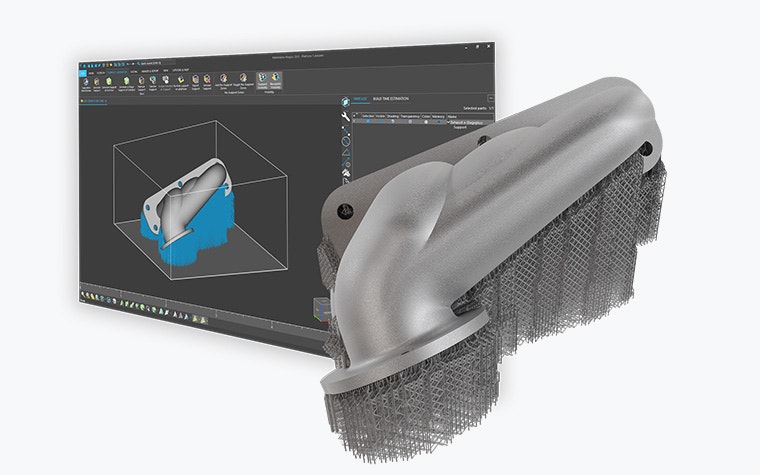

Materialise e-Stage for Metal+

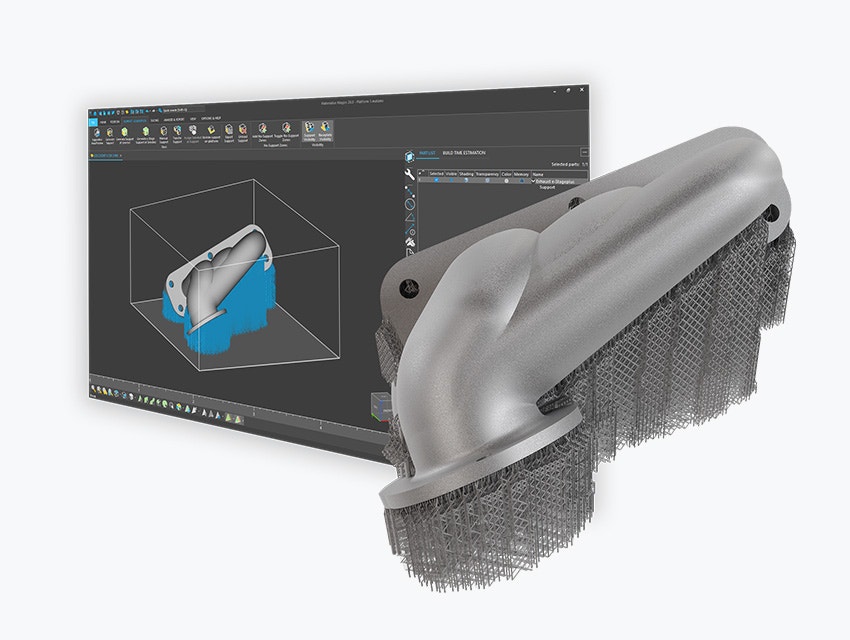

To succeed in laser powder bed fusion (LPBF) metal 3D printing, you must ensure your operations are economically viable. That means keeping costs low, part quality and consistency high, and getting prints right the first time. With e-Stage for Metal+, you can fully automate support generation to achieve these goals during every stage — from data preparation to post-processing.

Benefits

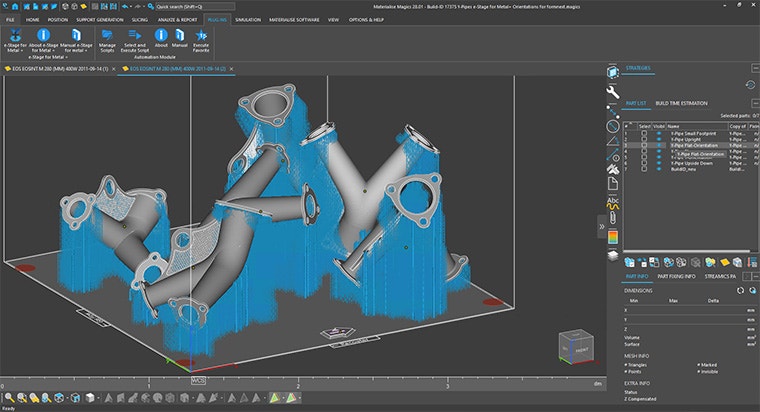

Streamline data preparation

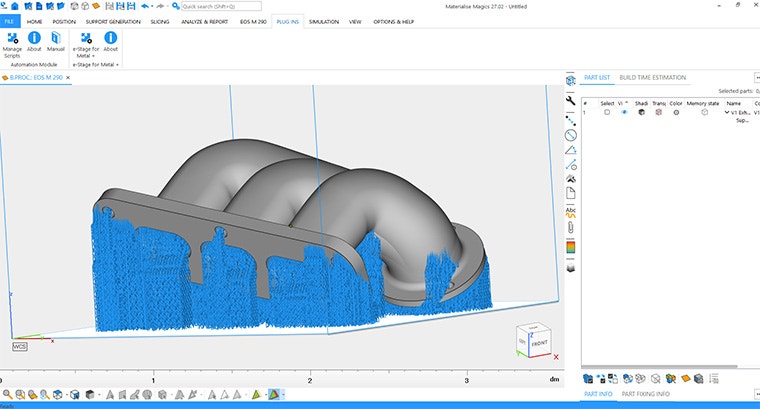

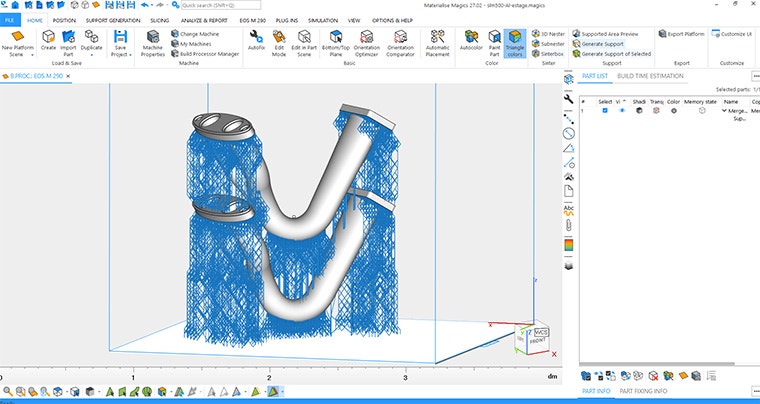

Reduce your time spent on support design by up to 90% while minimizing human error and build crash risk. e-Stage for Metal+ automates support generation to ensure proper stabilization and prevent deformations in your build.

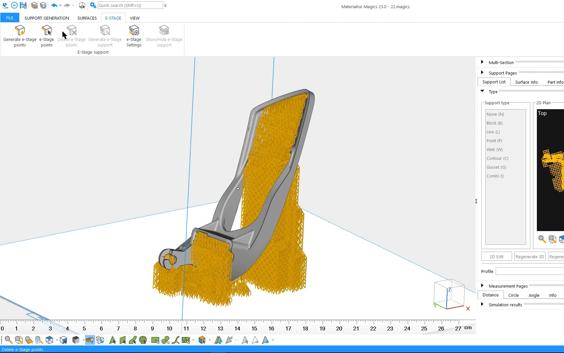

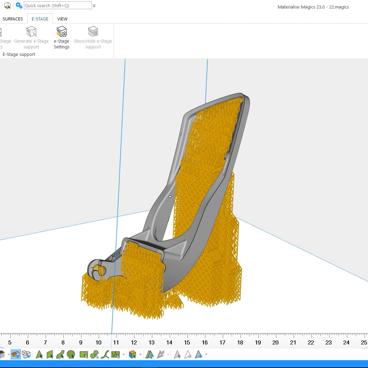

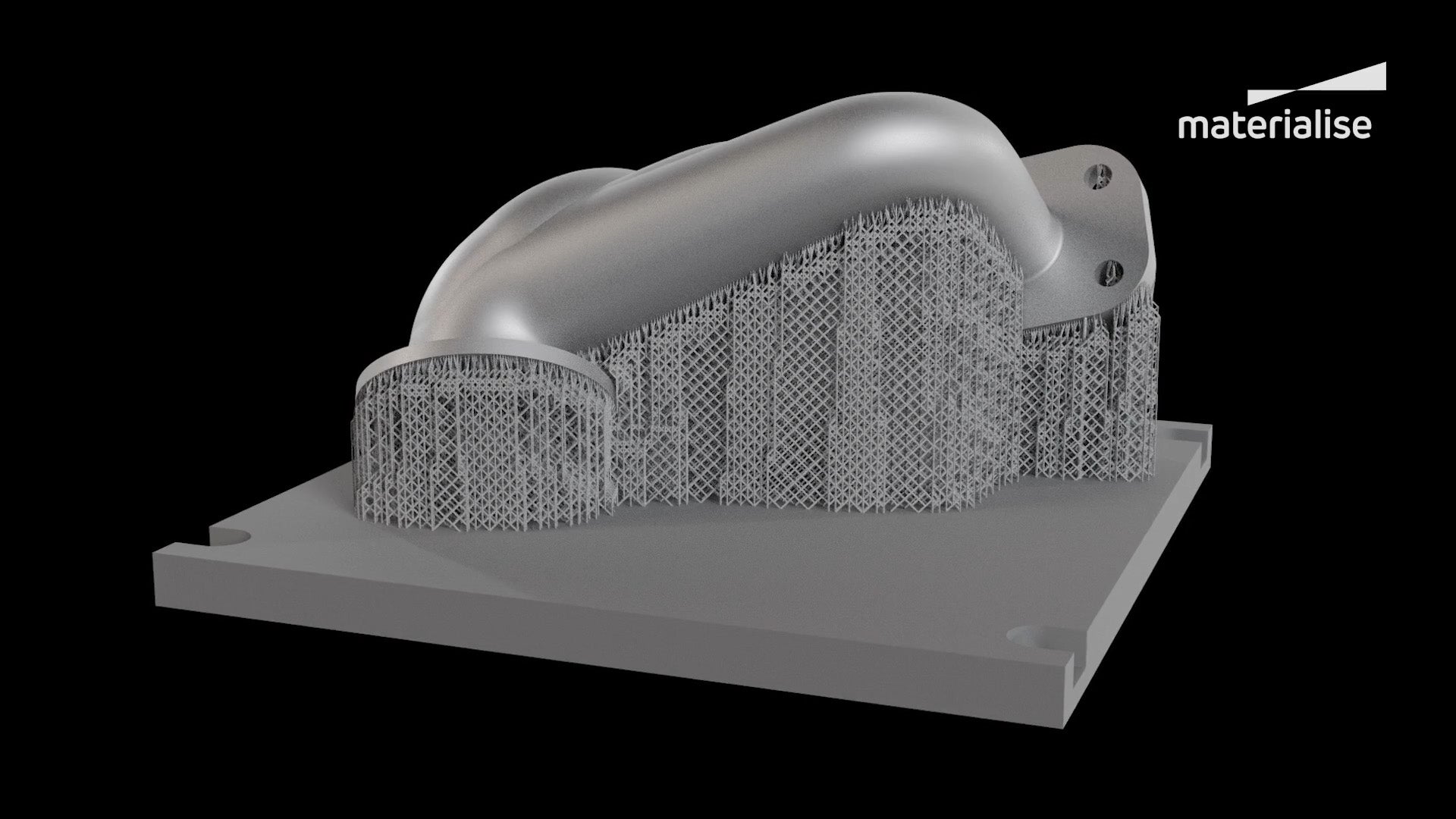

Reduce time spent removing supports

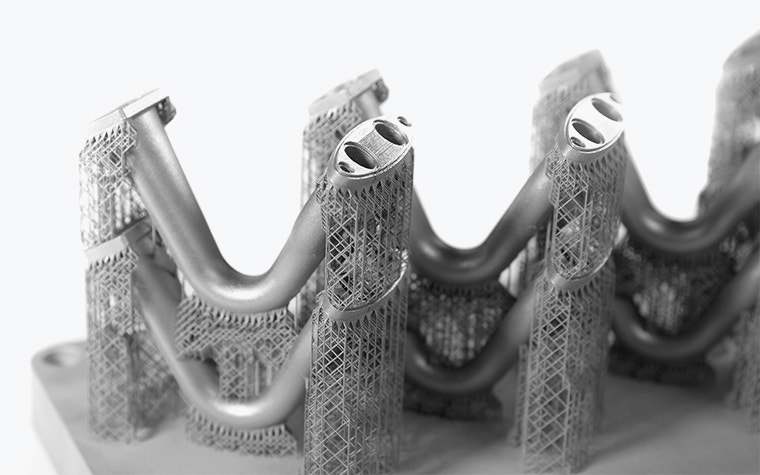

With easy-to-remove, needle-thin contact points and a flexible grid structure, you'll remove almost 100% of the excess powder from the support structure and lower risks related to your operators’ health and security (HSE).

Simplify post-processing

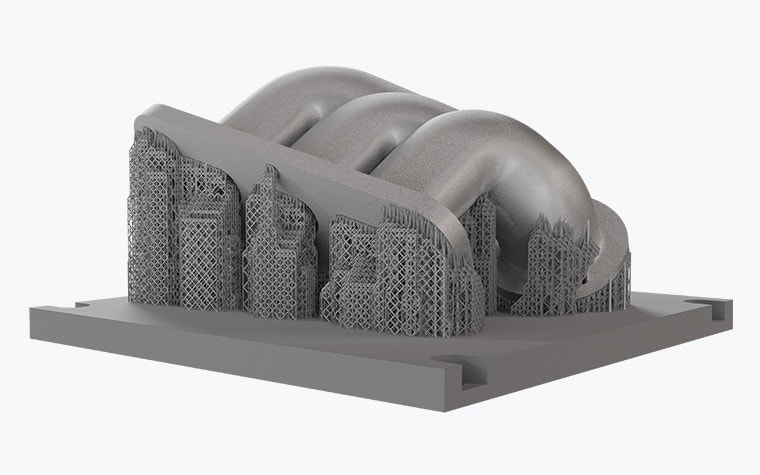

Generate only the support structures you truly need to significantly reduce post-processing time compared to traditional support generation techniques.

Minimal structures, maximum support

You can ensure a successful build without adding tons of extra support. e-Stage for Metal+ determines exactly where support is needed so you print first time right without wasting material or time removing unnecessary structures.

Features

Learn about e-Stage for Metal+

Discover how to get started via our Academy, and get the answers to all your questions from customer support.

Inspiration

You might also like

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Build confidence in your 3D-printed end-use parts by demonstrating process stability in R&D, validation, production, and root cause analysis with AI and IIoT.

Identify error-prone areas of your build before printing so you can get it right the first time, every time.