Technology

Multi Jet Fusion

No support structures, minimal post-processing, and high-quality materials: when you need high-performance polymer parts quickly, our Multi Jet Fusion 3D printing service delivers. With our ISO 9001-certified facilities and processes, a diverse portfolio of quality materials, and diverse finishing options, we produce even the most complex end-use parts on time and to your specifications.

Multi Jet Fusion 3D printing service

Whether you need functional prototypes or end-use parts, our MJF 3D printing service will help you maximize the benefits of this technology. As a proud member of HP's Digital Manufacturing Network, we’ve been fully qualified by HP and recognized for the excellence of our 3D production and quality processes.

What is Multi Jet Fusion used for?

Technical specifications

| Maximum build dimensions | Dimensions are unlimited as components may be composed of several sub-parts. The maximum build envelope is 370 x 274 x 375 mm |

| Standard accuracy |

|

| Layer thickness | 0.08 mm |

| Minimum wall thickness | 1 mm, but living hinges are possible at 0.5 mm |

| Surface structure | Unfinished parts are stone-gray and have a slightly grainy surface, with layers visible in some orientations |

Multi Jet Fusion materials

Choose from a selection of materials when you come to Materialise for your Multi Jet Fusion projects.

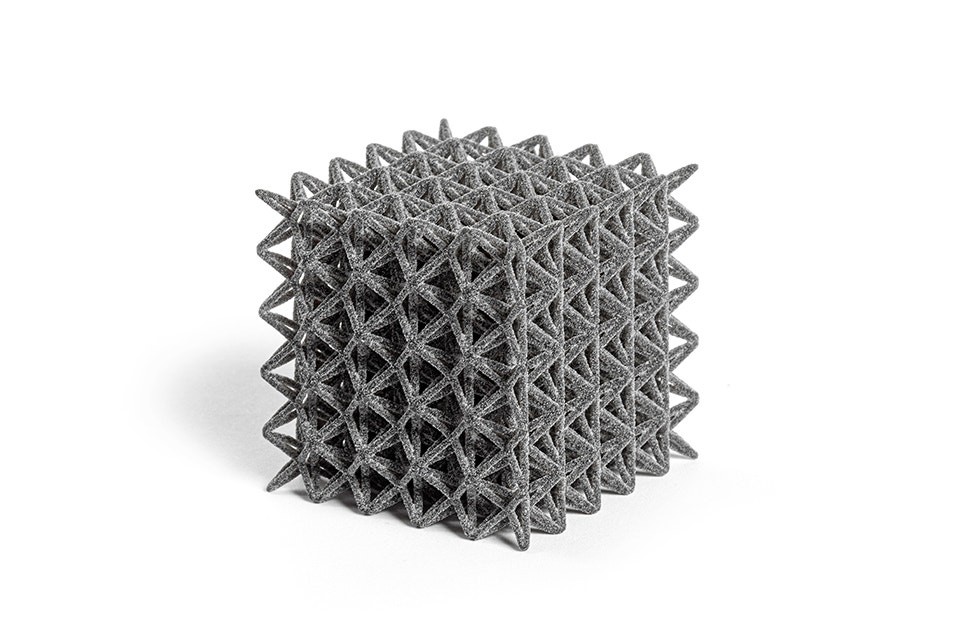

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

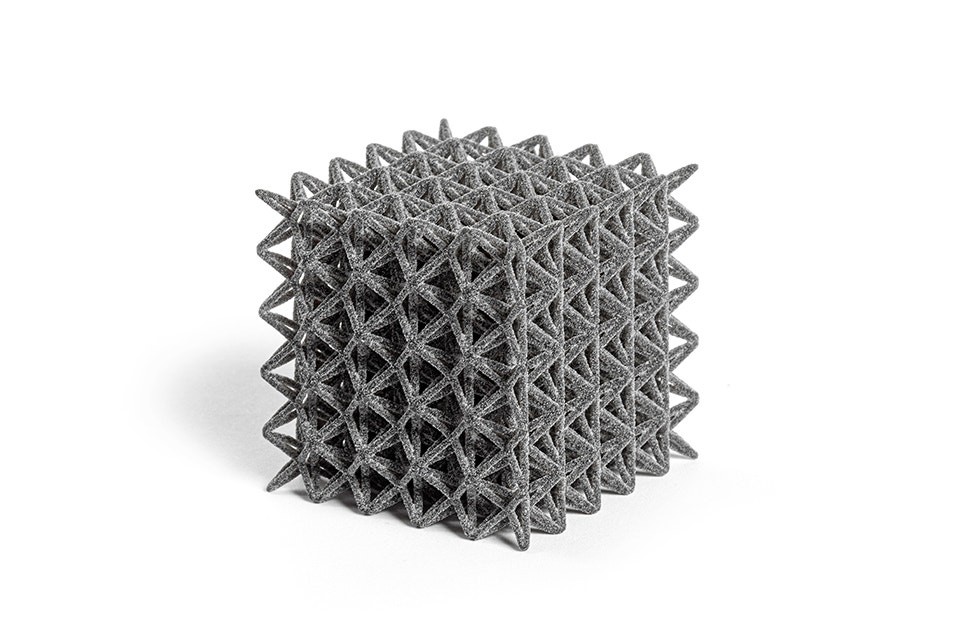

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

PA 12S

Technology

Multi Jet Fusion

Description

Combining an excellent level of detail and dimensional accuracy with minimal post-processing, this eye-catching material is ideal for fast iterations during prototyping or low-requirement series production.

Key characteristics

- High visual specifications

- Excellent dimensional accuracy

- Low post-processing requirements

- Max part dimensions: 370 x 274 x 375 mm

PA 11

Technology

Multi Jet Fusion

Description

Combining excellent mechanical properties with impressive surface quality and detail, this material is ideal for both series production and functional prototypes, especially in industries like medtech (O&P), aerospace, and automotive.

Key characteristics

- Flexible and stress-resistant

- Excellent surface detail and dimensional accuracy

- High density and isotropy

- Smooth surface quality with minimal post-processing

- Max part dimensions: 370 x 274 x 375 mm

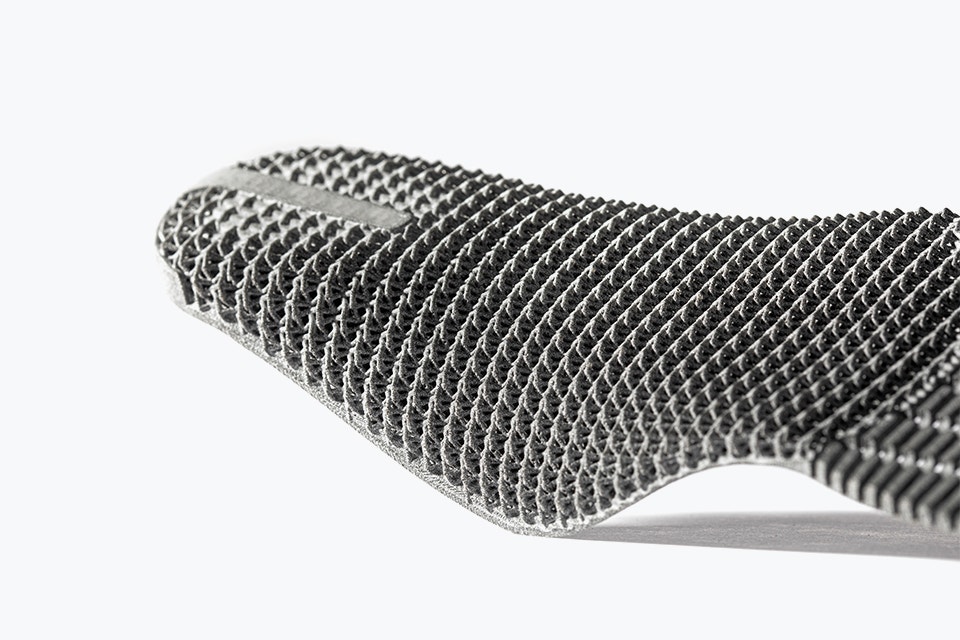

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

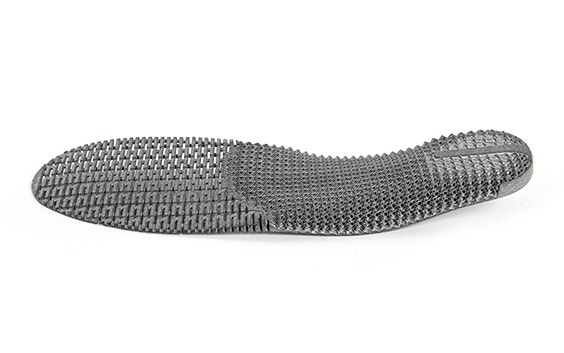

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

Work with us: discover our products and services

Want to bring Multi Jet Fusion into a future project? Discover the 3D printing services that can help you do it.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Train and learn

Get more from your next project with helpful resources dedicated to Multi Jet Fusion.