CASE STUDY

Tata Motors Improves the Efficiency of Their Prototype Production

With over 9 million manufactured cars, buses, trucks, and other vehicles, Tata Motors is leading the automotive industry in India. And by producing the majority of their output in their own country, they contribute to the ‘Make in India’ policy of the Indian government, launched to stimulate the country’s growth. As drivers of the Indian automotive landscape, they ventured to intensively apply 3D printing as a new technology for their prototype development, using both laser sintering and stereolithography machines. But how do they make sure they use these technologies in the most efficient way?

Industry

Automotive industry

Key solutions

Materialise Magics

Materialise e-Stage

Smart data prep

Support generation software

The impact

Print less defects and reduce material consumption of supports

Advanced repair tools and scaffold supports

Why 3D print car prototypes?

Producing prototypes was one of the first applications of 3D printing technology and the automotive industry pioneered this development. 3D printing in automotive allows businesses to produce parts faster than with conventional methods. Today, the technology is cost-efficient and offers highly accurate parts and a wide range of high-quality finishing options, leading to an incredible resemblance to reality.

The benefits are obvious. How about the challenges? Tata Motors, Engineering Research Centre-Prototype Manufacturing (ERC), discovered that a large part of their prototype volume problems was caused by support structures. Finding the optimal configuration for the supports required trial runs. In addition, insufficient data preparation led to build failures. Fortunately, our 3D printing software suite could help them to fix these issues.

The benefits of smart software

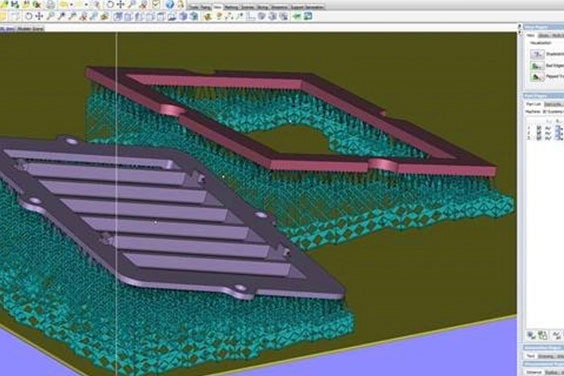

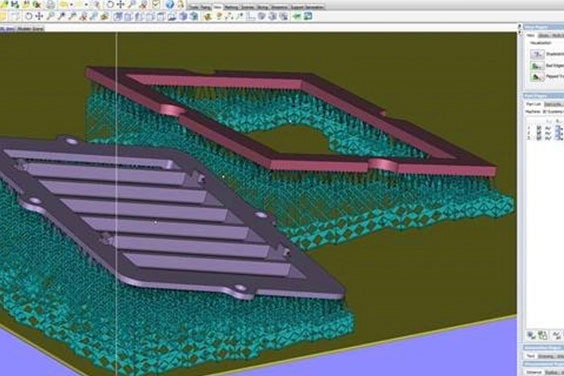

Tata Motors ERC currently uses Materialise Magics for its data preparation. They use it to convert CAD files to STL, fix all errors, cut, merge, hollow, label, and rescale parts – and much more. For their laser sintering production, they use the Magics Sinter module to automatically nest all parts at the nesting density and height of their choice. This software module speeds up data preparation, reduces powder consumption, and offers many ways to control the laser sintering process.

For their stereolithography production, ERC uses Materialise e-Stage, a software program that automatically generates support structures. This automation wipes out human errors and only places support where it is indispensable. The toothed connection points make support removal a lot easier, resulting in higher surface quality. In case texturing is needed, Materialise 3-matic software helps to create aesthetic and functional textures, patterns, and perforations.

Smooth 3D printing operations

“Materialise Magics, which is a part of the Materialise Magics 3D Print Suite, is very helpful software in that it provides advanced STL repair tools for fixing our files. It also gives us more confidence to 3D print parts without any defects or deviations, leading to innovative, high-quality products for our customers.”

— Yeole Hemkant, Senior Manager – ERC Prototype Manufacturing, Tata Motors

Backed by Materialise software, Tata Motors ERC Prototype Manufacturing, now produces 3D-printed prototypes that consume less material and are of higher quality. The support structures occupy around 30% of a part’s weight, whereas they weighed double or even triple before. Their data preparation process is sped up and generates fewer build failures.

All images: courtesy of Tata Motors

Featured products and services

Generate lattices, create textures for an aesthetic finish, and achieve post-topology optimization.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Optimize and automate support generation with options tailored to different materials, technologies, and geometries.

Share on: