Material

Stainless Steel (SS316L)

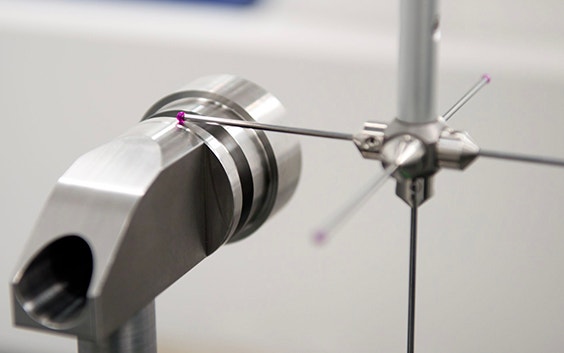

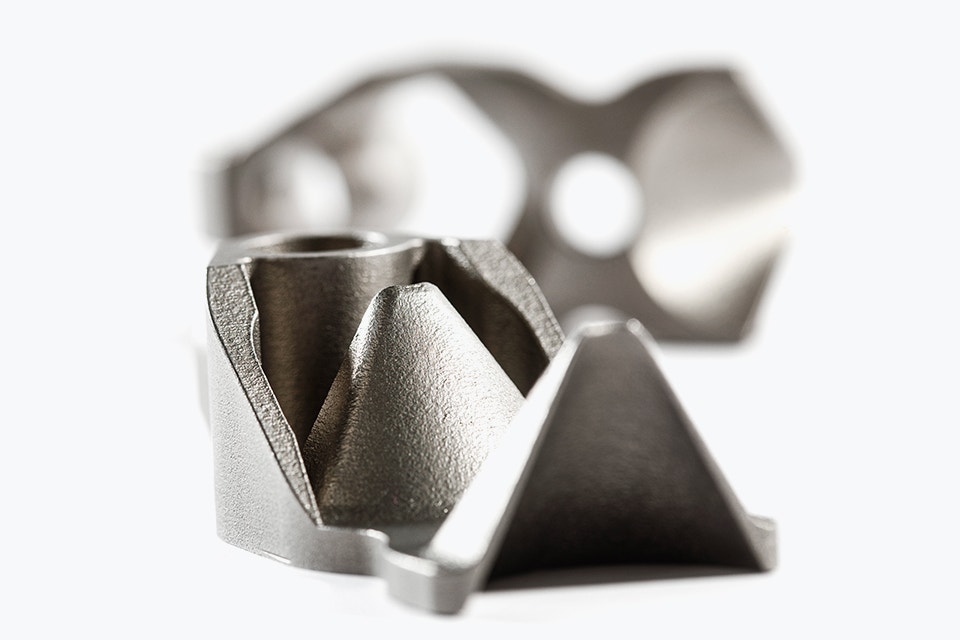

Stainless steel (SS316L) is a low-carbon nickel-chromium-molybdenum based steel alloy that combines excellent strength, high ductility, and good thermal properties. With its high resistance to corrosion and pitting, including chemical corrosion, this material is suitable for food-safe applications, wearables, machine components, and medical instruments, amongst others.

Technical specifications

| Maximum part dimensions | 250 x 250 x 305 mm |

| Standard accuracy | Better than or equal to the industry standards:

See design guidelines for more information on standard accuracy. |

| Layer thickness | Standard: 0.08 mm, Performance: 0.04 mm |

| Minimum wall thickness | Standard: 1 mm, Performance: 0.5 mm |

| Minimum detail size | 0.4 mm |

| Interlocking or moving parts | No |

| Internal channels | Yes |

| Surface structure | Rough surface |

Grades

Balance performance and efficiency in every project with your choice of Standard or Performance grades.Standard

The all-rounder, where it’s all about technology:

- Ideal for simple end-use parts

- Form-, fit-, and function-testing

- Strength and density similar to cast parts

- Industry-standard quality requirements

Performance

The specialist, for complex production:

- Ideal for complex metal parts designed for AM

- Preferred for applications in demanding environments

- Suited for series production

- Higher strength and density than casting

- Specialized quality test reports available to your specification

Datasheet

| PARAMETER | STANDARD GRADE | PERFORMANCE GRADE | STANDARD | UNIT | METHOD |

| WGE-Prod-067EN | >7.91 | g/cm³ | |||

| WGE-Prod-067EN | >99.0 | % | |||

| DIN EN ISO 6892-1:2009 | >510 | MPa | |||

| DIN EN ISO 6892-1:2009 | >300 | MPa | |||

| DIN EN ISO 6892-1:2009 | 180 | GPa | |||

| DIN EN ISO 6892-1:2009 | >45 | % | |||

| ISO 4287 / AITM 1-00070 | <20 | µm | |||

| ISO 4287 / AITM 1-00070 | <90 | µm | |||

| ISO 6597-1:03-2006 | >170 | HV |

Actual values may vary with build conditions.

Strong tensions due to part geometry may distort parts, potentially leading to greater deviation in values. Values for surface roughness depend on the orientation of the surface; downward-facing surfaces and surfaces with support will be rougher.

These values show the material characteristics with additional stress relief heat treatment. Extra heat treatment steps or aging for even higher mechanical properties may be possible, e.g. for serial-produced parts.

Please get in touch with our team for more information.

Finishing degrees

The right finish can transform your print into a product. Explore the post-production finishes we offer for this material. If you have any questions or special requests, get in touch with us.

Train and learn

Get more from your next project with helpful resources dedicated to stainless steel (SS316L) and metal 3D printing.