Benefits

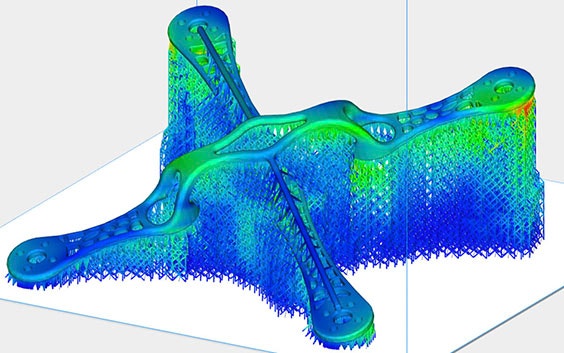

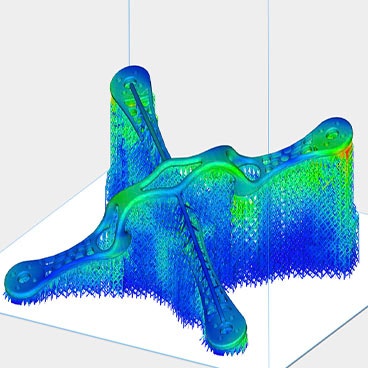

Minimize time-to-market and development costs

Assess part distortion to effectively position and adapt support structures. Minimize expensive test builds, speed up time-to-market, and reduce development costs.

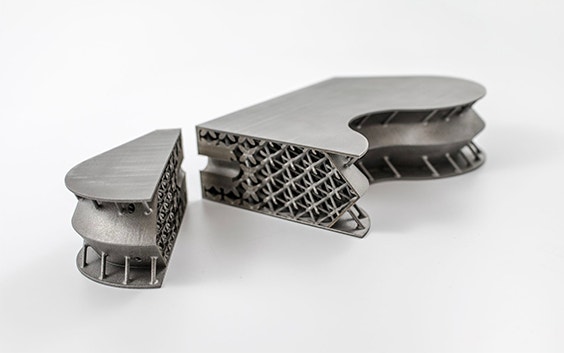

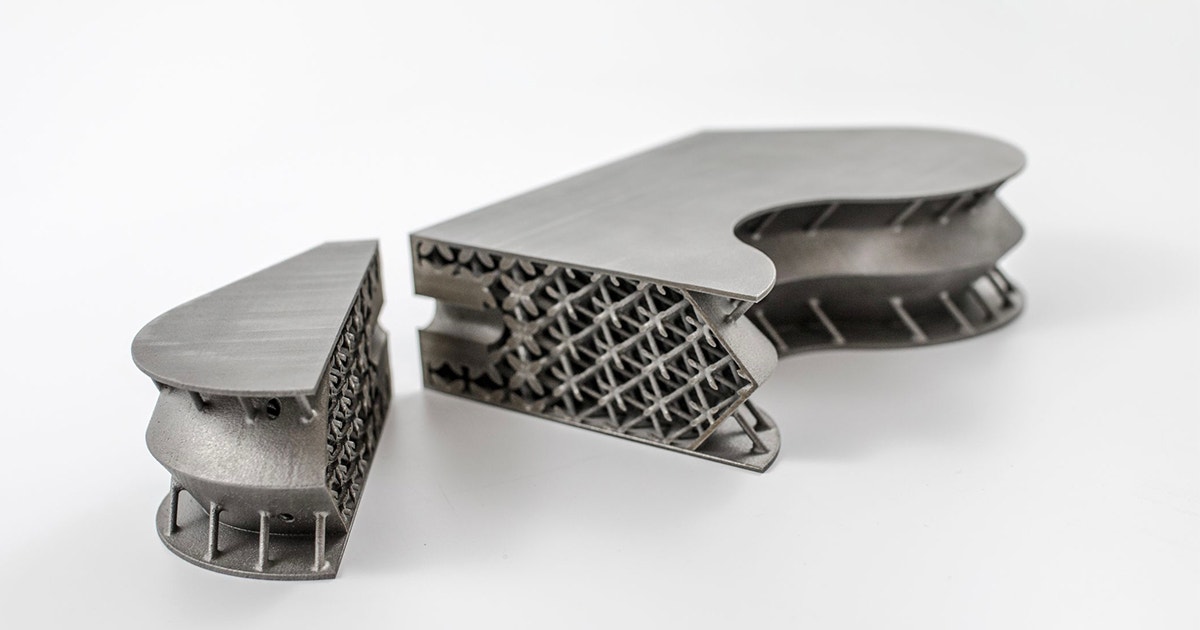

Reduce scrap rate

Predict different build risks of large parts prone to residual stresses and distortion. Identify build failure using robust AM process simulations.

Improve product quality and accuracy

Avoid overheating and achieve better surface quality. Generate compensated part geometry to improve geometrical accuracy.

Validate data preparation

Simulate and assess part orientation for AM processes and add support where needed. Use simulation results to make impactful decisions on the part preparation.

5 reasons to choose the Ansys Simulation module

- The module is for everyone and easy to use, offering a flat learning curve and quickly generating results without the need for expert knowledge

- Prevent operation and transfer errors without switching between software systems

- Evaluate AM-relevant results and optimize your Magics data prep results by seamlessly integrating them into Magics’ workflow

- Leverage market-proven, high-end AM simulation technology powered by the Ansys solver

- Boost AM ROI with a competitively priced software module designed for metal 3D printing

Features

Learn about Simulation

Discover how to get started via our Academy, and get answers to all your questions from customer support.

You might also like

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Optimize and automate support generation with options tailored to different materials, technologies, and geometries.

Nest parts quickly and efficiently to maximize build capacity, protect small pieces, and reduce human error.