Material

Ultrasint TPU 90A-01

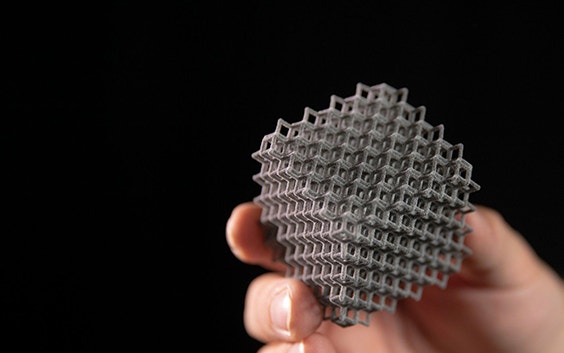

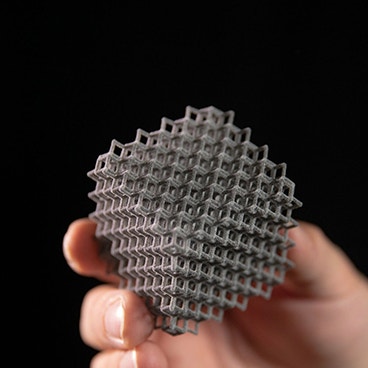

Ultrasint TPU 90A-01, a thermoplastic polyurethane, combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption. Developed for Multi Jet Fusion printers, this fully functional material has high elongation at break, excellent surface quality, and offers a high level of detail.

Technical specifications

| Maximum part dimensions | 370 x 274 x 375 mm |

| Standard accuracy | ±0.9% (XY) up to ±1.8% (Z) with lower limits on ±1 mm (XY) up to ±1.5 mm (Z) |

| Layer thickness | 0.1 mm |

| Minimum wall thickness | 1 mm |

| Minimum detail size | 0.5 mm |

| Interlocking or moving parts | Yes |

| Internal channels | Yes |

| Surface structure | Grainy structure with stone-gray color |

Datasheet

| PARAMETER | VALUE | UNIT | METHOD |

| ASTM D2240 | 1.10 | g/cm³ | |

| DIN 53504 | 9 | MPa | |

| DIN EN ISO 527 | 85 | MPa | |

| DIN EN ISO 178 | 75 | MPa | |

| DIN EN ISO 179 (Notched, Charpy) | Partial break | kJ/m² | |

| DIN 53504 | 220 | % | |

| ASTM D2240 | 88 | Shore A |

Actual values may vary with build conditions and in relation to the part’s geometry and orientation.

Please get in touch with our team for more information and guidance.

Finishing degrees

The right finish can transform your print into a product. Explore the post-production finishes we offer for this material. If you have any questions or special requests, get in touch with us.

Train and learn

Get more from your next project with helpful resources dedicated to Ultrasint TPU 90A-01 and Multi Jet Fusion.