CASE STUDY

Airbus Gets on Board with 3D Printing

When it comes to retrofitting aircraft, time is of the essence. But when newly designed elements in the cabin need to be integrated with existing components, spacer panels like those at the end of overhead compartments sometimes have to be adapted or redesigned. With tight retrofit timeframes to meet, Airbus was looking for a quick and smart solution to produce panels in small batches. Materialise’s aerospace manufacturing facility, with tailored post-production processes, provided the ideal solution.

Industry

Airbus

Aerospace

Key solutions

Certified additive manufacturing

Fused deposition modeling

Ultem 9085

The impact

Faster lead times

Optimized design

The challenge

Produce small-batch custom parts to meet tight timeframes and quality requirements

When an airline updates the layout of its cabins, there are often gaps between the existing and new components. These need to be bridged with custom panels to create an attractive, seamlessly finished interior. With the clock ticking until the aircraft can be back in the skies generating revenue, finding a smart way to produce the new parts — which are typically needed in very limited quantities — is of the utmost importance.

Traditionally, new plastic parts are manufactured using custom-made injection molds. This process is relatively complex, especially as many of the components are highly specialized. With slow lead times and a high cost per part — given the limited numbers of parts needed for a typical retrofit — Airbus was keen to find a faster, more cost-effective solution for the spacer panels located alongside the overhead storage compartments in their commercial aircraft.

But cost and lead times, however crucial, are not the only consideration when dealing with the aerospace industry in general and commercial aircraft cabins in particular. As well as having to meet stringent quality requirements to be considered flight-ready, they also have to meet exacting aesthetic standards — Airbus had integrated 3D-printed parts in their A350 XWB airliner in the past, but never in places where they would be visible to passengers. This was a chance to take 3D printing across the next frontier and into the aircraft cabin.

The solution

Manufacturing for aerospace with tailored post-production finishing

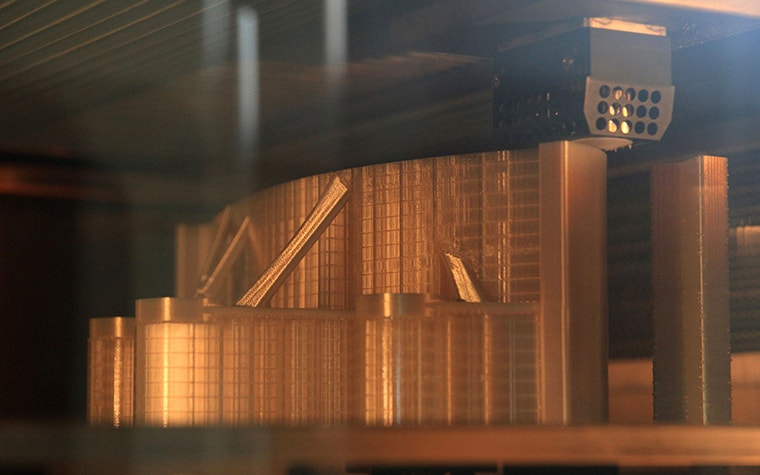

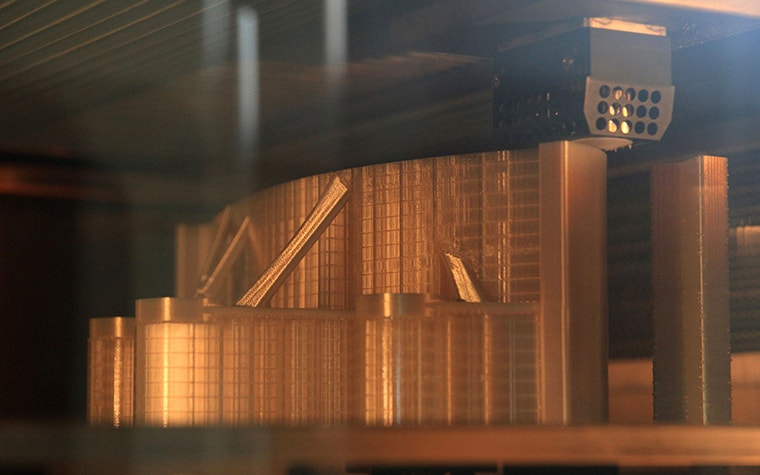

Directly producing the spacer panels using 3D printing brought many crucial benefits for Airbus, the most obvious of which was lead time. For small-batch series and customized parts, aerospace 3D printing offers a drastically faster time-to-market than conventional manufacturing, as prior tool production is not required.

“We think of this project as a great example of how we can serve the aerospace industry. It demonstrates how Materialise provides an end-to-end process that goes beyond the 3D print.”

— Erik De Zeeuw, Aerospace Market Manager at Materialise

Design optimization was another welcome benefit. Whereas internal structures like lattices add complexity and cost with the traditional injection mold techniques, 3D printing software could handle this with ease, making it possible to realize lightweight bionic panels and optimize the mass of the components.

In terms of finish, Materialise’s post-production processes ensured the 3D-printed parts met Airbus’ strict aesthetic requirements — once produced, the panels were then painted to Airbus cabin requirements, all using flame-retardant Airbus-approved materials.

Erik De Zeeuw, Aerospace Market Manager at Materialise, summarizes by saying, “We think of this project as a great example of how we can serve the aerospace industry. It demonstrates how Materialise provides an end-to-end process that goes beyond the 3D print. It’s about the strict quality process and incorporating every detail of the requirements from design to finishing.”

The foundation lies in a carefully honed quality management system, the results of which are evidenced by the number of certifications the Materialise manufacturing facility holds: ISO 9001 for quality management, ISO 14001 for environmental management, and the two critical ones for the aerospace industry quality management: EN9100 and EASA part 21.G, the latter of which is a Production Organization Approval (POA) from the civil aviation authority.

The result

Flight-ready, aesthetically perfect panels that are 15% lighter

Working hand in hand with Airbus, we produced the company’s first-ever cabin-ready 3D-printed parts. Combining additive manufacturing and our post-production processes, the panels passed all Airbus Cabin Trim and Finish checks. And thanks to the design optimizations made possible by 3D printing, the spacer panels achieve full bionic design certification — Airbus’ first cabin parts to do so and a successful result of the company’s ongoing efforts to optimize part weight. Compared with the original design, intended for conventional production methods, the 3D-printed panels are 15% lighter.

Close collaboration between Materialise and Airbus was key to the success of this project. As Erik points out, “Our goal at Materialise is to be a trusted and reliable additive manufacturing supplier to Airbus. We do this by innovating together in design and production processes with our software and AM know-how, but also by seamlessly integrating Airbus’ own way of working.”

With this project, additive manufacturing showcases the enormous benefits it can offer to airlines with an unrivaled combination of affordability, quality and aesthetics, and fast lead times.

Featured products and services

Share on: