CASE STUDY

More Data, Improved Decision-Making: CO-AM Brings Efficiency and Transparency to Parts on Demand

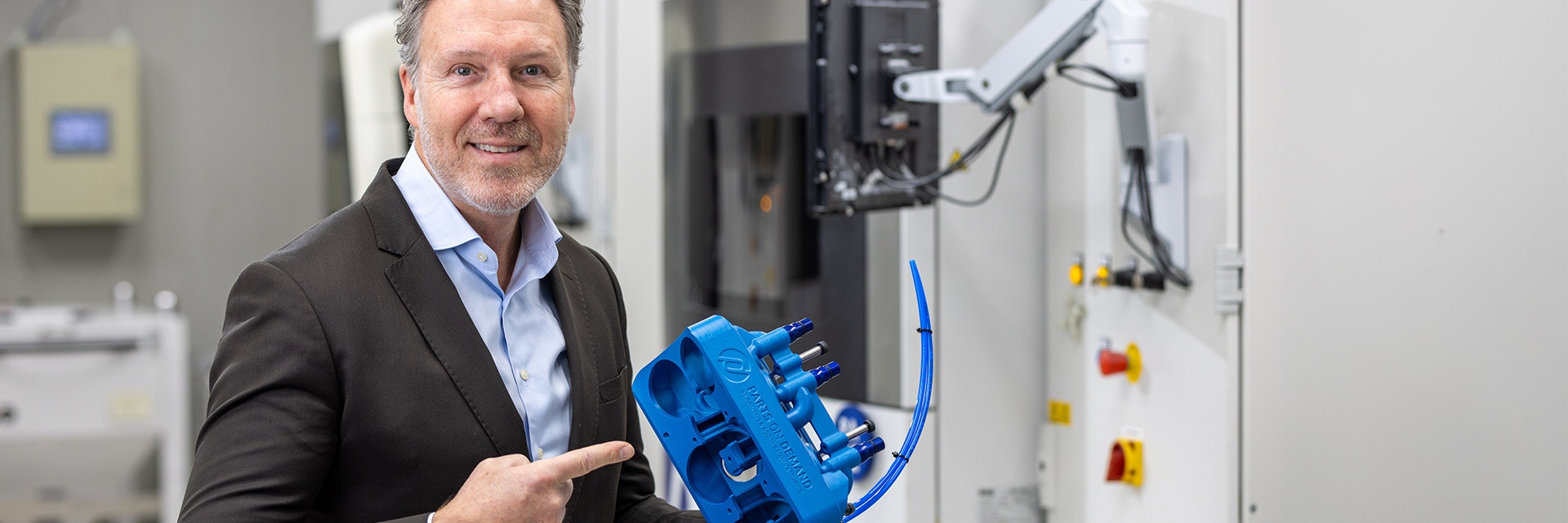

The Netherlands-based 3D printing provider promises its customers a smarter, better, more efficient way to create end-use parts — and that begins internally. For long-time Magics user and self-proclaimed Geek-in-Chief Neil van Es, the Materialise CO-AM Software Platform is the ideal tool to ensure his company delivers on its word.

Industry

Industrial 3D printing

Key solutions

- Materialise Magics

- Materialise CO-AM MES, OMS, and Customer Portal

- Magics SDK

- Power BI

The impact

- A centralized, scalable platform

- Improve communication and transparency

- Empower part tracking throughout production

- Enable automation in production workflows

- Integration between Materialise Magics and MES

The challenge

Tackle hidden inefficiencies and complexity. Rethink the existing software stack.

Selective laser sintering has always been the technology of choice for Parts on Demand. It’s an essential tool in delivering on the company’s mission: create more parts better, faster, and more efficiently. By leveraging 3D printing's aptitude for complexity and ability to produce quality end-use parts locally, they help customers spend less time on assembly and adapt quickly to market changes.

Scaling up is hard to do

Naturally, living up to that promise isn’t always easy, especially as the company has scaled considerably since its birth in 2011. A steady uptick in both the number and complexity of parts led to several challenges: assessing part printability for a large number of requests, production scheduling, and ensuring the right post-processing steps take place in the right order to deliver a part that meets customer expectations, to name a few.

“Firstly, the difficulty with producing such complex parts is reviewing them all to ensure they meet our design and production criteria,” explains Neil van Es, Founder (or self-proclaimed ‘Geek-in-Chief’) of Parts on Demand. “We have many smaller customers — we want to give them all the proper advice, but it’s inherently more difficult to put adequate effort into reviewing those requests.”

The importance of transparency

A second challenge — knowing exactly where a particular part is in its production process — stemmed from shortcomings in the company’s previous software. Transparency was limited, internal communication occurred face-to-face, and managing a range of individual software tools was becoming increasingly complicated.

“We developed certain tools and middleware for a while, but over time, we ended up with so many different things that it was hard to not only maintain them all but also add functionality,” Neil continues. “I knew we needed to rethink our software stack because we couldn’t maintain it for years to come, and it was leading to frustrations when tracking parts. Everyone asked the production team for updates, but that information should be visible in the system — you shouldn’t have to ask a colleague to see where certain parts are in the process.”

To Neil and his team, the answer to these challenges was simple: find a centralized, scalable software platform that enabled transparency, efficiency, and automation throughout their operations.

“Every 3D printing company has different processes. There is no one-size-fits-all. Though we believe that it is best to try and adopt a standard solution and keep the customization to a bare minimum,” explains Neil. “We want to benefit from new features, and that requires sticking to a standard, yet highly configurable, software.”

Having trusted Materialise Magics as their build prep software of choice from the get-go, the Materialise CO-AM Software Platform was a natural contender.

The solution

Automating workflows and enhancing transparency with CO-AM and Magics

While introducing any new software requires careful change management, Materialise’s onboarding process was designed to ensure a smooth transition for the Parts on Demand team. Neil also placed a strong emphasis on integrating employee feedback — a valuable opportunity for the users to experience CO-AM’s benefits firsthand. He recognized the importance of involving the team early and addressing any pain points they had with the previous software.

“We are working hard during the integration phase [with our ERP and CRM system Odoo] to involve them and incorporate their feedback, which really helps with getting them up and running,” Neil explains. While he acknowledges that there may be challenges as the team adjusts, he is confident that CO-AM’s capabilities, paired with its high configurability and Materialise’s engagement, will minimize disruptions.

Seamless integration with Materialise Magics

Understandably, one of CO-AM’s biggest selling points was its seamless connection to Materialise Magics — software that Neil described as the backbone of his factory and one his team knows well. It allowed them to simplify and streamline their existing workflows. In the previous system, the team would have needed to work on a local Windows folder structure with the downloaded STL, save the build jobs, and manually adjust actual quantities for each build back in the MES.

“The guys in build prep can just grab parts from CO-AM and open them automatically in the build in Magics, nest the build, and save it back into CO-AM,” Neil explains. “Before, there was a lot of back-and-forth administration, which often led to human error. Now, it’s seamless.”

The benefits didn’t stop at build preparation, however; automating production processes had a big impact, especially when it came to managing the diverse range of parts the team handles. Previously, only 60% of their parts followed a predefined workflow. The remaining 40% involved minor deviations to the process, and these weren’t documented — it was hard to keep track, and managing these parts required a lot of manual labor. Thanks to CO-AM, every part now follows a set work plan, allowing the team to track it throughout the entire process.

Configurability and data

This is all made possible by CO-AM’s granular configurability, which allows for a true digital twin — an important characteristic, especially when it comes to cost. Parts on Demand can rely on standard yet highly configurable software without investing heavily in customized development, all while gaining valuable insights for every build.

By closely monitoring production, CO-AM automatically gathers important production data. The software tracks precisely when a part succeeds or fails during the process. In the latter case, it can also specify the defect and reason for failure, and if these errors reoccur, the team can use that data to plan corrective and preventive actions. The auditability of customer and production-related data is entirely covered in a single system.

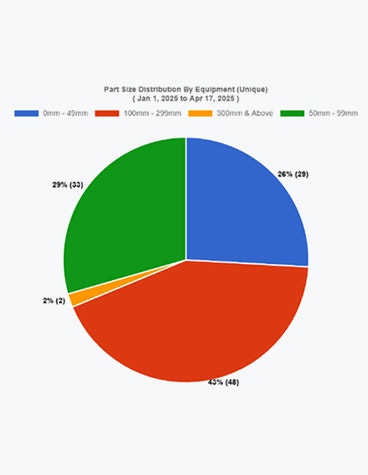

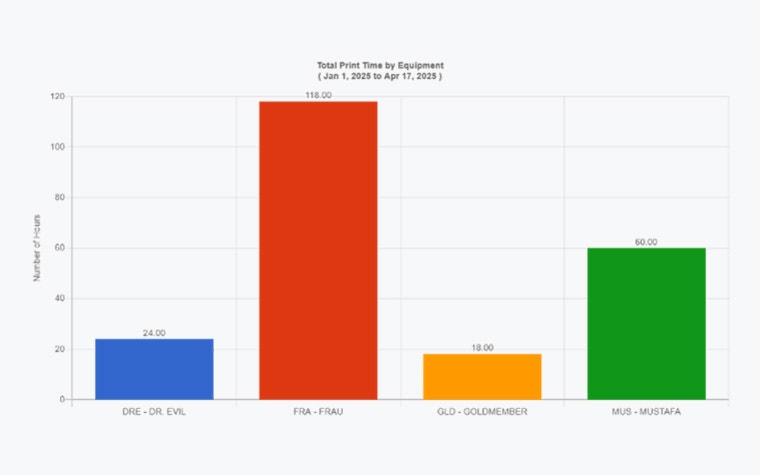

Data, like print time and part size, is easily tracked. Groovy, baby.

For day-to-day operations, Parts on Demand can navigate through a set of pre-configured dashboards displaying key KPIs. For more complex data mining, including root-cause analysis, identification of bottlenecks, and turnaround time per customer, Parts on Demand has full access to their data and can dig through it with commercially available Business Intelligence tools such as Power BI.

Automating tasks with Materialise Magics Software Development Kit (SDK)

Another benefit of CO-AM is its integration with the powerful Magics SDK, enabling Parts on Demand to automate complex tasks on 3D geometries and lay the groundwork for future innovation. Aside from automatically highlighting parts requiring a defined orientation, detecting poor mesh and material-dependent thin walls, and automating file modifications, it helps consistently capture the key metrics that put production at risk and define the cost per part.

“One of the main reasons we decided to go with CO-AM is that it gives us access to the entire SDK from the command line,” Neil notes. “We’ve started by automating a basic set of features, but we can do really fancy stuff in the future that we could not do with any other system because it wouldn't allow us to leverage their functions.”

The result

Boosted efficiency, reduced errors, and scalable production

Parts on Demand is already seeing the benefits of implementing CO-AM, particularly when it comes to automating tasks and eliminating human error and variability. The latter is particularly valuable when customers demand short lead times.

“The real value comes from eliminating the risk of failure and documenting the whole process — the time savings really kick in when you prevent a project from going wrong,” explains Neil. “Imagine you print a part in the wrong orientation, but it gets shipped out to the customer anyway. You need to print it and ship it out again — that would cost us one-and-a-half weeks.”

It's a valid example; once upon a time, whenever a customer specified an orientation for their parts, somebody would print an image of the part with the build direction and hand it to the build prepper. With CO-AM, the details are locked in the system.

Improving communication and transparency

CO-AM is also expected to have a significant impact on Parts on Demand’s communication and production management. Neil explains that addressing communication challenges, both with customers and within the team, was a priority:

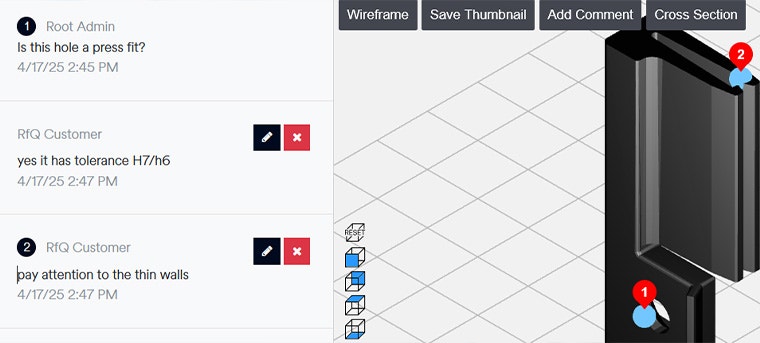

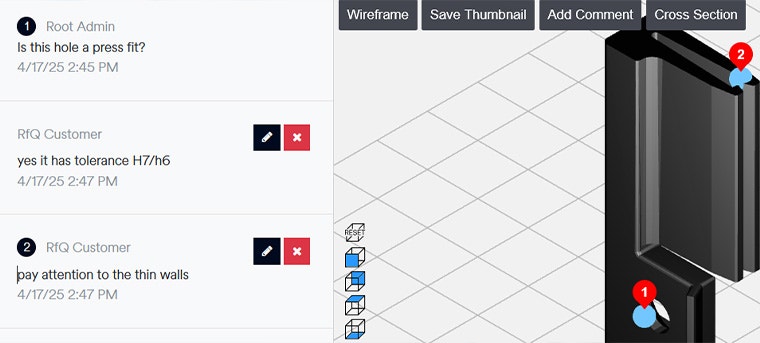

“We really wanted to have the customer-facing portal there. A lot of our current pain is communicating with customers about problems in their designs and what we need to change in manufacturing. CO-AM allows us to open up to external customers. The tools in the platform will give us a smoother front end of the process and smoother communication with the customers: what needs to be done, what we can do, what we can't do, and how the parts are getting along in production. An image speaks more than 1,000 words, and the annotation of a 3D geometry by the customer, our sales team, or any other production team member is invaluable.”

This improved transparency extends beyond customer interactions to internal workflows. Neil continues:

“The last part is also valuable internally. Colleagues will know which orders to keep an eye on, check where they are in production, and generate statistics that identify any failure points in the process and what we can do to mitigate them. It should lead to less waste and a more efficient, environmentally-friendly process.”

Likewise, Neil expects the improved transparency and efficiency that CO-AM delivers to have a positive impact on customer satisfaction. Meeting expectations — and delivering on his company’s promise — is easier when the company has a clearer overview of every project, allowing the team to find solutions early on should one become sidetracked. It could be as simple as picking up the phone. After all, the best way to solve even the smallest of problems is by proactively talking to the customer.

“Every customer has different expectations and demands. Before CO-AM, we had certain parameters we could tweak, but those expectations might still have been different from what we could offer,” he continues. “Now, we have a lot more fine-grained control over the process, and the guys on the shop floor just need to follow it. I expect it to be easier for us to meet customer expectations because we can adjust that process directly in CO-AM instead of having to do it manually in a parallel system.”

Scaling up is... not so hard to do

This extra control is positive news for the company’s future. Where once scaling up in both quantities and complexity brought new challenges, Parts on Demand is now equipped to deal with whatever comes their way.

“There are two types of complexity,” Neil tells us. “Customers could print a more complex geometry, making it harder to clean the powder, for example. Material applications are complex on a different level. It might be simple to produce 100 similar items, but if you produce 10,000, you’re always going to encounter outliers. The question then is, how do you mitigate those outliers and ensure they don’t make it to market? In either scenario, CO-AM gives us the tools we need to better manage those requirements.”

An exciting future

After bringing CO-AM on board, thoughts are already turning to the future — what would Neil like to see next? Unsurprisingly, his answer doesn’t stray far from making life easier for his team and his customers by avoiding unexpected scenarios.

“What I would really like to work on together is a machine learning layer on top of CO-AM to start training models, spot trends, and analyze things that we can’t figure out ourselves,” he tells us. “It would share that information with the customer and be more proactive in the software itself, raising alerts on projects where we’re not on track to meet a deadline, for example.”

“It has potential on the front end, too, as a sales tool. We could upload and analyze parts, mitigate some potential production hazards or risks, and take action based on that in an automated manner instead of relying on human interpretation.”

An eye on sustainability

In the not-so-distant future, Neil is also hoping that the introduction of CO-AM will help reduce current scrap rates of 5 – 10%, further bolstering sustainability efforts that include drastically reducing the CO2 footprint of their SLS powders.

“This year and last year, we focused on the big ticket items like energy reduction, producing materials with reduced carbon emissions, and reducing waste from our blasting processes,” says Neil. “The next step is to dial in our processes better to reduce waste there — I’m confident CO-AM will make a big difference.”

It’s definitely a situation we’ll follow up on in the near future, so keep an eye out for our next conversation with Parts on Demand if you’d like to know more about the impact of CO-AM on an industrial 3D printing factory.

Featured products and services

Connect and streamline your AM workflows to the production floor with business systems, machine connectivity, and solutions that improve quality output and ROI.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Share on: