Mass Customization

Offer truly personalized products and create unique customer experiences

The customer is always right — with 3D printing’s potential to make mass customization scaleable and economically viable, you can ensure every product is right for them, from tailor-made solutions to small series production. Take advantage of our knowledge to integrate reliable, repeatable, and fully digital workflows from scan to print and automate your design and order flow.

Why choose 3D printing?

Automated customization from scan to print

With a digital workflow that includes design automation and optimized printing processes, you can take advantage of seamless, automated mass customization from start to finish. By digitalizing manual processes, you’ll break down barriers to entry, lower the cost of innovation, and make your production reliable, repeatable, and faster than ever.

Revolutionize your product strategy

Thanks to unmatched design freedom, innovation is the backbone of 3D printing. With the benefits of this technology, you can diversify your product line, reach into untapped markets, and bolster your market share by creating complex, innovative products that cater to the individual consumer.

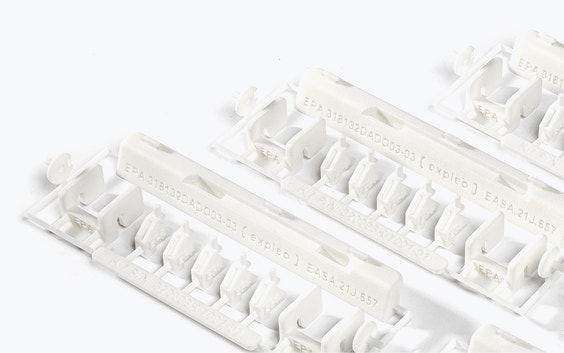

Lean manufacture: series of one

With 3D printing, mass customization becomes an entirely digital process — you can print on demand or in short production runs with no minimum order quantity or set-up costs. While too costly through traditional manufacturing methods, 3D printing makes mass customization lean and affordable.

Tailor-made designs

One-size-fits-all really fits no one. With the design freedom of 3D printing, you can design and create products that offer your customers what they want and need — personalized to their tastes, current trends, and even their anatomy.

Our services for mass customization

Ready to start your project with us? Discover our services, ideal for your application.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Mass customization success stories

Discover how additive manufacturing helped these companies make a difference through mass customization.

Inspiration

Get inspired for your next project by looking at how others have benefited from mass customization through 3D printing.