Machinery and Equipment

Optimize industrial production with 3D printing

3D printing brings a competitive edge to every stage of the production line, whether you’re manufacturing the final part or the machine that builds it. Create innovative production tools and prototypes; optimize uptime and make obsolescence obsolete with 3D-printed spare parts that are never out of date; and keep your production running smoothly, with lower costs, flexible operations, and de-risked supply chains.

Why choose 3D printing?

A competitive edge

Product innovation is key to staying ahead of the competition. 3D printing’s flexibility allows you to create new products with complex structures and shapes and capitalize on emerging trends at a moment’s notice.

Operational efficiency

De-risk your supply chain with a digital inventory of 3D-printed parts that you can order and manufacture on demand. Take advantage of short lead times to meet tight deadlines and optimize uptime by redesigning failing parts.

Increase performance, lower costs

Benefit from 3D printing’s unmatched performance-to-cost ratio. No tooling costs or minimum order quantities (MOQ), and the ability to design fit-for-purpose parts without the constraints of traditional manufacturing means you can create parts to do exactly what you need at the right price point.

Why choose Materialise Manufacturing?

Design & Engineering expertise

Create the perfect part from scratch or optimize an existing design for 3D printing by working with our team of engineers specialized in design for additive manufacturing (AM).

The options you need

Printing with Materialise is all about choice. Pick from 3D printing or vacuum casting combined with production-grade metals and polymers to find the ideal solution for even your most demanding projects.

Post-processing included

A diverse range of post-processing options for every material ensures your part is accurate and capable of meeting tight tolerances.

A standardized NPI process

By establishing a clear flow from your concept to your final product, you can guarantee the quality, repeatability, and reliability of every part you print with us.

Ideal materials for machinery and equipment

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

PA-GF

Technology

Selective laser sintering

Description

PA-GF blends polyamide with glass beads to offer higher durability, stiffness, and thermal resistance. It is ideal for prototypes or applications where temperature or wear resistance are key.

Key characteristics

- Strong, stiff material printed without a support structure

- High tensile strength, wear resistance, and temperature resistance (110°C)

- Suitable for post-machining

- Max part dimensions: 630 x 330 x 550 mm

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

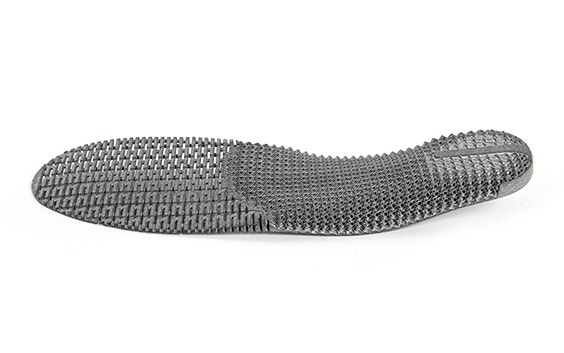

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

Stainless Steel (SS316L)

Technology

Metal 3D printing

Description

Stainless steel (SS316L) is a low-carbon stainless steel alloy that offers excellent strength, high corrosion resistance and ductility, and good thermal properties.

Key characteristics

- Excellent strength

- High corrosion, temperature, and chemical resistance

- High ductility

- Suitable for food-safe applications

- Max part dimensions: 250 x 250 x 305 mm

Aluminum (AlSi₁₀Mg)

Technology

Metal 3D printing

Description

The strength, thermal properties, low weight, and flexible post-processing of this aluminum alloy, AlSi₁₀Mg, make it ideal for manufacturing in industries such as automotive and aerospace.

Key characteristics

- Offers the largest printing volume of all metal 3D printing materials

- Lightweight, with good strength-to-weight ratio

- High thermal and electrical conductivity

- Suitable for post-machining

- Max part dimensions: 500 x 280 x 345 mm

Typical 3D printing applications in machinery and equipment

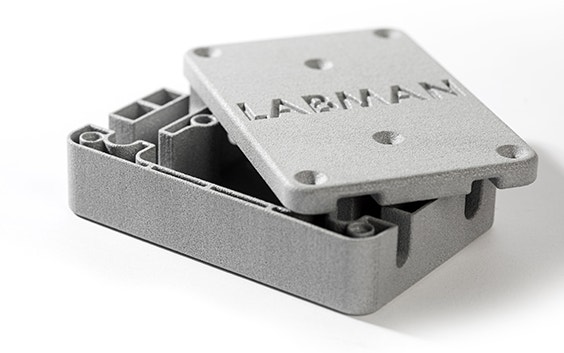

Housings and enclosures

Create unique and customized housings designed fit-for-purpose with production-grade materials. With technologies like 3D printing and vacuum casting, you can adapt designs quickly and easily to keep up with changing requirements and produce the parts you need in short series.

Vibratory bowl feeders

Take automation to another level with the design freedom of 3D printing. Integrate threads into your design, and ensure longevity by using production-grade and reinforced polymers such as PA-GF and PA-AF.

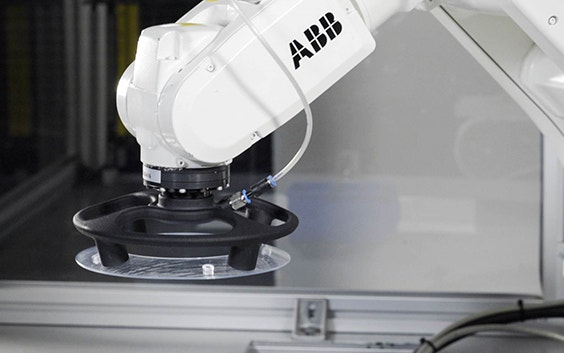

End-of-arm tooling

Build customized lightweight grippers, nozzles, and brackets that improve efficiency and cycle times from metal or polymers, on demand and with no minimum order quantity. Integrate internal channels for superior performance or prioritize mass customization thanks to the design freedom of 3D printing.

Molds and forming tools

Through metal powder bed fusion, you can create custom tools that are stronger, lighter, and produce less waste than those made with traditional techniques such as milling. Take advantage of high-performance metals such as stainless steel and titanium for parts with high corrosion resistance.

Investment casting patterns

Eliminate the need for prior tool production to save both costs and time. Combine the benefits of 3D printing’s design freedom with the performance of cast metal to create the parts you need from a wide range of materials, including transparent options.

Our products and services for machinery and equipment

Ready to start your project with us? Discover our solutions, ideal for your industry.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Inspiration

Get inspired for your next project with a look at how others have used 3D printing for machinery and equipment.

Other industries we work in

Navigate the future of aerospace with shorter lead times, more affordable small series production, and the unrivaled design freedom that additive manufacturing can offer.

From quick, performant prototypes and visual models to small series manufacturing and automotive tooling, tick every box by bringing 3D printing into existing or new production workflows.

Enter a new era of more sustainable, on-demand manufacturing where creativity and innovation have no boundaries and where quick time-to-market, and zero stock-risk, boost business agility.