CASE STUDY

Making a Difference in Metal 3D Printing: How e-Stage for Metal+ Reduces Support Structures by up to 85% and Maximizes Efficiency

To optimize their production processes and develop new, more complex geometries for large parts, the BÖLLINGER GROUP put Materialise’s e-Stage for Metal+ software solution to the test. The results: 60% less support material, 50% shorter data preparation time, and a significant reduction in post-processing. It highlights how automating support structure generation enhances the cost-effectiveness and quality of metal 3D printing.

Industry

Industrial additive manufacturing

Key solutions

- Materialise e-Stage for Metal+

- Design for additive manufacturing

The impact

- e-Stage for Metal+ is support generation software designed specifically for metal 3D printing

- Use less support material

- Shorten data preparation time

- Reduce post-processing

The challenge

Reduce the material waste, post-processing costs, and lead times of metal 3D printing

The BÖLLINGER GROUP Department for Additive Manufacturing, founded in 2012, has helped the company develop from a trader of high-quality technical components into a leading additive manufacturing supplier. With one of the world's largest laser powder bed fusion (LPBF) build rooms, the BÖLLINGER GROUP offers customized solutions for complex components. The company supports its customers right from the development phase with comprehensive engineering expertise and implements their functionality and functional integration requirements in a targeted manner.

It’s an industry in which metal 3D printing offers both immense opportunities and well-known challenges: complex geometries, strict precision requirements, and the constant need to make processes more efficient. Conventional processes quickly reach their limits, especially with very large and sophisticated components — material waste is high, post-processing is costly, and production times are long. In addition, generating support structures requires a high level of knowledge and extensive experience. They need specialist personnel to develop the right support strategies, which leads to multiple iterations and considerable effort. This is where Magics e-Stage for Metal+ can make a difference.

"Our previous methods were simply not efficient enough to keep pace with the growing requirements," explains Florian Kellermann, Production Manager LPBF within the BÖLLINGER GROUP. “We needed a solution that not only optimized our processes but also opened up new design possibilities."

The solution

Transforming AM processes with Materialise e-Stage for Metal+

In collaboration with Materialise, the BÖLLINGER GROUP decided to evaluate e-Stage for Metal+ with a comprehensive test phase. The goal was to speed up processes and reduce material consumption while improving the dimensional accuracy and quality of their components.

With the support of Dennis Bieber, Application Engineer at Materialise, they gradually integrated the software into the existing workflow and put it to the test through targeted benchmarking — an important phase for any customer. It allowed the BÖLLINGER GROUP to recognize the benefits of e-Stage for Metal+ and ensure that the software delivers the desired results. They could test, adjust, and optimize the entire process before making a final decision, giving them the confidence to make the purchase. There’s real added value — both in terms of productivity and profitability.

"Working with the BÖLLINGER GROUP was a great opportunity to demonstrate the strengths of e-Stage for Metal+ in a real production environment," says Dennis. "Our aim was not just to provide them with a tool but to help them realize the full potential of the process."

The evaluation consisted of a series of tests, carried out in stages. The team began with a simple component to familiarize the user with the software environment and demonstrate basic printability.

Testing soon moved on to a second, more complex component. Here, the team compared two parts: one prepared using e-Stage for Metal+ and one using the conventional Materialise SG+ module.

The results were remarkable: despite the component's increased complexity, support volume was reduced by 85% compared to conventional block support. Although the exposure time increased by around 13%, this was due to the fact that only every second layer was exposed with the block support. Another advantage was seen when removing the support structures: the working time was reduced by 45%, saving both time and costs while leading to a much cleaner workplace. Significantly less powder residue improved the working conditions considerably.

"The occupational safety of my colleagues is always our top priority," explains Florian. "Less powder also means cleaner air for us."

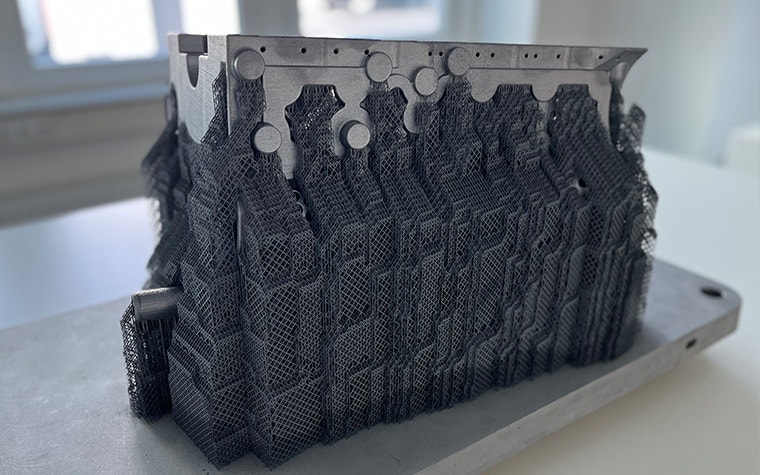

As the test progressed, the complexity and size of the components gradually increased, as did the demands on the Materialise experts. The highlight of the evaluation was the implementation of an 18-kilogram crankcase. Produced using Colibrium Additive’s X Line 2000R — a dual-laser printer with a build chamber of 800 mm x 400 mm x 500 mm (160 liters) — it proved a sizeable challenge, both in terms of dimensions and complexity.

These factors made the results of this test particularly important. The successful production proved that e-Stage for Metal+ is capable of mastering even extremely demanding projects, delivering maximum efficiency and precision while increasing cost-effectiveness.

Challenges and lessons learned

The test phase provided valuable insights for future optimizations, such as giving greater consideration to screw holes in the support structures and improving the flexible adjustment of support cone thickness. The Materialise development team immediately implemented the latter during the test phase and is also developing the upstream adjustment of cone support profiles, which would offer additional functionality.

"The test series not only showed us the strengths of the current technology but also its limitations," explains Florian. "However, by working closely with Materialise, we were able to develop targeted solutions to overcome these challenges. The integration of the new module also required a rethink: our previous workflow had to be adapted. In practice, this means, for example, that we first place and align the components on the build platform before automatically generating the support structures."

The results

60% less support material, 50% faster data prep, and a significant reduction in post-processing

What makes the production of the crankcase so impressive is that it is officially the largest and heaviest metal 3D-printed part made with Materialise e-Stage for Metal+ so far. It’s a clear demonstration that the software makes it possible to realize designs that were previously considered impossible. The automated support structures provide stability during printing and can be removed quickly and precisely afterward. Additionally, the support volume was reduced by 60%, leading to significant material savings. At the same time, data preparation time fell by nearly 50%, noticeably accelerating production.

"It was amazing to see that this software is capable of realizing such complex components," reports Florian. "The crankcase is a prime example of how innovation can overcome boundaries."

The largest metal printed part to date

The crankcase is also a prime example of what the future holds for lightweight construction in the automotive industry. The aim of the project was to reduce weight by up to 40% using innovative manufacturing methods such as LPBF while improving the efficiency and service life of the component. Thanks to additive manufacturing’s design freedom, the designers could integrate new cooling and lubrication concepts, such as arterial cooling, which contribute to more efficient heat dissipation. This innovation would not have been possible with traditional manufacturing methods.

It’s further proof that powerful software solutions such as e-Stage for Metal+ help to put forward-looking innovations into practice. In particular, the automated support structures and the significant reduction in material costs and post-processing time made a decisive contribution to the success of this ambitious project.

"e-Stage for Metal+ has not only improved the quality of the components but also considerably simplified post-processing," emphasizes Dennis. "The reduction in manual intervention ultimately saves time and money."

A turning point for the Böllinger Group

The introduction of Materialise Magics e-Stage for Metal+ has proven to be a real turning point for the BÖLLINGER GROUP. The automated workflows have not only reduced production times and material costs but also increased the company's ability to innovate.

"With e-Stage for Metal+, we have found a solution that not only increases our efficiency but also enables us to implement completely new design ideas," summarizes Roman Lengsdorf, CTO of the BÖLLINGER GROUP Department for Additive Manufacturing. "This technology is more than just a tool — it is a key to our future."

The final calculation of the ROI proves that the annual costs for the e-Stage for Metal+ add-on module quickly pay for themselves. A sample calculation of a customer order showed that using the new module made it possible to increase the number of pieces on a construction panel from 8 to 12, reducing the price per component by around €1,000. It’s a win-win situation for both the BÖLLINGER GROUP and its customers.

Dennis adds: "The results speak for themselves. It is impressive what is possible when technological innovation, practice-oriented application, and bundled expertise go hand in hand."

An exciting future

The results don’t just make for exciting reading: they actually exceeded the group’s original targets. Data preparation time, construction time, and post-processing time were significantly shortened, material consumption was reduced, and delays were minimized. In addition, the BÖLLINGER GROUP is improving work safety, expanding and securing its competitive advantages, and achieving rapid amortization of the investment. "This makes e-Stage for Metal+ an absolute must-have, and we can no longer imagine life without it," emphasizes Florian.

Thanks to the BÖLLINGER GROUP, Materialise gained important practical experience in implementing the entire additive process chain using e-Stage for Metal+ while increasing the internal know-how regarding the use of software, especially for large and complex additive components. These findings are used to directly improve the solution itself.

This collaboration is an impressive example of how strategic partnerships and modern software solutions can revolutionize additive manufacturing; companies can not only master existing challenges with the right technology but also set new standards.

Featured products and services

Automatically generate metal support structures to reduce human error and save time during build prep and support removal.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Share on: