Small Series Production

Transform your approach to low volume production with 3D printing

Whether you’re printing one part or one thousand, simple or complex, small series manufacturing goes further with 3D printing. Take advantage of unmatched design freedom to create new, improved parts; save time and money with a digital inventory and minimum order quantity of one; reduce assembly and lead times by designing in functionalities; and rely on our expertise in series production to make it happen.

Why choose 3D printing?

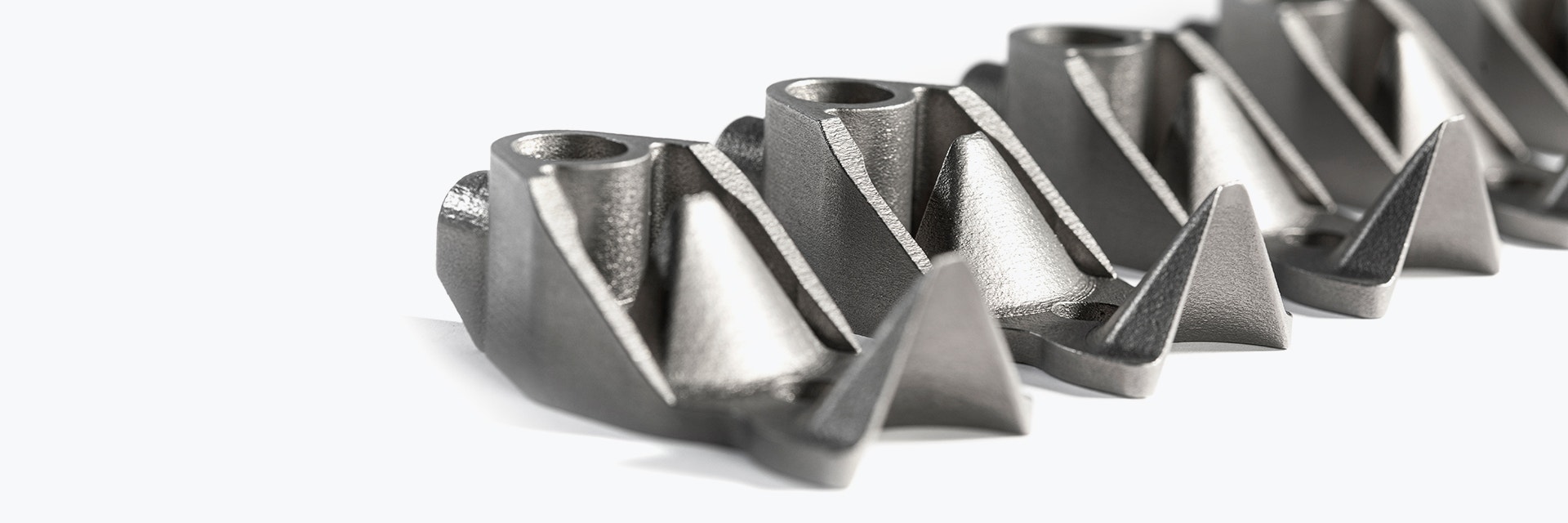

Improve part performance

With 3D printing’s design freedom, you can improve existing parts or envision something entirely new. Reduce assembly time by integrating multiple components into a single design; improve performance by designing in new functionalities that would not be possible with the constraints of traditional manufacturing; and do it all faster than ever through affordable design iterations.

Save time and money

Choosing 3D printing as your primary technology comes with fewer entry barriers than traditional manufacturing methods. Thanks to lower upfront costs and less need to invest in your production line through repairs, spare parts, and innovations, you can save both time and money by investing in additive manufacturing (AM).

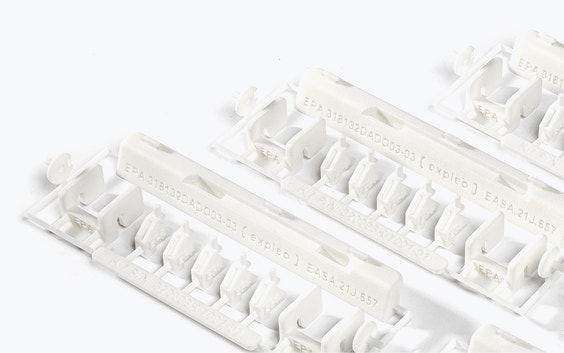

Optimize your supply chain

A digitalized workflow brings plenty of benefits to serial manufacturing, particularly when it comes to your supply chain. Take advantage of a minimum order quantity of one, on-demand manufacturing, and a digital inventory to ensure you produce or receive no more than you need, whenever you need it.

Our services for small series production

Ready to start your project with us? Discover our services, ideal for your application.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Small series success stories

Discover how additive manufacturing helped these companies make a difference through small series production.

Inspiration

Get inspired for your next project by looking at how others have used 3D printing for small series production.