CASE STUDY

How CO-AM Offers Scalability and Efficiencies Across the AM Production Process at Extol

Extol is a manufacturing technology company that improves how plastic products are made, with services that cater to customers in various sectors, including automotive, consumer products, and life sciences. With such a diverse clientele, they needed a solution to quickly turn around quotes and track thousands of orders accurately. Extol partnered with our CO-AM Software Platform to scale and improve the company's AM production process.

Industry

Additive manufacturing

Key solutions

CO-AM Software Platform

The impact

Enables scalability: process and track customer quotes and orders accurately

Provides project visibility and streamlines communication

Increases the accuracy of on-time shipments

The challenge

Process and track customer quotes and orders accurately

Extol provides additive manufacturing (AM), plastic assembly technology, and custom automation services to customers, helping them across their 3D printing journeys — from prototyping and development all the way to production. The company prides itself on exemplary collaboration and relishes solving its customers' problems with 3D printing, seamlessly implementing AM solutions for any occasion. Extol's teams have walked the road themselves, and they understand the complex nuances of the technology. In their early years of AM, and as they developed proficiency, various teams relied on traditional workflows and tools to manage projects.

However, as orders grew, they realized that homegrown order tracking spreadsheets were not scalable and that a manufacturing execution system (MES) software would be a smart investment. They needed a solution capable of quickly and accurately delivering quotes while maintaining exceptional levels of customer service. At the same time, this new system must have the ability to track thousands of orders methodically and help support Extol's teams to retain a strong relationship with their customers: a quality that clients have come to expect from the company.

The solution

CO-AM provides an all-in-one solution to scale AM infrastructure

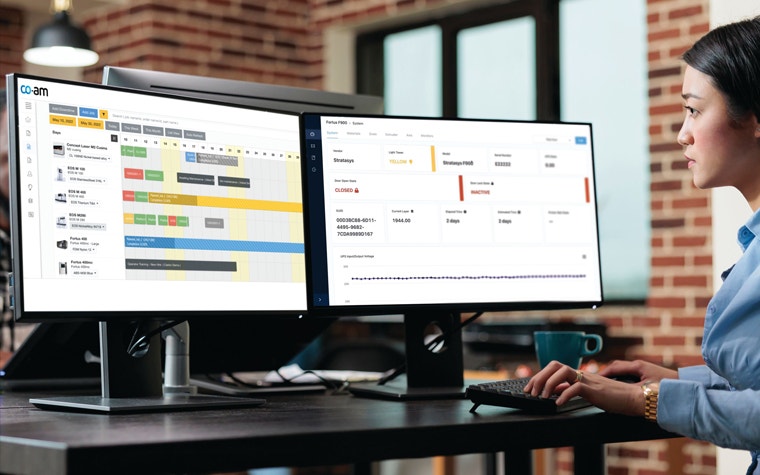

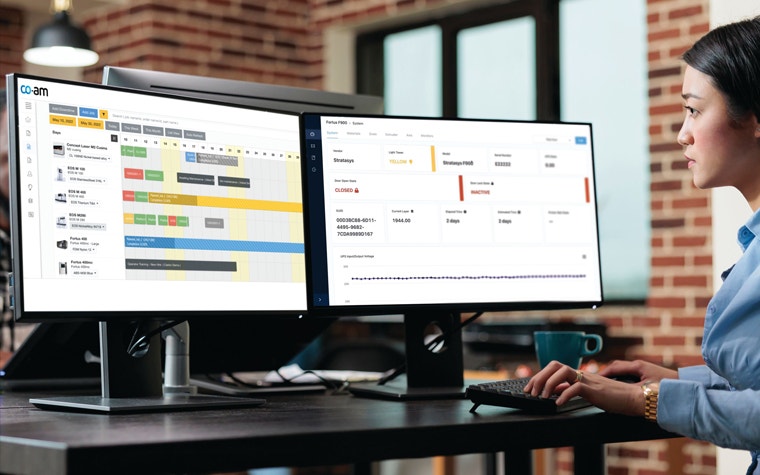

Extol decided to use CO-AM as a one-stop solution to tackle the company's particular challenges. CO-AM’s central data fabric links digital tools and processes feedback across Extol's entire AM workflow. This enabled them to track, control, and continuously improve multiple procedures and effectively scale production across teams and projects.

“It’s safe to say that our AM team lives within CO-AM. Simply put, it’s our production backbone. With CO-AM, we always have a record of what is happening or has happened throughout the complete manufacturing process. It stores all the information we need for every order, from A-Z. The platform allows us to manage thousands of orders seamlessly — something that you simply can’t do manually — while driving down costs and increasing production efficiencies,” says Kyle Harvey, Business Unit Manager for Extol and an AM champion helping to pioneer growth opportunities for the company.

The result

A scalable AM production process with efficiencies across the operational workflow

Extol partnered with CO-AM, and the relationship became an excellent example of a best-in-class collaborative growth story. The partnership started as a solution for helping to quote projects more accurately but soon grew into a system that provided efficiencies across the AM production process.

“Our team is continually impressed with the platform’s ability to bring ideas to the table, implement quick changes for varied production processes, and enable us to drive more efficiencies than we ever thought possible,” states Kyle. "They haven’t just cut our costs, but they’ve also increased our ability to serve our customers.”

CO-AM provided the software solution that enabled scalability for Extol, offering its employees the ability to manage thousands of orders at any given time — vital for order management. As every order resides within CO-AM, every team member, from management and sales to operating technicians, has insights into the process — offering project visibility and improving communication. This transparency reduces the number of questions and overall communication required on each order, increasing the possibility of on-time and accurate shipments.

This allowed Extol to rapidly turn around more quotes with better accuracy. Plus, improving the accuracy made budgeting more predictable for Extol as the company's specific requirements and operating costs were configured into CO-AM. Tied to this predictability is traceability, as the system could now track quality records that are traceable to a single part. Items such as material certifications and lot numbers are tied directly to each order. These efficiencies lay the groundwork for more customer-focused innovation by Extol's teams, allowing them to shift focus from firefighting to helping customers find and develop valuable applications for 3D printing.

As a result, over 1,200 orders were fulfilled in 2022 with an estimated 97% on-time shipment rate. Hundreds of customers have been supported and Extol's teams have saved around 10 hours per month in terms of labor related to communication and order management. “CO-AM has provided numerous benefits to our operation. But most importantly, it increases our effectiveness in accurately delivering orders that meet our customers’ requirements," says Kyle.

“We want our customers to instantly see the benefits of investing in our software platform. That's why our customer operations set up a core team made up of users and CO-AM team members,” states Lara Janse Van Vuuren, Technical Program Manager at CO-AM. “We also regularly schedule training, discovery, and working sessions to help ensure success with all our clients. And we constantly optimize CO-AM's framework on an ongoing basis so that the system's functionality supports the critical business requirements and objectives that our clients, like Extol, expect.”

CO-AM's ability to make a difference in Extol's AM infrastructure and business is clear to see. Realize your vision and shape your company's AM future with a smart, digital, and connected end-to-end software solution.

Share on: