CASE STUDY

Titanium Inserts for Spacecraft: 66% Lighter with Metal 3D Printing

Each kilogram put into orbit costs around $20,000, meaning that every gram saved makes space a more attainable frontier. Materialise worked together with the engineering division of Atos, a global leader in digital services, to reinvent a titanium insert that is widely used in satellites with the help of 3D printing for aerospace.

Industry

Aerospace

Solutions used

Metal 3D printing

Titanium

Why this approach

Weight reduction

Design freedom

Material selection

The challenge

Reinvent a part to reduce its weight while maintaining strength

When designing or engineering a component for spacecraft structures, weight optimization is a crucial challenge — reducing weight means more useful equipment can be sent into space and results in considerable cost savings with each launch. However, weight reduction cannot be pursued at the expense of strength and performance, meaning that parts need to be designed and manufactured to meet exceedingly strict requirements.

Titanium inserts are widely used in the aerospace sector to attach devices to satellites. These inserts are often highly loaded, lifting large and heavy structures. Therefore, they need to have a high strength-to-weight ratio, i.e., have high specific strength and rigidity but minimal weight.

Classical inserts are commonly a brick-like shape of aluminum or titanium, as they are manufactured by machining. Being completely solid, they are costly to produce due to the volume of material needed and also raise the operational costs on each launch due to their weight.

Atos knew there was a better way. So, they partnered with Materialise to explore a new approach to the design and production of the inserts.

The solution

3D printing for aerospace

By choosing additive manufacturing for aerospace, Atos was able to continue using the same materials as before, i.e., aluminum and titanium, and the design freedom meant they could completely reinvent the part to reduce its weight and improve its overall performance.

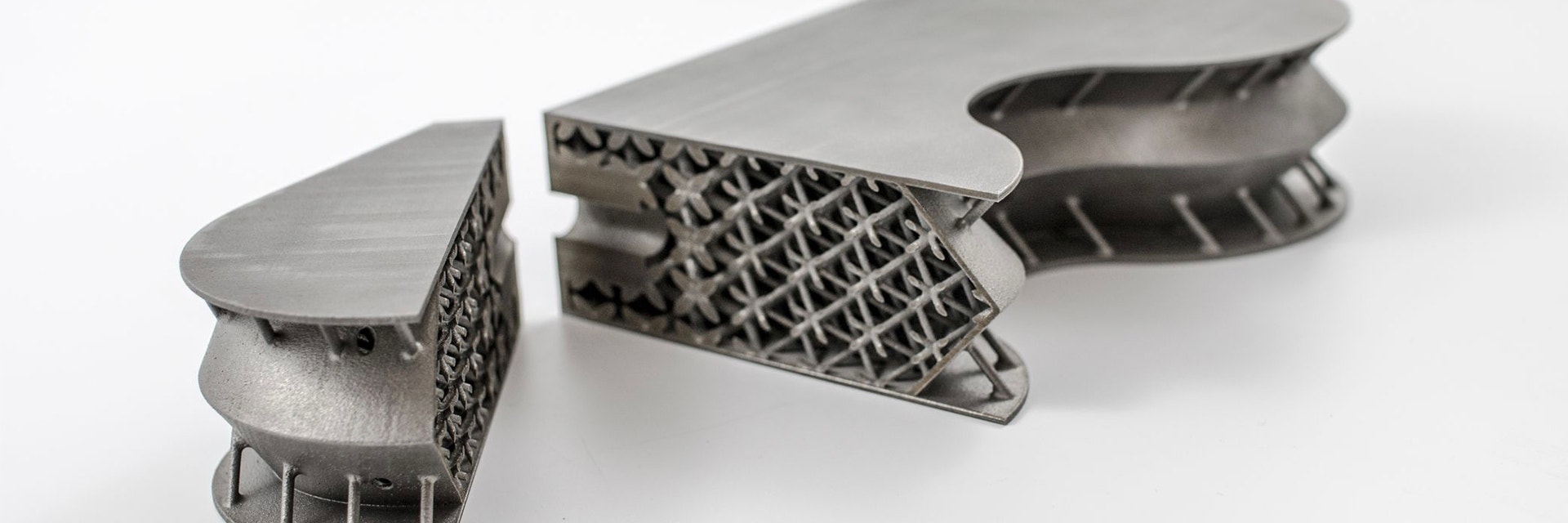

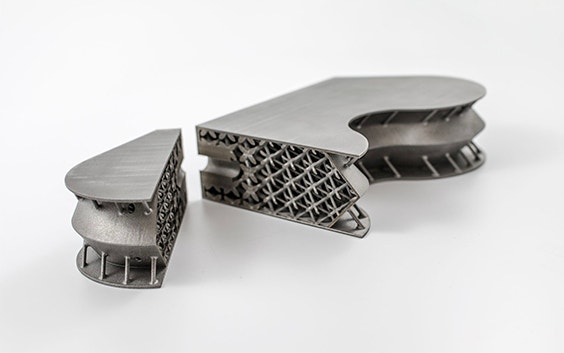

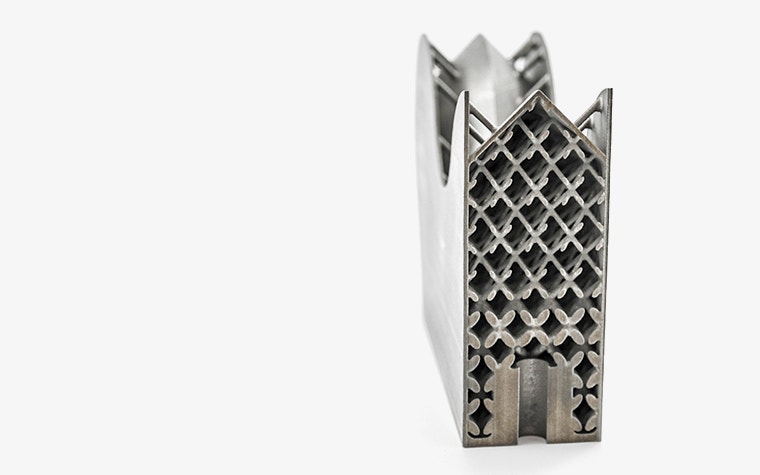

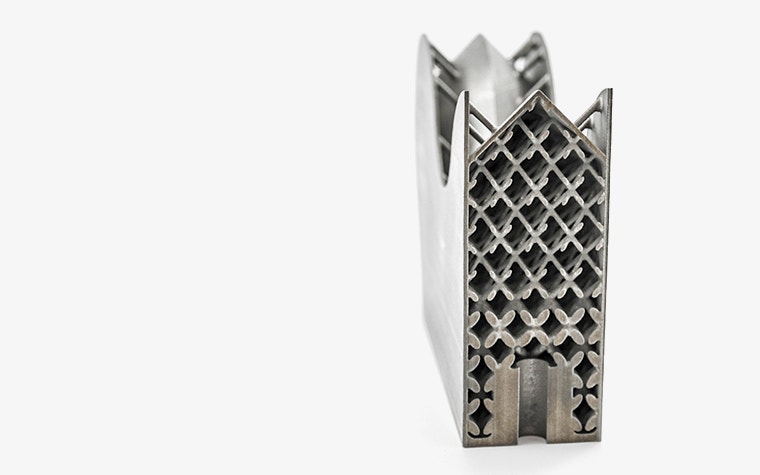

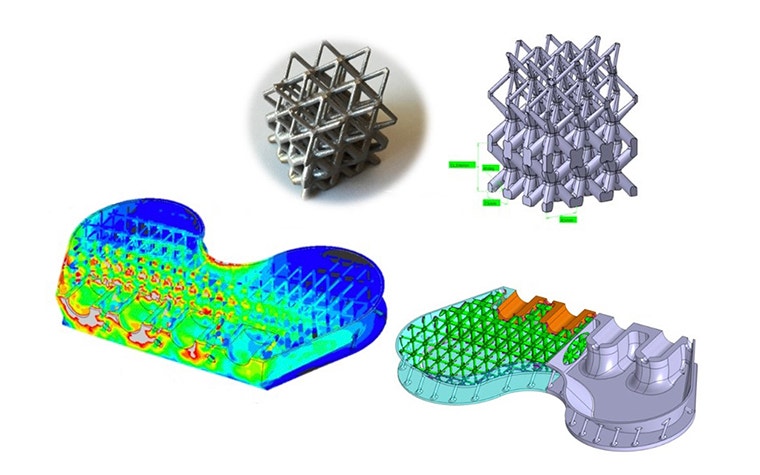

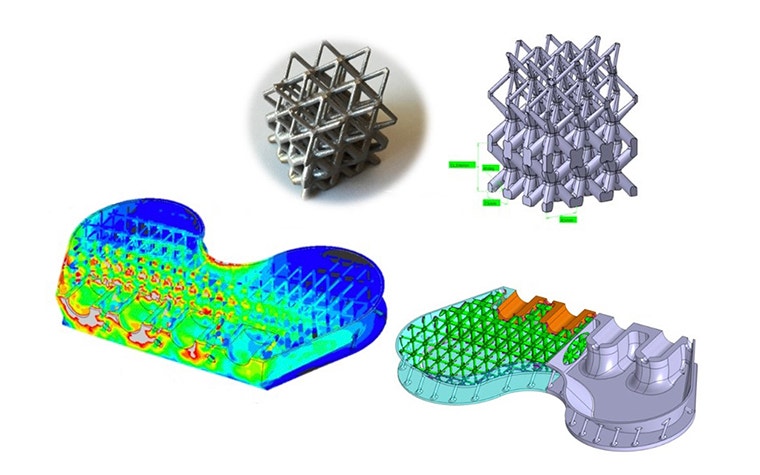

Together with engineers at Materialise, they used advanced techniques, including topology optimization and lattice structure design, to reduce the insert’s mass from 1,454 grams to 500 grams. During the process, they were also able to resolve thermo-elastic stress issues with the original design, resulting in a new design that would offer increased durability and improved load distribution.

As a certified holder of production organization approval (POA), Materialise manufactured the parts in titanium using selective laser melting (SLM) at its metal 3D printing factory in Bremen — the Metal Competence Center unites metal 3D printing software development, manufacturing, and sustainability research under one roof, supporting integrated production and development.

“The weight reduction will allow the increase of useful equipment to be used in satellites and result in considerable cost savings for each launch.”

— Marta García-Cosío, Mechanical Engineering Director, Atos Spain

The result

66% lighter, more durable, offering improved load distribution

With a cleverly optimized design produced using metal 3D printing, the new titanium inserts are just one-third of the initial weight, with some additional advantages of increased durability and improved load distribution.

In addition to the weight reduction, the team was also able to resolve thermo-elastic stress issues with the original design — as these inserts are installed during the curing process of carbon fiber-reinforced polymers, they are subject to thermo-elastic stresses. The optimized design reduces vulnerability to these stresses and improves load distribution, extending the lifetime of the inserts.

Marta García-Cosío, Mechanical Engineering Director at Atos Spain, explains, “The weight reduction will allow the increase of useful equipment to be used in satellites and result in considerable cost savings for each launch. We are proud of this innovation. By creating this complex product in such a short time, Atos and Materialise are among the top providers of metal 3D printing solutions.”

Share on: