CUSTOMER STORY

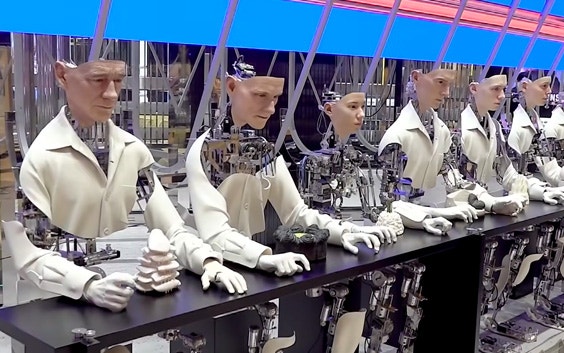

Are These Androids Dreaming of Electric Sheep? Gluck Produces Life-Like Robots with Materialise Software

Robots are big business in South Korea. The country has the world’s highest robot density across various manufacturing industries, with 932 per 10,000 employees.1 And it isn’t just in manufacturing: humanoid robots are also appearing in commercial settings. Androids aren’t limited to science fiction; you can see them on display in department stores, exhibitions, and other busy places — capturing the public’s attention and imagination.

Take these robots manufactured by Gluck, a 3D printing service provider, that have gained millions of views online. How did they make such amazingly detailed androids? Ingenuity, skill, and software focused on optimizing resin 3D printing. We spoke to Jaeok Hong, CEO, and Gwanghyun Jang, Teamlead at Gluck Co., Ltd., to learn more about these humanoid machines, how Gluck used Materialise Magics and e-Stage support generation software for this unique job, and the company’s plans to scale its 3D printing production. By undergoing a complete digital transformation, Gluck can ensure their other applications receive the same care and craftsmanship.

Is it a man or a machine?

Gluck has recently gained much attention by producing photo-realistic humanoids using additive manufacturing (AM). “Public interest in humanoid machines and the 3D printing process is growing, but I was personally surprised by the reaction globally,” says Jaeok Hong.

The team was hired based on their extensive knowledge of AM and the quick, end-to-end service they can provide — from 3D design modifications to post-processing. “Our expertise regarding suitable materials and how to optimize AM’s software settings were considerable advantages for us. Plus, we have 30 industrial grade 3D printers, allowing us to meet the strict turnaround time our client expected, so they could provide these units to their end customers,” says Gwanghyun Jang.

They used stereolithography (SLA) to produce these androids. SLA is one of the most widely used 3D printing technologies. Its flawless surface quality and ability to create fine details make it ideal for high-quality visual models with complex aesthetic parts. “SLA was a prerequisite for this project; we’re able to achieve high reliability, high-quality surface roughness, and a large printing output,” states Gwanghyun Jang.

To manage such an intricate project, Gluck optimized Magics to seamlessly work with their production workflow and e-Stage for support generation. Both were essential, as Magics simplifies data and build preparation, allowing them to handle enormous amounts of data — while e-Stage for resin automatically generates the necessary lightweight structures for the models, reducing the risk of build failures.

“With software like Magics and e-Stage, we managed a high-quality, stable, and reliable production workflow.”

— Gwanghyun Jang, Team leader at Gluck Co., Ltd.

“We produced ten humanoid robots and completed the printing process within 24 hours. Post-processing and painting were carried out around three days after printing. The main benefits of 3D printing were staggering: fast lead times, print-on-demand, inventory-free production, the freedom to choose different materials, its durability, and the opportunity for aesthetic post-processing, to name a few. We’re really pleased with the result.”

Gluck expands SLA manufacturing to scale serial and mass production

The success of this project is just the start. Gluck is adding 50 SLA machines to boost production, expanding to 80 in total. “We’ve been using industrial SLA printers for the last five years and operate with many machines. Additive manufacturing is growing in Korea. Based on our understanding and experience in 3D printing, we’ve optimized our workflows and processes to meet this demand. This expansion enables us to provide time and cost efficiencies that will positively impact our customers,” says Jaeok Hong. As design and engineering solutions and AM consultation are becoming increasingly important in the country, Gluck sees this as an excellent opportunity and the main driving force to supercharge their business. Specialized 3D printing software, such as Magics and e-Stage, played a significant part in this strategy.

“We had 3,000 customers last year, and it was challenging to manage them efficiently. Using Materialise’s software solutions, we managed a high-quality, stable, and reliable production workflow. The team helped us onboard quickly and trained us to utilize the software efficiently.”

Squeezing the full capabilities out of these software solutions to make use of AM’s extensive benefits bodes well for other applications edging toward complex and intricately designed, small series products via serial production. Software that integrates management and quality assurance processes is vital for on-demand mass production, a service Gluck wants to offer. “Software built to track and manage AM is critical for improving our full production process,” explains Gwanghyun Jang.

Materialise CO-AM — adding business automation to Gluck's existing workflows

Gluck plans on expanding at home and abroad — with new manufacturing facilities for the US to be constructed by 2026. To prepare them for this acceleration in production, they’ve decided to use CO-AM to unify and streamline their systems. “We expect CO-AM to bring additional automation, such as automated data-based processing, to our communication chain, allowing us to build automatic quotation, payment, and rapid delivery systems. The data and indicators accumulated by CO-AM will be important criteria for us when carrying out value judgments and will support our decision-making process. Furthermore, we’ll be able to dramatically increase customer satisfaction, giving us a competitive edge,” says Gwanghyun Jang.

CO-AM’s ability to effortlessly integrate with Gluck’s existing AM process and specialized internal robotic process automation (RPA) system will bring even greater efficiencies for them. These automated systems will be connected and managed in one platform, freeing time for employees to handle more complex tasks. Gluck believes that CO-AM will strengthen its competitiveness in the long run, allowing the team to dedicate more resources to deliver clients high-quality mass-production consulting and different post-processing techniques.

With 3D printing software like Magics, e-Stage, and CO-AM, Gluck has the tools to carry out various business ventures domestically and internationally. For example, the automotive and tire industries have many limitations in their traditional manufacturing processes that AM could enhance by implementing new forms and textures. “Just like the 3D printing process, dedicated AM software has the versatility to be applied to many areas and applications. Jigs and tooling in the aviation industry, semiconductor inspection processes, and more, empowered by Materialise’s software. There are many ways to maximize its value.”

Manufacturing is undergoing rapid change, particularly in South Korea. Gluck aims to be at the forefront with its AM expertise and know-how, choosing the right material, process, and finish to fit the client's needs. And with AM software to help them throughout the entire 3D printing process — from data and build prep to scaling for serial and mass production in the future — it won’t be long until you see creations like these realistic robots in a shop window near you.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.