EXPERT INSIGHT

30 Years of Materialise: Disrupting Traditional Product Development with 3D Printing

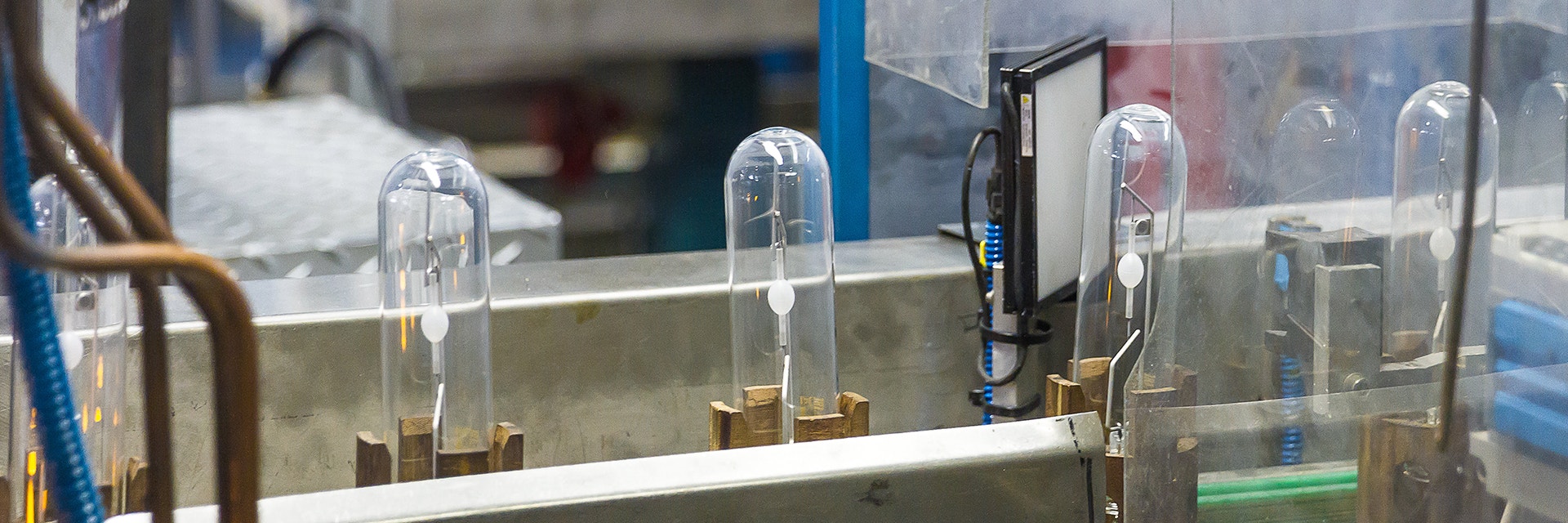

When Signify (previously Philips Lighting) invited the Materialise team to observe their production line to see where 3D printing could help them innovate, they had no idea that redesigning two devices used on the line would save them around €89,000 a year through operational benefits alone.

With a fresh new re-design manufactured by 3D printing, the devices are stronger, lighter, and made of fewer parts, which simplifies any repairs they might need. Using the winning equation of reduced cycle time paired with increased production, Philips Lighting was able to continue their innovation through the design freedom that comes from additive manufacturing (AM). It was a true “lightbulb” moment for the master lightbulb makers and greatly influenced the way they think and work since then.

Traditionally, product development for conventional manufacturing technologies is a long and linear process, rife with limitations. With the agility from AM and the AM know-how and re-design from the Materialise Design and Engineering team, Phillips Lighting was able to bypass pencil and paper and head straight to design and fast reiterations. 3D printing is enabling companies to think boldly about how they can improve their processes or products through design as AM allows complete design freedom.

As Materialise is celebrating its 30th anniversary this year, we are taking a look back at the most meaningful innovations over the company’s history with a series of blog posts. This time we are focusing on how innovation in product development and design can alter the course of an entire industry with AM.

A new way to prototype

3D printing first conquered the prototyping world before going on to other applications. It has emerged as a reliable option to help speed up the prototyping and functional testing for parts that will be traditionally manufactured. Designers needed a way to rapidly test out new shapes so they could “fail fast, learn fast” and simplify reiterations as they tested and validated ideas or concepts. One of the main differences is the way that we utilize 3D files in a digital process chain. After being designed in CAD, Magics is our data and build preparation software where users can prepare their parts to be 3D printed successfully. It is essential in helping with better build position and ensuring good wall thickness for optimal prints. Once validated, the prototype has the possibility of going on to be produced traditionally. This meant saving time and money from waiting on traditional methods, such as a mold, that often took months to create with each iteration. Now that such rapid prototyping was available, companies could accelerate their design in the production process.

Expanding design processes

Customarily, design engineering follows the concept of Design for Manufacturing (DFM), which is based on a collection of different conventional manufacturing methods such as milling, drilling, or forging — examples of subtractive or forming manufacturing. To develop for these methods, designers keep in mind the limitations of the techniques. However, this is still the most cost-effective method of mass manufacturing today.

Within the last 30 years, DFM went from overcoming the manufacturing limitations of traditional technologies to designing for opportunities with AM. AM gets its name from the production process where material is being added on as opposed to the traditional subtractive or forming techniques. It has proven to be a cost-effective and fast alternative to produce small series and complex or personalized parts. Today, there are two ways of designing, DFM and Design for Additive Manufacturing (DfAM).

Designing for additive manufacturing

With AM’s freedom of design, one can create an optimized design that makes maximum use of AM’s unique capabilities. It is giving rise to more organic shapes — closer to what one might see in nature. The Lattice Module is one of these new advances and is inspired by the bird bones, strong but lightweight, and enabled through 3-matic.

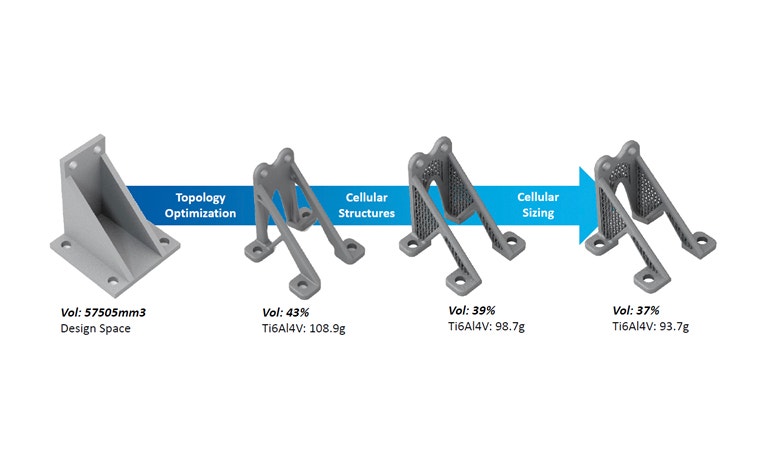

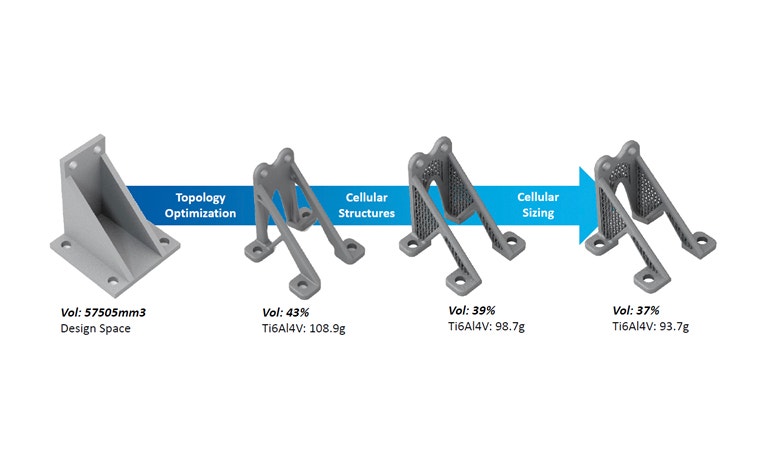

Topology optimization is another example of taking design notes from nature. It takes a 3D design space and whittles away material to achieve the most efficient design. Rather than the usual design constraints, it figures out the exact amount of material needed to develop a certain load path, which often creates very organic-looking shapes. 3-matic then changes the topology-optimized results back into a suitable CAD file so the workflow continues uninterrupted. The GE fuel nozzle that went from 20 painstakingly welded pieces to just a single 3D-printed piece that is 25% lighter and five times stronger is the perfect example of how the DfAM enables companies to merge assemblies and innovate like never before. "When designing for applications, there is less stress on how to manufacture the ideal shape — AM can simply create the ideal shape,” says Manuel Michiels, former Software Innovation Manager.

Evolution vs. revolution

Today, depending on its application, 3D printing can be a tool to support product development changes or a catalyst to change an entire industry. In the case with Airbus, they have tight timelines to retrofit their plane interiors and needed a smart, fast, and flexible solution to produce spacer panels for the overhead compartment. Materialise collaborated with them to redesign the panels for AM, and with the optimized shape of the brackets, they were able to reduce the weight by 15%. This made them Airbus’ first cabin parts with full bionic design certification. Additionally, with Materialise's certified additive manufacturing, they were able to meet the stringent requirements of the airspace authorities. This product evolution was supported by re-designing for AM.

Back in the early 2000s, Phonak realized a process that would forever change the hearing aid industry. Originally, making personalized fit hearing aids was a labor-intensive job that required a niche group of artisans and a lot of back-and-forth with the client to achieve a comfortable fit. When they collaborated with Materialise, they were able to use Rapid Shell Modeling (RSM), which allowed them to take an impression of the client’s ear canal and scan and produce a file in as little as six minutes. The shells are then prepared for an efficient build using Magics, printed, manually finished, and then the clients have a great-fitting pair of hearing aids made to fit their exact ears. Today, around 99% of the world’s hearing aids are made using this method. These days, similar revolutions enabled by AM are happening in the eyewear industry and the footwear industry. Both evolutions and revolutions are being carried by the added value that comes from the application of AM.

Adding value without compromising quality

The Materialise Design & Engineering team follows a formula to ensure that we are truly bringing added value with our solutions for customers. We try to raise the level of performance and how the part interfaces with other parts, all while bringing down the level of harmful elements and the cost. Balancing out the equation and looking at AM from every angle possible to attain the best solution is our goal during each collaboration.

To get started in AM and revolutionize your product design with added value, clients can choose to use our technology-neutral software that works across different systems, meet with our Design & Engineering team, or start a Mindware program. The different software has been built on 30 years of AM experience and insights and is the perfect tool to support your product development, from optimizing the design to the ideal production methods. Our consultancy service, on the other hand, brings AM veterans to the table with you to fully understand your business needs and challenges. They’ll be able to answer all your questions about feasibility and sustainable scalability and support you with knowledge and expertise throughout your entire AM journey. The Design & Engineering team will be able to answer any product development or production questions to get you the added value that makes your design truly revolutionary.

The future is in revolutions

As we look forward from our thirty-year mark, we see many opportunities to advance product development. Like with the hearing aids, we expect a lot more customization will be implemented as it is now a feasible solution with optimal results for customers. Many companies have been hesitant to explore 3D printing because of perceived quality or cost issues, but as case after case presents itself with companies saving money and time, like GE, Philips Lighting, and Phonak, it is quickly becoming a worthwhile investment of time to see what re-designing prototypes or products with AM can do for your company.

“Sometimes AM can be used to create a design evolution, but AM can also generate an application revolution where it becomes the catalyst to change the way of designing, manufacturing, and all the services around the product.”

— Dries Vandecruys, Materialise Design Engineer

Whether it is through Materialise software, Design & Engineering services, or our consultancy service for a true 360 collaboration effort, we will be there to bridge the gap so companies can have a smoother transition into AM. We look forward to helping more companies realize their AM solutions by enabling Design for Additive Manufacturing to facilitate more “revolutions” that balance the scales — becoming a true added value and reshaping entire industries.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.