Materials

Your project, your way. With an incredible range of materials, from performance-grade metals to engineering polymers and cast polyurethanes, you can be sure you’ll find the right fit for your needs at Materialise. Discover the complete collection for different manufacturing technologies right here and create parts with the mechanical properties, functional characteristics, or looks you need for your project.

Metal 3D printing

Aluminum (AlSi₁₀Mg)

Technology

Metal 3D printing

Description

The strength, thermal properties, low weight, and flexible post-processing of this aluminum alloy, AlSi₁₀Mg, make it ideal for manufacturing in industries such as automotive and aerospace.

Key characteristics

- Offers the largest printing volume of all metal 3D printing materials

- Lightweight, with good strength-to-weight ratio

- High thermal and electrical conductivity

- Suitable for post-machining

- Max part dimensions: 500 x 280 x 345 mm

Titanium (Ti₆Al₄V)

Technology

Metal 3D printing

Description

Ti₆Al₄V is a lightweight titanium alloy with excellent mechanical strength and superior corrosion resistance, making it ideal for high-performance end-use parts.

Key characteristics

- Excellent mechanical properties

- Lightweight, with a high strength-to-weight ratio

- High corrosion and temperature resistance

- Suitable for post-machining

- Max part dimensions: 250 x 250 x 305 mm

Stainless Steel (SS316L)

Technology

Metal 3D printing

Description

Stainless steel (SS316L) is a low-carbon stainless steel alloy that offers excellent strength, high corrosion resistance and ductility, and good thermal properties.

Key characteristics

- Excellent strength

- High corrosion, temperature, and chemical resistance

- High ductility

- Suitable for food-safe applications

- Max part dimensions: 250 x 250 x 305 mm

Inconel (IN718)

Technology

Metal 3D printing

Description

Inconel (IN718) is a high-strength, corrosion-resistant alloy with exceptional thermal resistance. Ideal for high-performance parts that need to withstand extreme conditions.

Key characteristics

- Exceptional thermal resistance up to 700°C

- High corrosion resistance

- High yield, tensile, and creep-rupture strength

- Suitable for post-machining

- Max part dimensions: 250 x 250 x 305 mm

Stainless Steel (C465)

Technology

Metal 3D printing

Description

Stainless steel (C465) is an age-hardenable stainless steel alloy that offers excellent strength and fracture toughness, and high corrosion resistance, making it ideal for high-performance end-use parts.

Key characteristics

- Excellent tensile strength, hardness, and fracture toughness

- High corrosion resistance

- Age-hardenable steel alloy

- Max part dimensions: 250 x 250 x 305 mm

Selective laser sintering

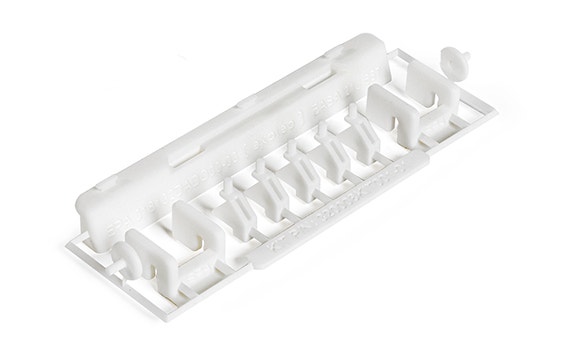

PA 12 Medical-Grade (PA 2201)

Technology

Selective laser sintering

Description

PA 12 Medical-Grade offers high strength, chemical resistance, and detail resolution, making it ideal for high-quality and fully-functional biocompatible plastic parts for settings such as operating rooms. This material is subjected to testing for cytotoxicity, sensitization, irritation, acute systemic toxicity, and material-mediated pyrogenicity.

Key characteristics

- Biocompatible material

- High strength and stiffness

- Good chemical resistance

- High selectivity and detail resolution

- Max part dimensions: 170 x 215 x 320 mm

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

PA-AF (Aluminum Filled)

Technology

Selective laser sintering

Description

PA-AF blends polyamide with aluminum to produce strong, stiff parts resistant to temperatures of up to 130°C. With a metallic appearance, it is ideal for models, rapid tooling, and fixtures.

Key characteristics

- Strong, stiff material printed without a support structure

- Slightly sparkly metallic appearance, suitable for post-machining

- High temperature resistance (130°C)

- Max part dimensions: 630 x 330 x 550 mm

PA-GF

Technology

Selective laser sintering

Description

PA-GF blends polyamide with glass beads to offer higher durability, stiffness, and thermal resistance. It is ideal for prototypes or applications where temperature or wear resistance are key.

Key characteristics

- Strong, stiff material printed without a support structure

- High tensile strength, wear resistance, and temperature resistance (110°C)

- Suitable for post-machining

- Max part dimensions: 630 x 330 x 550 mm

Polypropylene (PP)

Technology

Selective laser sintering

Description

A tough, fatigue-resistant, and lightweight material, polypropylene (PP) is ideal for functional prototypes of snap-fit assemblies or living hinges in automotive components, packaging, and consumer goods.

Key characteristics

- Tough yet flexible material printed without a support structure

- Very high elongation at break (> 500%)

- Lightweight and fatigue resistant

- Max part dimensions: 480 x 480 x 430 mm

PA 2210 FR

Technology

Selective laser sintering

Description

PA 2210 FR is a high-performance, UL Blue Card-certified polyamide containing a halogen-free flame retardant. Excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — UL Blue Card-certified (UL 94 rating of V-0 at 3 mm wall thickness), CS/FAR 25.853 compliant

- High chemical, mechanical, and thermal resistance

- Max part dimensions: 280 x 280 x 550 mm

PA 2241 FR

Technology

Selective laser sintering

Description

PA 2241 FR is a high-performance, flame-retardant polyamide. Its excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — CS/FAR 25.853 compliant, available in Airbus certified grade, according to AIPI 03-07-022

- Excellent long-term stability and high chemical resistance

- Max part dimensions: 630 x 330 x 550 mm

Multi Jet Fusion

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

PA 12S

Technology

Multi Jet Fusion

Description

Combining an excellent level of detail and dimensional accuracy with minimal post-processing, this eye-catching material is ideal for fast iterations during prototyping or low-requirement series production.

Key characteristics

- High visual specifications

- Excellent dimensional accuracy

- Low post-processing requirements

- Max part dimensions: 370 x 274 x 375 mm

PA 11

Technology

Multi Jet Fusion

Description

Combining excellent mechanical properties with impressive surface quality and detail, this material is ideal for both series production and functional prototypes, especially in industries like medtech (O&P), aerospace, and automotive.

Key characteristics

- Flexible and stress-resistant

- Excellent surface detail and dimensional accuracy

- High density and isotropy

- Smooth surface quality with minimal post-processing

- Max part dimensions: 370 x 274 x 375 mm

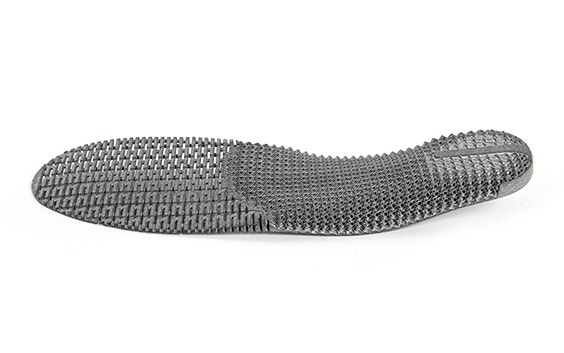

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

Stereolithography

Poly1500

Technology

Stereolithography

Description

Poly1500 is a durable, resilient material that offers high surface quality and dimensional accuracy. With properties similar to polypropylene, it is ideal for functional prototypes.

