CASE STUDY

Additive Manufacturing in Aerospace: How Stirling Dynamics Mastered the Art of Application Spotting

Stirling Dynamics is renowned for solving challenging problems using additive manufacturing (AM), with examples ranging from their unique seat blocker to the DADO panel repair kit and airplane seat repair solutions. Discover how their approach to application spotting, market evaluation, and testing paves the way to adopting 3D printing successfully.

Industry

Aerospace

Key solutions

- Certified manufacturing for aerospace

- PA-FR

- Selective laser sintering

The impact

- Fast lead times

- Customization opportunities

- No minimum order quantities

- No tooling costs

As an EASA 21.J-certified design organization, Stirling Dynamics has always excelled at finding out-of-the-box solutions for commercial aircraft, serving OEMs, MROs, and airlines. Their portfolio’s broad scope covers everything from low-criticality cabin parts to electronics and avionics, reflecting a diverse skill set and a unique approach to problem-solving.

For Henryk Bork, Head of Aviation at Stirling Dynamics, that approach begins with passion.

“Our core offering is design and certification, but the fun part comes when we start developing products. This is what you can touch and feel,” he tells us. “It’s where we can delight our customers because we are experts in niche and bespoke product design. Whenever they are unhappy with the performance, lead time, or cost of an OEM part, we love taking on the challenge of improving this — it’s what drives us.”

Using AM: Spotting the right applications

But passion can only get you so far. A key part of solving any problem is knowing which materials and technologies are right for the job, and Henryk has shown a keen sense of when and where to use 3D printing. It’s a skill that plays a crucial role in Stirling Dynamic’s success. The company takes application spotting seriously, especially when designing for aerospace, following a stringent internal process to evaluate every potential project.

“We developed this process for several reasons. Not everything becomes a 3D printing project, and we have to be very careful. Developing a part and bringing it up to an EASA Form-1 approval is a very time-consuming process for all involved,” says Henryk. “We first need to check whether 3D printing is applicable, then consider our internal policy of never copying a part.”

It’s an approach that benefits everyone from Stirling Dynamics to their customers and suppliers. Examples like the DADO panel repair kit prove that it’s more than just words — repair rather than replace. Reimagine rather than recreate.

Reimagine, not recreate

“We want to make sure we always improve the product we’re working on, which is why we begin with a root cause analysis to understand why the customer had pain with the part,” he explains. “There can be multiple reasons — it may be the lead time, but most likely, it’s performance-related, meaning breakages or cracks.”

Equally important is Stirling Dynamic’s determination to evaluate the business case behind each project. A feasibility study follows the root cause analysis, a process that Henryk says has been boosted greatly by partnerships with Materialise and Proponent.

“We’ve learned that our leads are great for building our use case catalog, but there isn't always a business case behind them. But we can leverage our relationship with Proponent, for instance, to make our certified solutions available to any operators that need them,” Henryk continues. “Finding customers with similar needs gives us a clear indication that there’s potential, there’s a pain point worth solving, there’s a niche to produce this part and bring it to a wider audience.”

A question of time

Stirling Dynamic’s seat blocker is a great example of this approach. Originally designed during the COVID-19 pandemic to help airlines cut costs by effectively removing seats from the schematics without physically removing them from the plane, the team has now repurposed it for a new market.

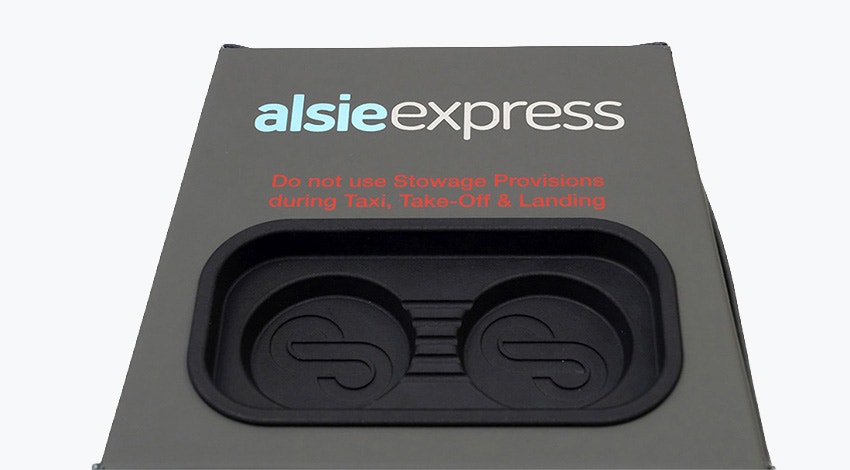

“The product's application changed when the pandemic ended. Now, our customers can offer extended comfort to their passengers by turning a row of three seats into two,” says Sergey Gettinger, Chief Design Engineer at Stirling Dynamics. “We worked on a new design, put it through the testing phase, and began manufacturing. The shape is roughly the same as the original, but we improved the inserts and the cupholders.”

The latest version has come a long way from the original in both design and aesthetics. Document pockets and detachable 3D-printed slots for chargers, devices, and cups are the most notable new features. As an EASA Part 21.G-certified holder of Production Organization Approval (POA), Materialise is certified to produce flight-ready parts like these, with a lead time of just three weeks on these particular components.

Each part is embedded into a strong foam material, ensuring the seat blocker keeps its shape while removing the risk of injury should anyone fall on it and keeping weight to a minimum — just 1.5 kg. The whole part is finished in handcrafted leather, available in various colors. Most importantly, it’s produced with Form-1 accreditation, making it officially installable on any aircraft seat.

Customization: AM’s bread and butter

“[Customization] makes 3D printing very attractive — it would be impossible to balance the tooling costs with any other method.”

This combination of 3D printing and handcrafted leather allows Stirling Dynamic’s customers plenty of room for customization — an important asset for a part that sits so prominently in the aircraft cabin.

“We can go to any customer and let them choose the color and the print of the leather,” explains Henryk. “But even better are the options for the inserts. They can choose whether they’re separated or combined to allow space for a mobile phone, for example, or have their logo integrated into the design. That makes 3D printing very attractive — it would be impossible to balance the tooling costs with any other method.

“There are no other options if we wanted to bring this part to market because the costs are reasonable for the recurring part. Otherwise, we would need a minimum order quantity, and that’s very difficult when you start within a niche.”

Involving the customer

While the seat blocker is the latest in a long line of products that showcase Stirling Dynamics’s problem-solving and creativity, it’s the approach behind it that is truly worth noting. Their complete process is an example to companies wondering how to adopt 3D printing successfully, and it doesn’t end with production. Once the part is ready, they bring their customers into the equation through a three-stage trial process that improves quality, builds trust, and helps gather valuable data for the industry. It's particularly beneficial when dealing with the relative unknown of using 3D-printed parts for certain applications.

“Our offer to the customer is always balanced on three stages of feedback and improvement,” explains Henryk. “We send prototypes to make sure fit, form, and function are guaranteed and meet their expectations. Because it’s 3D-printed, we can easily adapt whatever needs adapting and do another loop, then agree on a trial period of one to three months. That trial series provides us both with information we don’t have: how will it handle fatigue and in-service performance, such as yellowing from exposure to sunlight, for example? We’ll go through all of that before we finalize the part, taking away some of the risk of adopting a newer technology like this.”

What comes next?

Stirling Dynamic’s unique approach to problem-solving, knowledge of when and how to use 3D printing, and their all-important certifications have helped deliver multiple low-criticality parts for commercial airlines. Their solutions are proven for applications like repairs, spare parts, and in-cabin items. But what do they see as the future of 3D printing in aerospace?

“We are very much looking forward to collaborating with Materialise on metal printing for aerospace as well. It will be another game changer, and I have no lack of imagination,” Henryk answers. “It could be very interesting in terms of structural repairs and different solutions that don’t exist yet. Make no mistake, this requires time, research, development, and budget — but with Materialise and Proponent, we have the right partners to make it happen."

Share on: