CASE STUDY

Transforming Eyewear and the Eyewear Industry: Yuniku

When 3D printing meets the right application and the right partners, it has the potential to turn around an entire industry. Meet Yuniku, the world’s first 3D-tailored eyewear to introduce vision-centric design — and an open digital platform that allows any eyewear brand to do likewise.

Industry

HOYA

Eyewear

Key solutions

Selective laser sintering

Materialise Control Platform

Luxura

The impact

Personalization

Digitalization

What makes an innovation truly groundbreaking? Sometimes it’s how it revolutionizes a product or turns around a business model. It could transform an operational process or the customer experience. And sometimes, you come across a transformative product that manages to do all four. That’s Yuniku by HOYA, the innovation that’s set to change the eyewear industry, in partnership with Materialise.

When 3D printing meets the right application and the right partners, it has the potential to turn around an entire industry. We know this because Materialise has helped it happen before. When 3D printing met hearing aid manufacturing, the digital manufacturing of in-ear hearing aids went from 20% of the total to nearly 100% in just two years, enabled by custom software designed by Materialise. Now, the eyewear industry is poised on the edge of something equally momentous. A system that can give any eye care professional the ability to offer their customers fully customized frames, manufactured at one of the world’s most sophisticated additive manufacturing factories.

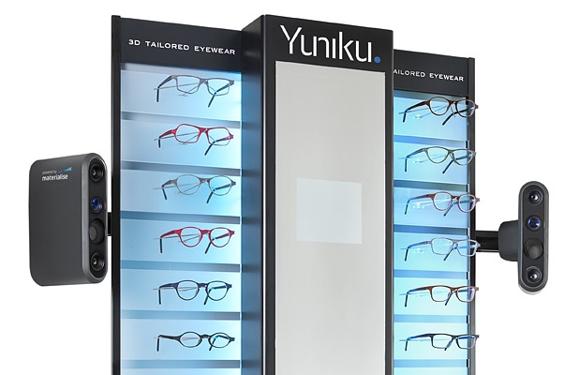

Meet Yuniku, the world’s first 3D-tailored eyewear to introduce vision-centric design — and an open digital platform that allows any eyewear brand to do likewise.

Vision-centric design and why it matters

Conventional eyewear design begins with the frame. Once a customer in an optician’s shop has chosen the frame that they like, the optician selects and places the optical lenses that fit the customer’s visual needs. But placing lenses into a chosen frame can negatively impact lens alignment, resulting in less-than-ideal lens performance. So how do you build eyewear which actually gives the wearer optimal visual experience?

Yuniku uses 3D scanning, parametric design automation, and 3D printing to design the frame of a customer’s choice around the optical lenses chosen by the optician. “Since the position of the lenses is preserved, this concept ensures the ideal orientation of the lenses in your final glasses, in turn ensuring the best visual performance,” says Felix España, Global NewMedia Manager at HOYA Vision Care. Besides, 3D printing allows for complete customization of the frames for the customer’s anatomical features as well as aesthetic preferences.

Hoet Design Studio, the design partner for the base collection of eyewear frames to be used by Yuniku, is already seasoned in 3D-printed eyewear. For Bieke Hoet, Yuniku is an opportunity to take high-performance eyewear from a luxury concept into a normal eye care professional’s reality.

“As an eyewear designer,” Bieke says, “I’m already familiar with how 3D printing can revolutionize this industry. And now with Yuniku, we can share this potential with the world.”

Co-creating a fully digital supply chain

“When we started working with Materialise in 2014 for the HOYA Vision Simulator and EyeGenius, the collaboration led us to start thinking about bigger breakthroughs that our combined knowledge could trigger,” recalls Felix. “What we were looking for was not only a manufacturing partner but an all-round collaborator at every stage.”

To start the co-creation, the Materialise design and engineering services team began adapting their 3D scanning technology to gather a highly-detailed digital 3D scan of customers’ facial features and thereby meet the needs of the HOYA NewMedia team.

Meanwhile, the Materialise R&D team worked with HOYA to develop the Yuniku software. The software allows the eye care professional to take the customer on a journey. After the scan is taken, advanced software designed by HOYA uses facial and visual data to determine the ideal position of the lenses in relation to the eyes and communicates this with Materialise’s software, which in turn tailors the frame around the lenses according to the wearer’s unique facial characteristics.

Frame design, color, and finish can all be adjusted to match the customer’s individual style, guided by the expertise of the eye care professional. The integrated software solutions work in the background to ensure that both ideal lens positioning and fit are preserved. When the perfect 3D-tailored glasses are designed, a back-end ordering system sends HOYA the data required for lens production and the data needed for manufacturing the frames to Materialise.

At Materialise, the frames are manufactured using laser sintering technology dedicated for eyewear, tuned to highly precise parameters using the Materialise Control Platform to access nuanced hardware settings. Finally, the frames undergo the multi-stage post-production treatment of Materialise Luxura. Every frame that comes out of this manufacturing process is entirely unique and authenticated to an individual end-user.

“Materialise innovations have a long track record of developing end-to-end solutions to enhance interaction mechanisms between customers and professionals, enabling novel experiences and innovation in product development,” notes Alireza Parandian, 3D-printed eyewear expert at Materialise. “But HOYA Yuniku goes a step further by introducing an open system that reaches far beyond any single brand.”

A Yuniku experience with an open platform

Although the experience will undoubtedly feel unique for any lifelong glasses-wearer, the Yuniku platform is an open one that can be implemented across any number of stores with any number of brands. Yuniku has been launched with a base collection designed by Hoet Design Studio and will eventually grow to include frames from other designers as well.

For glasses-wearers, Yuniku represents a future where lenses and frames work together rather than compromising each other; where their specific optical needs and aesthetic preferences can be met in a single pair of glasses. For eye care professionals, the Yuniku system empowers them to use their knowledge and take their customers on a novel and exciting journey. But for the eyewear industry and for additive manufacturing, Yuniku is not only design automation but a launchpad of innovation.

Images courtesy of HOYA Vision Care

Share on: