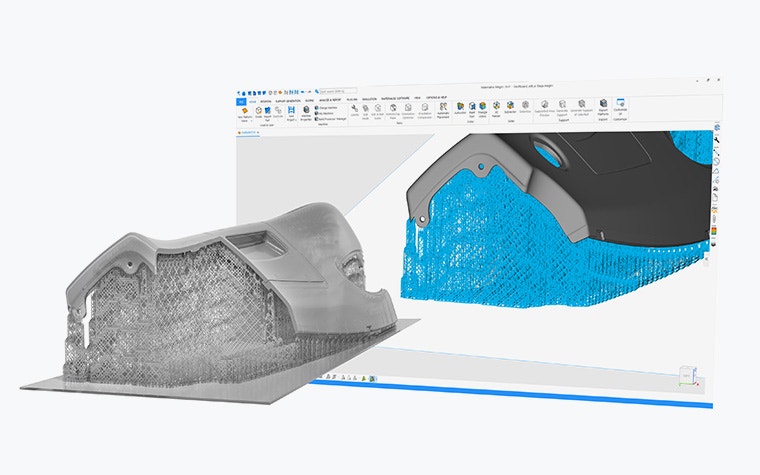

Stereolithography (SLA) and digital light processing (DLP)

Support structures keep your layers from sinking or floating away, countering recoater forces and avoiding shrinkage. The SG module generates support to improve flexibility and printability. e-Stage focuses on automation, where an optimized parameter set controls the support generation, mitigating human errors and ensuring repeatability.

Electron beam melting (EBM)

Support structures help dispense electron buildup in your parts during the printing process. Our SG module provides easy-to-generate support that's suited for the EBM process.

Metal binder jetting

Volume supports provide the stability the parts need to avoid deformation while in the furnace and can prevent the part from sinking during the printing process.

A module to suit every need

SG

Leverage an extensive toolbox for SLA, DLP, and EBM machines with the SG module. Highly customizable, non-solid support structures allow you to reinforce your parts, reducing build failures and scrap while optimizing the surface and part quality. The flexibility of the SG module enables you to improve part quality, reduce post-processing time, and decrease material consumption.

Volume SG

Utilize the tools you need to support your metal binder jetting parts during sintering and keep them in the right shape. The Volume SG module can also be used in extrusion printing, where the volume supports can be hatched correctly during slicing.

SG+

Capitalize on a comprehensive toolbox to maximize the productivity of your LPBF machine with the SG+ module. Combining customizable non-solid and solid structures allows you to optimize support and heat transfer while avoiding breakage or warpage. This minimizes build failures and ensures excellent part quality. Perforations in the support also allow for better powder recuperation.

Learn about support generation

Discover how to get started via our Academy, and get answers to all your questions from customer support.

Inspiration

You might also like

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Nest parts quickly and efficiently to maximize build capacity, protect small pieces, and reduce human error.

Identify error-prone areas of your build before printing so you can get it right the first time, every time.