Key characteristics

- Similar properties to polypropylene

- Good durability, impact resistance, and heat resistance

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

ProtoGen White

Technology

Stereolithography

Description

ProtoGen White's resilience, surface quality, and thermal properties make it suitable for general-purpose prototypes such as highly detailed parts, and durable concept models.

Key characteristics

- Similar properties to ABS

- Resilient material with good surface quality

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

TuskXC2700T

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700T is a strong material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes and high-end finished models. Transparent finishes possible.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Great surface quality, with transparent finishes possible

- Among the largest printing volumes of stereolithography materials

- Fast Lane service available for online orders of TuskXC2700T – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 2,000 x 700 x 788 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

TuskXC2700W

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700W is a strong material with a rapid lead time. It is ideal for water-resistant and functional prototypes. Also available in clear.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Fast Lane service available for online orders of TuskXC2700W – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 350 x 350 x 350 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

Taurus

Technology

Stereolithography

Description

Taurus has the look and feel of an injection-molded part, offering strong mechanical properties and high surface detail. It's an ideal choice for form-, fit-, and function-testing, as well as functional prototypes.

Key characteristics

- Injection-molded look and feel

- Strong mechanical properties

- High surface detailing

- Max part dimensions: 480 x 480 x 560 mm

Xtreme

Technology

Stereolithography

Description

Xtreme is a tough, general-purpose material with high impact strength, high elongation, and excellent surface quality. With properties close to ABS, Xtreme is ideal for functional prototyping.

Key characteristics

- General-purpose material with properties similar to ABS

- High impact strength and elongation at break

- Excellent surface quality

- Max part dimensions: 480 x 480 x 560 mm

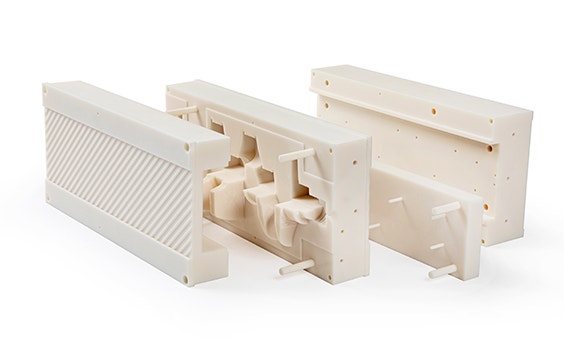

PerFORM

Technology

Stereolithography

Description

A resin with ceramic particles, PerFORM offers high stiffness and strength, as well as excellent heat resistance and detail. It is ideal for prototyping and for rapid tooling for injection molds.

Key characteristics

- Stiffness comparable to glass fiber-reinforced polycarbonate

- High thermal resistance and excellent detail resolution

- Superior sidewall quality

- Max part dimensions: 800 x 800 x 585 mm

VersaClear

Technology

Stereolithography

Description

VersaClear is a robust, translucent, water-resistant resin that combines reliable performance with a clear, professional finish and high detail resolution for intricate and precise designs. It's a cost-effective, versatile all-rounder for prototypes or high-end finished models.

Key characteristics

- Excellent transparency

- Strong and durable

- Detailed resolution

- Ideal for functional and aesthetic prototypes

Fused deposition modeling

ABS-M30

Technology

Fused deposition modeling

Description

Stronger than standard ABS, ABS-M30 is a versatile, production-grade thermoplastic that is lightweight and resilient. This material is ideal for prototypes, tooling, and end-use parts.

Key characteristics

- Stronger than standard ABS

- Smoother parts and finer feature details than standard ABS

- Very high dimensional accuracy

- Fast Lane service available for online orders of ABS-M30 White/Black - Normal finish

- Max part dimensions: 914 x 610 x 914 mm

- Max part dimensions (Fast Lane orders): 250 x 250 x 300 mm

ABS-M30i

Technology

Fused deposition modeling

Description

Similar to ABS-M30 in strength, durability, and feature detail, ABS-M30i is biocompatible, making it ideal for applications in the food packaging, pharmaceutical, and medical device industries.

Key characteristics

- Biocompatible and ISO 10993 compliant

- High tensile, impact and flexural strength

- Very high dimensional accuracy

- Max part dimensions: 914 x 610 x 914 mm

ABS-ESD7

Technology

Fused deposition modeling

Description

ABS-ESD7 combines the strength and durability of ABS with carbon to provide electrostatic dissipative (ESD) properties, making it a safer choice for static-sensitive prototypes and tooling.

Key characteristics

- High impact strength and durability

- Electrostatic-dissipative properties

- Very high dimensional accuracy

- Max part dimensions: 914 x 610 x 914 mm

Polycarbonate

Technology

Fused deposition modeling

Description

Polycarbonate is a Blue Card-certified flame-retardant thermoplastic with excellent impact strength, dimensional stability, and thermal resistance. It is ideal for prototypes, tooling, and end-use parts.

Key characteristics

- Excellent impact strength and temperature resistance

- Flame retardant — Blue Card-certified, UL 94 HB certified

- High flexural and tensile strength, and very high dimensional accuracy

- Max part dimensions: 914 x 610 x 914 mm

PC-ABS

Technology

Fused deposition modeling

Description

PC-ABS combines the strength and heat resistance of polycarbonate with the flexibility of ABS. Offering excellent mechanical properties, it is ideal for prototypes, tooling, and end-use parts.

Key characteristics

- High impact strength and thermal resistance of polycarbonate

- High flexural and tensile strength of ABS

- Very high dimensional accuracy

- Max part dimensions: 914 x 610 x 914 mm

PC-ISO

Technology

Fused deposition modeling

Description

This biocompatible polycarbonate material is known for its high strength and stiffness. Its versatility, durability, and dimensional stability make it ideal for everything from heavy-duty prototypes in industries like aerospace and automotive to small series of end-use medtech parts.

Key characteristics

- High strength and stiffness, ideal for parts exposed to constant stress and heavy loads

- Excellent heat resistance, making it suitable for use in high-temperature environments

- Good chemical resistance and dimensional stability

- Max part dimensions: 914 x 610 x 914 mm

Ultem 9085

Technology

Fused deposition modeling

Description

Ultem 9085 is a flame-retardant thermoplastic. With its superior mechanical performance and strength-to-weight ratio, it is ideal for highly functional prototypes and production-grade end-use parts.

Key characteristics

- Superior mechanical properties, with a high strength-to-weight ratio

- Very high dimensional accuracy

- Max part dimensions: 914 x 610 x 914 mm

PA-CF

Technology

Fused deposition modeling

Description

PA-CF is a strong, stiff, and lightweight thermoplastic filament, reinforced with chopped carbon fiber. Ideal applications include tooling, functional prototypes, and machine parts that undergo regular stress.

Key characteristics

- High strength and stiffness while remaining lightweight

- Highest flexural strength and stiffness-to-weight ratio of any FDM material

- Twice as strong as regular polyamide

- Max part dimensions: 914 x 610 x 914 mm

- Max part dimensions (online orders): 406 x 355 x 406 mm

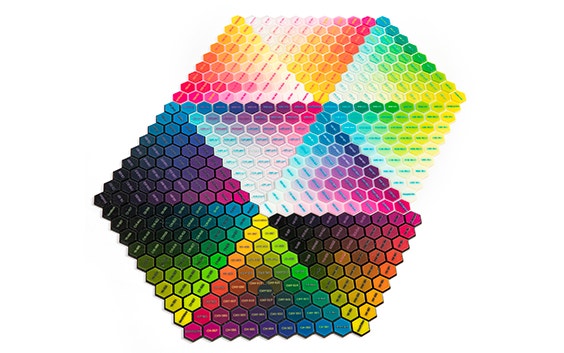

PolyJet

Vero

Technology

PolyJet

Description

Vero is a rigid, opaque material that offers excellent detail and can be blended with other PolyJet materials to determine toughness, rigidity, or translucency. Available in multiple colors.

Key characteristics

- Rigid, general-purpose material

- High level of surface detail

- Can be combined with other PolyJet materials to alter toughness, rigidity, or translucency

- Max part dimensions: 490 x 390 x 200 mm

VeroClear

Technology

PolyJet

Description

VeroClear is a rigid, transparent material that offers high dimensional stability and exceptional surface detail. It is ideal for concept modeling and form- and fit-testing of clear parts.

Key characteristics

- Transparent, rigid material

- High level of surface detail

- Can be combined with colored PolyJet materials

- Max part dimensions: 490 x 390 x 200 mm

Agilus

Technology

PolyJet

Description

Agilus is a flexible, rubber-like resin with superior tear-resistance, elongation, and tensile strength. It is ideal for advanced design verification and prototyping of soft-touch components.

Key characteristics

- Flexible, rubber-like material

- Very high elongation at break

- Good tear resistance

- Max part dimensions: 350 x 250 x 100 mm

Composite Materials

Technology

PolyJet

Description

Flexible, rubber-like Agilus is blended with VeroWhite to offer a range of composite materials with pre-defined Shore values and mechanical properties, providing options for a variety of applications.

Key characteristics

- Pre-defined blends of Agilus and VeroWhite

- The addition of VeroWhite influences Agilus' tensile strength and tear resistance

- Different Shore A hardness values are available

- Max part dimensions: 350 x 250 x 100 mm

Lost-wax casting

Brass

Technology

Lost-wax casting

Description

Brass, an alloy of copper and zinc, is a highly versatile material that offers similar detail to silver and gold. It is ideal for detailed miniatures, sculptures, jewelry or pre-print tests.

Key characteristics

- Affordable substitute for precious metals

- Wide range of platings and colors available

- High surface detailing

- Max part dimensions: 88 x 88 x 125 mm

Bronze

Technology

Lost-wax casting

Description

Bronze, an alloy consisting primarily of copper, is a strong, affordable material with a reddish tint. It is ideal for creating miniatures, antique-looking jewelry, or pre-print tests.

Key characteristics

- Strong, affordable option for metal 3D printing

- Antique look with reddish tint

- High surface detailing

- Max part dimensions: 88 x 88 x 125 mm

Copper

Technology

Lost-wax casting

Description

Known for its reddish color and greenish hue after oxidization, copper is ideal for small, robust and decorative models such as coins, medals, connectors, or statues.

Key characteristics

- High thermal and electrical conductivity

- Reddish color that turns greenish after oxidation

- High surface detailing

- Max part dimensions: 88 x 88 x 125 mm

Gold

Technology

Lost-wax casting

Description

Solid, nickel-free 14K or 18K gold is available in yellow, red, and white gold formulations. Ideal for creating jewelry, finished pieces are hallmarked with a master and purity stamp.

Key characteristics

- 14K and 18K nickel-free gold

- Mixed with alloys to harden the material for longer wear

- High surface detailing

- Max part dimensions: 88 x 88 x 125 mm

Silver

Technology

Lost-wax casting

Description

Malleable and available in five finishes, silver is ideal for jewelry such as rings, cufflinks, bracelets, pendants, and earrings. Finished pieces are hallmarked with a master and purity stamp.

Key characteristics

- 93% sterling silver mixed with alloys to harden the material for longer wear

- High thermal and electrical conductivity

- High surface detailing

- Max part dimensions: 88 x 88 x 125 mm

Vacuum casting

Rubber-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our rubber-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface quality and detail, resembling TPE, TPU, and silicone rubber

- Ideal for applications that need good shock absorption

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

ABS-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our ABS-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Flame-retardant, food-safe, and UV-stable materials available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

PE/PP-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our PE/PP-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Tough and lightweight with a wide range of finishes available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)