CASE STUDY

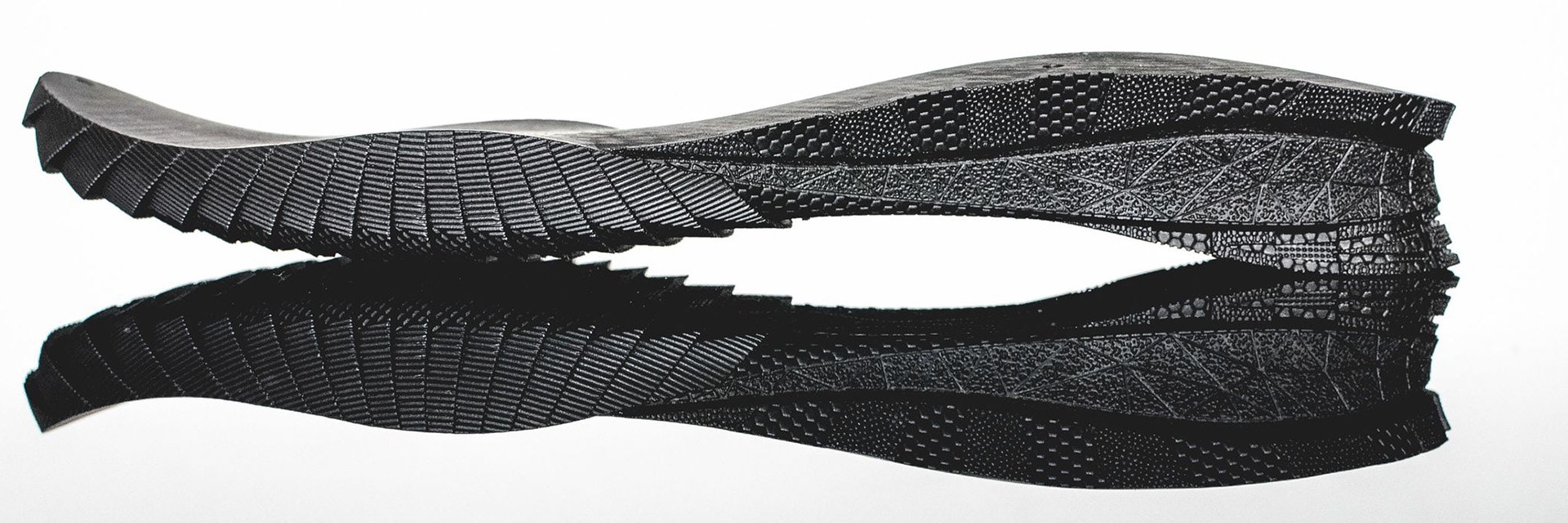

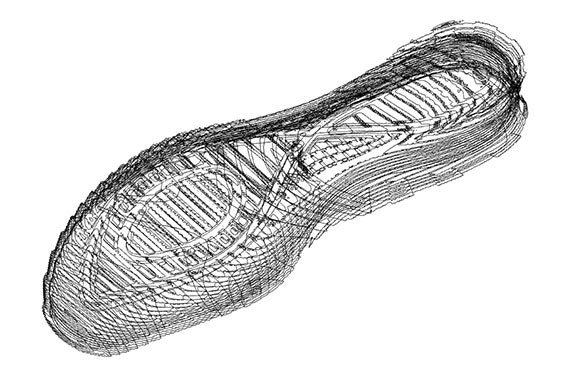

Texturing 453 Surfaces of a Shoe Sole: Discover Texturing

Shoe manufacturers often use a master to cast the soles of the shoe. Instead of creating a mold for each type of sole, the bigger shoe manufacturers nowadays 3D print the soles. Manually assigning a texture to each surface area takes a lot of time. In addition, you end up with huge STL file sizes that your computer can no longer handle.

Industry

- Shoe manufacturing industry

- Consumer goods

Key solutions

- Materialise 3-matic

- Materialise Magics

- Materialise e-Stage

- Materialise Build Processor

- Apply mass texturing instead of 1-by-1 texturing

The impact

Create a highly detailed master (including 453 textured surfaces) for casting a shoe sole

Materialise software guides the shoe manufacturer from design to printed part in a time- and cost-efficient way, allowing them to take full advantage of the disruptive possibilities of 3D printing.

A 3D-printed, textured master for casting

Discover how four solutions from the Materialise software backbone give shoe manufacturers a shortcut to repair the worst file errors, texture hundreds of surfaces, automatically generate support and finally keep those huge data sets manageable.

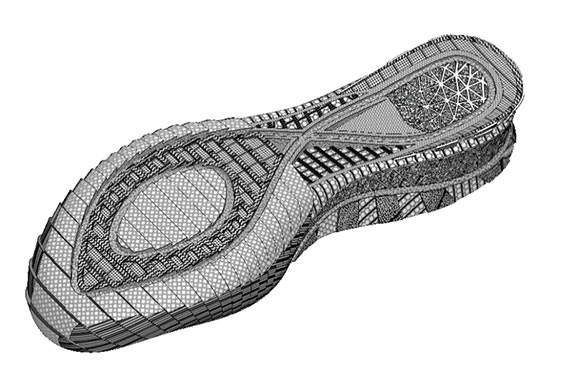

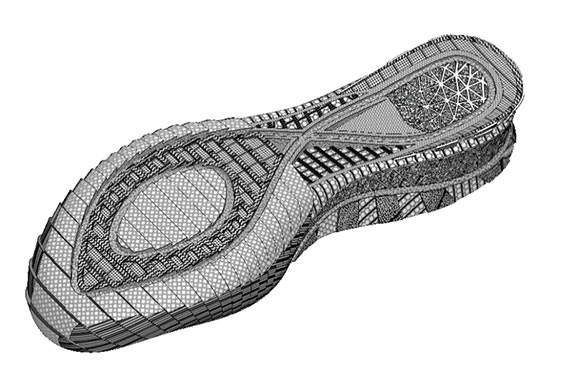

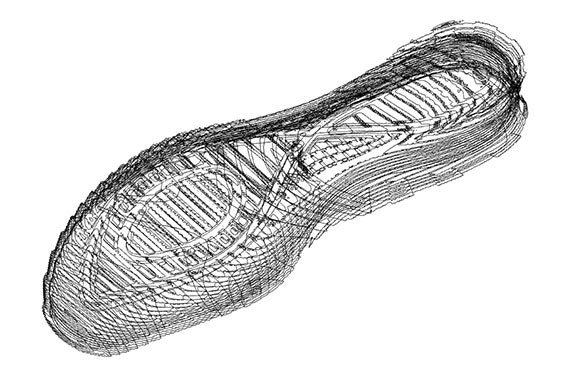

Texturing: 80% time savings

Applying textures one by one demands massive amounts of time when you need to texture around 1,000 surfaces. With the texturing module of Materialise 3-matic, hundreds of surfaces that need the same type of texture can be grouped in surface sets and textured with one click. In this shoe sole 453 surfaces were nicely textured and aligned, saving at least 80% of time compared to 1-by-1 texturing.

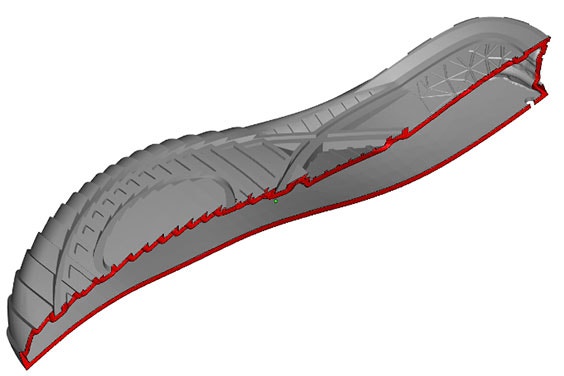

Data preparation: automatically repair

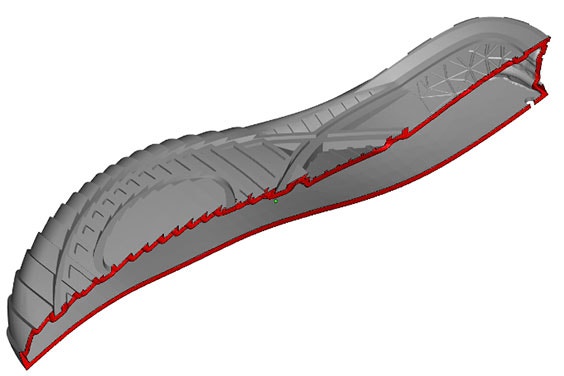

To print the shoe in the most cost-efficient way, we created a hollow version of the model and added holes for resin drainage. In addition, Materialise Magics was used to position the shoe sole on the build platform in an optimal way.

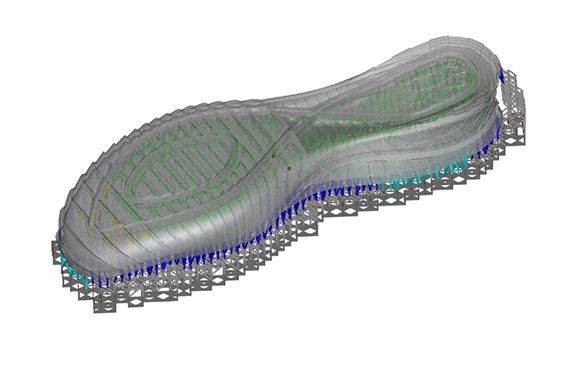

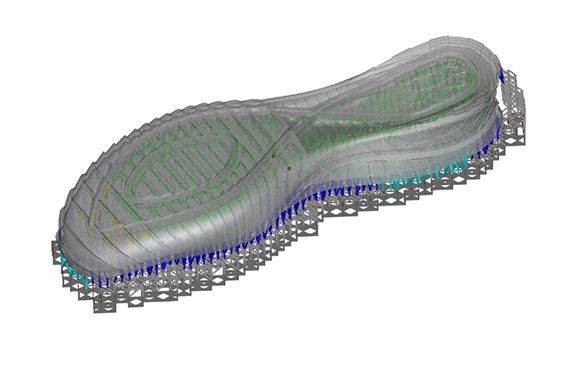

Automatic support generation: save 20 minutes per part

Manually generating support is a very labor-intensive job. With the automated support generation tool e-Stage, the support preparation time was significantly reduced. Using Materialise e-Stage can reduce data preparation time by up to 20 minutes per part, depending on the complexity and size of the part. The support was not limited to the outside, but also supported certain hollow regions inside the shoe. Thanks to minimal contact points, the finishing time was reduced as well.

Slice-based data processing: 5.8MB instead of 2GB

Applying textures or structures to a model can easily result in very large STL files which become difficult to manipulate, store and transfer. Thanks to the slice-based technology of the Build Processor, the demanding triangle creating to an intermediate STL file was skipped. The desired geometry was generated directly onto the slices, thus avoiding large data. 453 surfaces were textured on a 5.8 MB size STL file, resulting in a slice stack of only 50 MB. Thanks to the slice-based technology an STL file of around 2 GB could be avoided.

The final result was this stunning textured master!

Featured products and services

Generate lattices, create textures for an aesthetic finish, and achieve post-topology optimization.

Optimize and automate support generation with options tailored to different materials, technologies, and geometries.

Slice and send jobs to 3D printers based on machine-specific strategies or optimize custom scan path strategies with our software development kit.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Share on: