CASE STUDY

How EOS 2x Production Capacity and Unlocked Manufacturing Oversight by Scaling Their 3D Printer Fleet with CO-AM

EOS, a global industrial 3D printing original equipment manufacturer (OEM), offers professional printers, materials for metal and polymer machines, and other additive manufacturing (AM) services to help them stay on top. When their Additive Minds applied engineering team started to scale globally, they needed a platform that connected their systems across regions, reduced back-and-forth communication between departments, and provided workflow visibility on past customer projects to enable them to meet their customers’ expectations and tight deadlines. That’s why they chose Materialise CO-AM as the ideal software solution.

“We’ve explored a variety of workflow solutions,” says Gregory Hayes, Ph.D., Senior Vice President of Global Additive Minds at EOS. “From internal software solutions to commercially available Kanban boards driven primarily for order acceptance emails. When we began to scale, we needed a powerful but lightweight production management system to streamline communication and make collaboration easier.”

Effective collaboration relies on clear communication. And for complex manufacturing processes, transparent communication fosters operational excellence by enhancing team awareness while streamlining workflows. Poor communication can contribute to a project’s failure, resulting in project breakdowns and costly delays.

EOS wanted to avoid such pitfalls, so they looked for a software solution that would provide a single source of truth (SSOT) regarding technical requirements for customer projects around the globe. And, the system also had to be a single source of data repository, containing the often iterative production strategy necessary to end up with the final component — in line with their customers’ application requirements.

Moving away from an email, Kanban-based solution toward a more streamlined process was the goal. The platform had to:

- Allow for future integration with existing software platforms, like Salesforce CRM

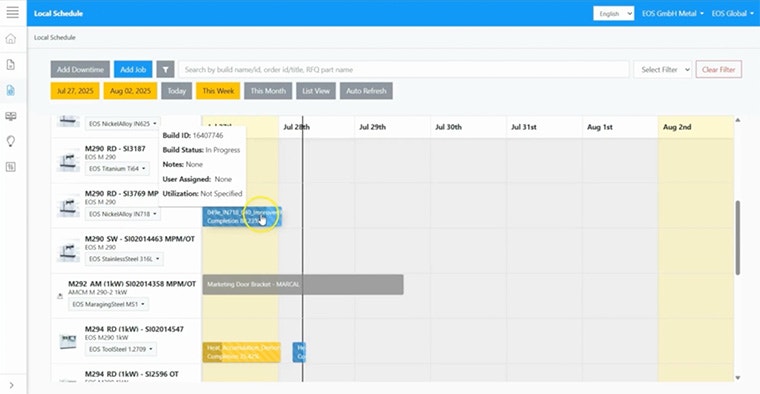

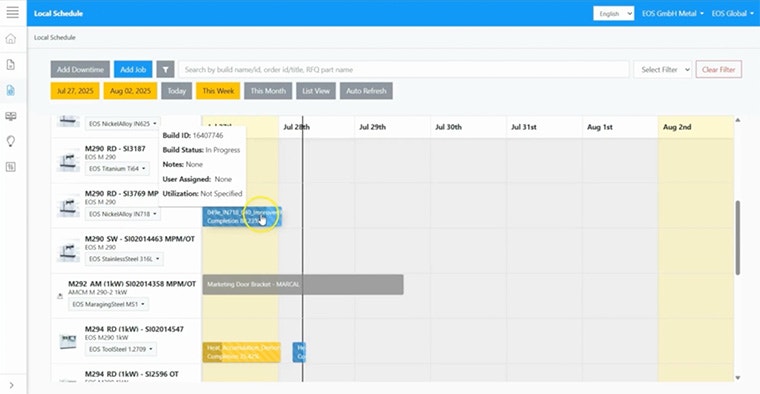

- Connect to the 3D printers in their network and monitor key metrics (such as scheduling, productivity tracking, data analytics, and distributed manufacturing)

- Enable easier collaboration between the sales and engineering teams in Europe, North America, and Asia–Pacific

EOS opted for Materialise CO-AM due to its interoperability, ease of use, and ability to create a digital thread across continents.

Challenge

Find software that enables operational excellence, awareness, and automation

EOS’ previous Kanban solution worked for a team of around 35 people. However, with the department doubling in size and spreading across different time zones, something more robust was necessary.

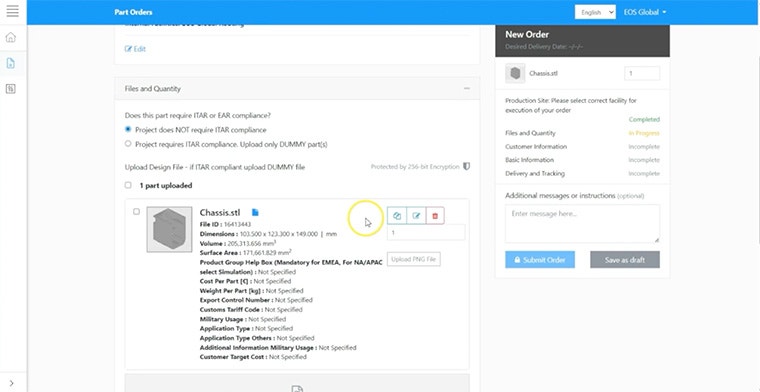

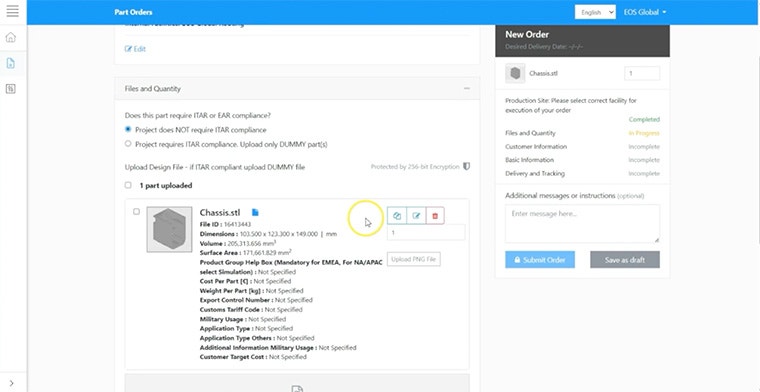

“Our client-facing engineering team works with customers from varying industries. This includes aerospace and government contracts, which require specialized cybersecurity requirements — specifically, ITAR-enabled solutions. We must print prototyping benchmarks to prove customer requirements can be produced with our printers. A growing team based in far-flung locations, such as Singapore, Munich, and Austin, meant we needed an AM platform to manage these complex workflows.”

They tested a dozen software solutions and decided on CO-AM (formerly known as Link3D). “We selected CO-AM because of its flexibility, ease of use, engineering feedback from testing protocols, company longevity, and price. CO-AM came out on top based on our weighted score system,” says Hayes.

CO-AM can operate independently or combine with the Materialise Magics pre-print software. Another possibility is to integrate CO-AM with other IT business solutions, like CRM, ERP, PLM, and more, to form a cohesive software ecosystem.

EOS uses CO-AM as a production management system, connecting a network of more than 50 3D printers for several years. In production, CO-AM equips AM process engineers, researchers, and trainers with tools to plan and monitor machine schedules, offering full visibility into capacity, automated job tracking, and proactive notifications related to interruptions. This helps shopfloor operators see clear task assignments, while production managers maintain oversight of EOS’ operations in real-time, ensuring optimal resource allocation and minimizing potential downtime.

Solution

Forming a digital thread: the CO-AM Software Platform

“Frictionless communication between the sales and engineering teams is paramount. CO-AM allows us to annotate, capture, and communicate vital information to others within the system,” says Hayes.

EOS’ customers can also use CO-AM as a production management system and add other 3D printers, like post-processing, finishing, and QC equipment.

“The platform is great because it captures the whole manufacturing ecosystem in your production. We’ve been using it since 2019. CO-AM’s connectivity is pivotal in tracking machine availability, printer utilization, and analytics on the materials running on different systems. We also use it for ITAR builds, transferring the files separately using built-in ITAR workflows for security reasons,” says Hayes.

But what if a company is just getting started? Well, the platform scales with an organization’s infrastructure and requirements. “CO-AM is great for project tracking, and it scales consistently, no matter your organization’s complexity,” adds Hayes.

The platform streamlined EOS’ communication and improved operational visibility on past projects, allowing anyone within the company to kickstart projects if similar business opportunities arose. Ultimately, this allowed their team to meet customer expectations compared to competitors and deliver machines capable of manufacturing parts for a specific application.

“We better understand what we’re doing in each industry and for which customers. Plus, it has improved decision-making and reduced repetitive work. Now, we understand our production capacity and can prioritize machine utilization rates in our network. Most importantly, there’s no more back-and-forth email communication, as all exchanges are stored in the notes within the system.”

CO-AM’s Sales Dashboard enables EOS’ sales representatives and channel partners to efficiently create and manage customer requests, providing instant pricing and project visibility. Requests are seamlessly passed to the sales support team for commercial validation and EOS’ process engineers for technical feasibility analysis, ensuring smooth, accurate handoffs that reduce lead times and improve end customer satisfaction.

Within the system are integrated Power BI dashboards that give sales and production managers actionable insights into sales, production, and quality KPIs to further drive data-led improvements and operational excellence.

Result

Production management software capable of capturing key analytics, seamlessly connecting teams, and uncovering new opportunities

Communication mishaps are no more, thanks to CO-AM’s Machine Connectivity. The system links and manages EOS’ range of 3D printers, providing visibility on machine data, automation, and other analytics. “All our people can see real-time data across our printer network,” says Hayes.

And as CO-AM is machine and system-agnostic, it supports existing software tools within a company’s IT system, such as SAP and Salesforce. “The sales team needed one way to interface with the entire organization,” says Hayes. “They should live and work in Salesforce. At the same time, they must submit prototypes and benchmark builds from Salesforce to CO-AM, which is running in the background. We also want to look at larger customer data analytics and believe it’s possible with CO-AM.”

Looking ahead, EOS is analyzing our Pre-Print AM Software solutions for workflow scripting. Moreover, our security offerings are also being considered. “We anticipate increased customer need for secure file transfer, so Identify3D seems like a good fit. The demand from defense contractors and ITAR-regulator needs is becoming more ever-present,” adds Hayes. “Another factor is we’re looking to automate as many workflows as possible. This means the Magics SDK software is a viable option and is being reviewed internally too.”

EOS is extremely satisfied with CO-AM. So, the question is: do they see themselves going through more software audits in the future?

“No, we see ourselves using CO-AM for years to come. Initially, we tried to customize everything ourselves. But we quickly realized it wasn’t necessary when we spoke to the CO-AM team.

“We learned we could move much faster utilizing a SaaS solution. CO-AM offers standardized workflows based on best practices within the industry. These ready-made, optimized processes are aligned with accepted industry standards, enabling us to increase efficiency, improve compliance, and reduce errors within our operations,” says Hayes.

By adopting CO-AM, EOS has standardized its processes, eliminated redundant efforts across customer sites, enhanced cross-team collaboration, and positioned itself to scale effectively while delivering consistent value to its customers. It’s a cohesive software platform that creates a truly digital thread, connecting companies with clients; companies with partners; and employees and teams together.

“CO-AM is an attractive solution for customers who need production management software that’s not already integrated with super large [manufacturing execution system] MES software. It offers professionalization for companies growing into more complex manufacturing organizations,” concludes Hayes.

Share on:

This case study in a few words

Industrial

- Materialise CO-AM Software Platform

- CO-AM Production Management system

- Connected 50+ 3D printers across regions and time zones

- Streamlined internal communication and improved collaboration between departments

- Allowed for future integration with existing software platforms

- Provided operational insights, such as printer scheduling, productivity tracking, and data analytics

How we helped

Connect and streamline your AM workflows to the production floor with business systems, machine connectivity, and solutions that improve quality output and ROI.

Plan and manage the entire AM process to maximize throughput, optimize capacity, and gain complete visibility across your operations.