CASE STUDY

CO-AM Platform Connects BMI, Toolkit3D, and Extol to Enable Mass-Personalized O&P Medical Products

Connectivity and accuracy are key characteristics for any supply chain to run smoothly, particularly in industries that use patient data and are looking to adopt mass personalization at scale — such as the medical device sector. Digitalizing the supply chain is essential, as business automation simplifies manual, repetitive tasks, eliminates unnecessary communication, and prevents human errors.

Industry

Orthopaedics and prosthetics

Key solutions

Materialise CO-AM Software Platform

The impact

- Streamline communication and manual processes in one secure platform

- Provide a digital thread for the supply chain

- Easy to use and integrate different APIs into the CO-AM platform

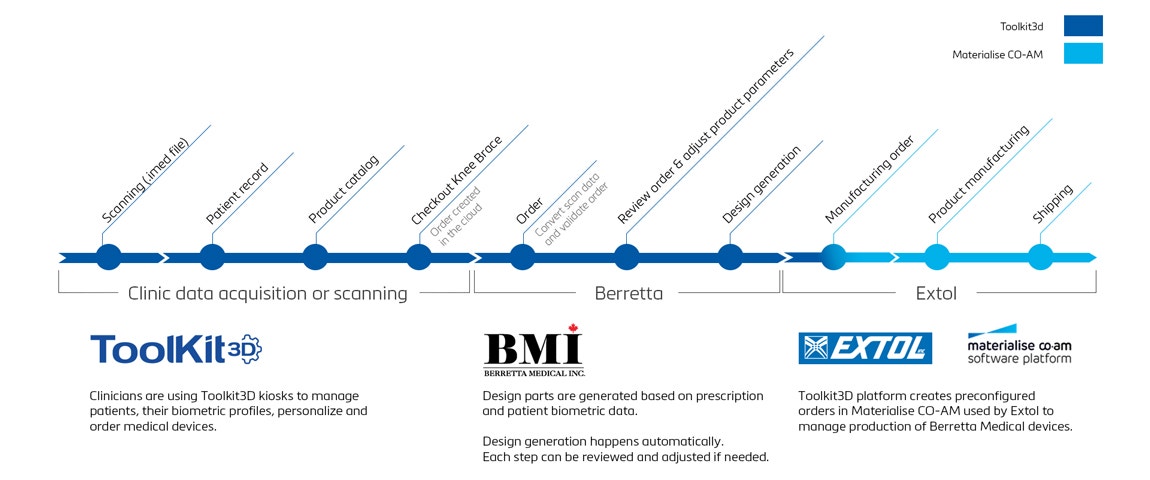

Materialise CO-AM seamlessly connects different parties in the supply chain together in one secure, unified platform. Take BMI, Toolkit3D, and Extol, for example. CO-AM helped them save time and resources — forming a digitally connected thread — to produce custom 3D-printed knee braces.

1) Scanning patient data and designing 3D-printed braces

BMI adopts 3D modeling with the help of Toolkit3D

Berretta Medical Inc. is a family-owned business that manufactures and distributes products for the orthopaedic and prosthetics (O&P) industry. One of BMI’s main products is bespoke braces, traditionally manufactured using milling and molding. However, creating these braces takes time due to the complexity and craftmanship involved. And other macro factors, such as COVID-19, labor shortages, and increasing costs, redirected the company’s focus — leading them to explore 3D printing.

“We're a small team of around five people and produce around 2,000 braces a year. It can take one person a whole day to create a brace because of the molding process. So, we decided to use 3D printing and digitization to accelerate our production and solve these challenges. Plus, it's a lot easier to manage and control," says Nick Berretta, Business Development Lead and Owner of BMI.

A 3D-printed bespoke brace and a scan processing to part fitting workflow. Credit: Berretta Medical Inc., and Toolkit3D.

As BMI was new to the 3D printing world, they contacted Toolkit3D, an online software platform specializing in 3D modeling and customization, to help them. “After scanning the patient, BMI’s skilled technicians needed to mold the brace into physical pieces from scratch with the help of a positive of the patient’s leg. With our design engine, BMI could now easily generate and customize their designs in 3D,” says Sean-Philippe Viens, Lead Mechanical Specialist at Toolkit3D.

Using Toolkit3D's design engine (Shapeshift 3D) enabled BMI to adopt a more straightforward, flexible design approach. However, BMI still had four different processes to navigate before the braces could be shipped: scanning the patient, inputting the patient’s records and product parameters into the system, generating a design, and manufacturing the customized brace with HP MJF printers. Although these steps are digitized and have some level of automation, each workflow is also siloed. This adds complexity and more chances of human error to their production workflow.

“We’re still quite new to the world of 3D printing, but we knew that additive manufacturing (AM) and digital workflows would be ideal for us, practically and economically. We needed a solution that minimized risks, saved us time during the design and admin stages, and was easy for our employees to use. That’s why we chose Toolkit3D; it does all this and connects us to our supplier via the CO-AM platform. Now, we only need to use one solution, simplifying things for us and providing cost benefits,” says Nick.

2) Connecting the design with the supplier in one secure platform

Toolkit3D's API seamlessly interfaces with the CO-AM platform used by Extol

This collaboration was the first time BMI and Toolkit3D had worked together; however, Toolkit3D has experience working with other businesses unfamiliar with 3D printing.

“The level of 3D printing knowledge in the O&P industry is low. Most companies often have little or no experience. Companies that have briefly tried 3D printing conclude it isn’t viable because they lack key elements that allow them to scale. Our Toolkit API solution connects to CO-AM, the digital supply chain platform used by Extol, BMI’s qualified supplier for their 3D-printed braces. Having one platform linking us all together adds real value,” says Sean-Philippe.

Using a dedicated design engine for the braces and Toolkit3D to handle the backend processes — from analyzing the product catalog and validating the scanned data to processing the order for Extol to manufacture with their HP MJF printers — is a game changer for BMI. “Dealing with only one platform makes life easier for us, saving us between 5 – 10% concerning part costs. And it only takes us 20 – 30 minutes to design our braces now,” says Nick.

Toolkit3D’s API seamlessly interfaces with the CO-AM platform used by Extol. Now, a digital thread connects the three companies and builds on each one's strengths: in Toolkit3D’s case, optimizing their client’s experience using the software and ensuring that designs are transferred to the supplier for production with HP MJF 4200 printers.

“Integration [with CO-AM] was quick; we only spent a few days implementing our API. Our operation management system has evolved, but CO-AM was the missing piece to streamline the integration between Toolkit3D and Extol,” says Sean-Philippe. “CO-AM benefits BMI as they don’t need their own manufacturing execution system (MES), and Extol receives automated and encrypted files that are compliant,” adds Edward Ponomarev, Chief Commercial Officer for Toolkit3D. “Integrating Toolkit3D with CO-AM allows companies like BMI and Extol to save up to 75% of required manual labor for moving files through their workflows.”

3) Processing, producing, and shipping custom braces

Extol leverages CO-AM to streamline requests from Toolkit3D

Extol is an industry-leading contract manufacturer of 3D-printed medical devices and is BMI’s trusted supplier. But the company also has a long-standing relationship with Toolkit3D. “We started working together during the pandemic, 3D printing masks, and the relationship has grown since,” states Kyle Harvey, Business Unit Manager — Additive Manufacturing at Extol. “We have a shared vision with Toolkit3D to create a fully connected digital process in order to scale mass customized devices, and CO-AM is the bridge we needed.”

CO-AM’s API links different systems together in one platform, such as the factory, operating, manufacturing, and fulfillment systems. Such a breakthrough could have wider implications for mass personalization in the medical device market, too. CO-AM’s ability to interface with mass personalized apps from other companies will drive down costs, potentially increasing the adoption rate of customized devices.

“The most impactful way to accelerate the acceptance of mass personalization in the O&P market is to reduce cost. It’s the third leg of the stool, as technical feasibility and user desirability have been proven,” says Kyle. “Business viability is the next challenge. Manually transferring data, entering orders, and tracking thousands of unique files is labor intensive, and doing it at scale is cost prohibitive. CO-AM and its API allow different islands of automation to connect, enabling an end-to-end digital process. And by being able to centralize our HP MJF 4200 printers in one platform, it helps us streamline our production capacity along with other work orders queued for production. That’s an important key to scaling patient-specific medical devices as it’s a simple solution that offers business viability.”

BMI and Extol are early adopters of automation technology that simplifies mass personalization, but as the business viability becomes more apparent, even more companies and industries may embrace this trend. “In effect, any industries that produce one for a few or one for one will benefit from it,” says Edward. This includes applications such as wearables devices, protective equipment, furniture, and sporting goods.

Multiple solutions, one platform

Building a secure, end-to-end digital supply chain with CO-AM

The result is a solution that fulfills the needs of all three companies. BMI can create models quickly, reduce waste material, and minimize the chance of human error while handling thousands of files. Toolkit3D is now an even more attractive option for inexperienced companies looking to implement 3D printing, as it streamlines many siloed processes and connects them to a leading 3D printing supplier. And Extol can develop new business models by partnering with customers to manufacture mass-personalized products at scale.

CO-AM simplifies workflows by unifying different platforms to enable a fully digital supply chain, from scan to print. This benefits the O&P industry that wants to move closer to customized medical devices and the patients that use them.

Share on: