CASE STUDY

How CO-AM Optimized Project Management Efficiency and Team Communications at Carpenter Additive

Serving the automotive, aerospace, and energy industries, Carpenter Additive required a solution that could handle complex and disparate information across different sources and departments. That's why the team chose our CO-AM Software Platform to help optimize project management efficiency and communications throughout its production workflow.

The challenge

Manage a large number of customer requests and projects across departments

Supplying the world with specialty alloys for over 130 years, Carpenter Technology has earned its reputation as a premier specialty materials manufacturer. However, to meet the developing needs of its customers, Carpenter decided to innovate and create a company dedicated to metal additive manufacturing (AM) in 2019: Carpenter Additive.

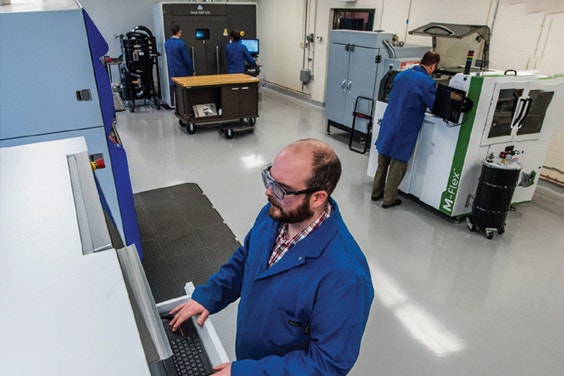

Carpenter Additive’s team of world-class metallurgists and AM experts support their customers with end-to-end metal AM solutions. These include specialty alloy atomization, powder lifecycle management solutions, and overall manufacturing services focused on material data generation and qualification to help customers accelerate AM applications. With a wide set of capabilities under one roof — from powder production to hot isostatic pressing (HIP) and heat treatment — Carpenter Additive faced an impending challenge: data consolidation.

“We have a mixture of R&D requests, as well as customer requests coming in to support our material development. It’s been tricky for us in the past to make sure that data is gathered in a convenient way and set up workflows consistent with that,” says William Herbert, Director of Technology and R&D at Carpenter Additive.

“The challenge was managing many variable requests and project inputs across the whole team, from the people on the shop floor to project managers."

The solution

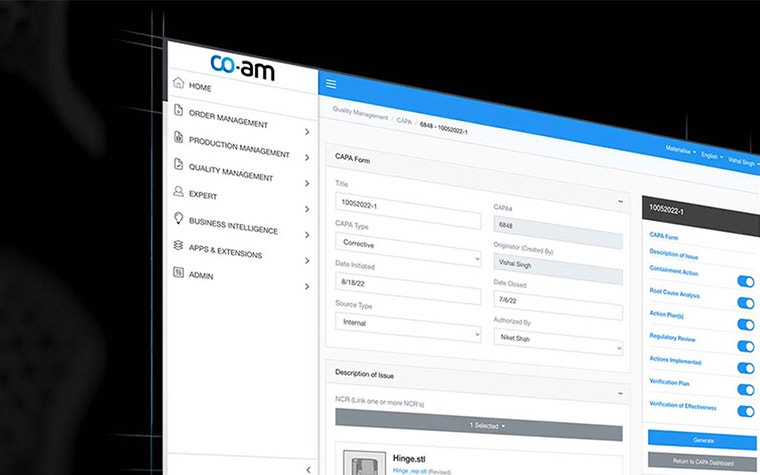

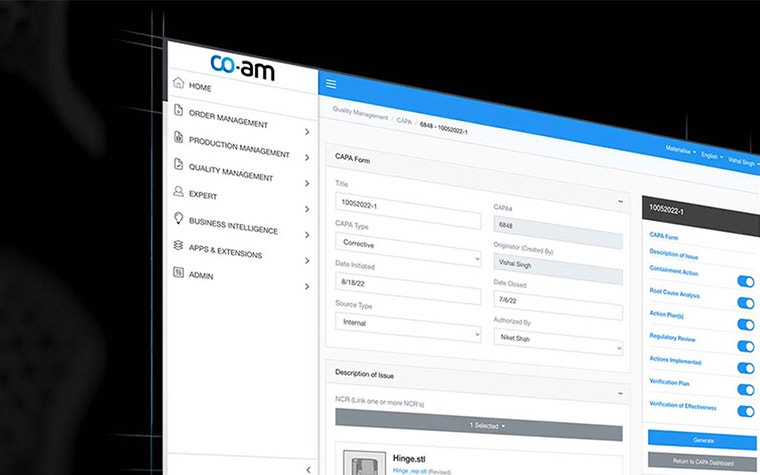

CO-AM creates a strong software backbone for a centralized digital thread

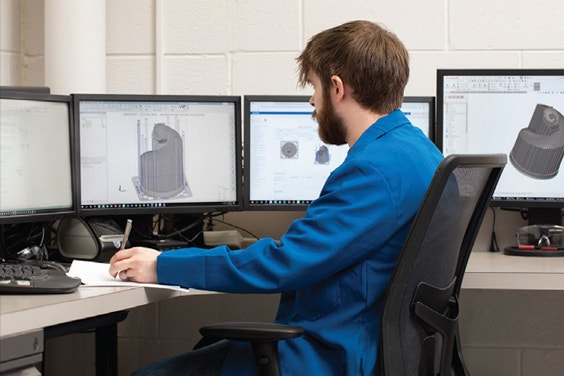

Carpenter Additive integrated CO-AM into their daily workflow, creating a strong software backbone based on a centralized digital thread. This digital thread aggregates information from builds, scheduling, and jobs to streamline operations through a centralized information hub. “CO-AM gives management and our commercial team a tool to keep tabs on work order progress without ever having to micromanage,” states William.

"One thing that was impressive and really impactful was the ability for any of us to log on from anywhere and understand the latest project status. We no longer need to ask someone or call a colleague for information. Now, we can just log on and see all the moving pieces. This was especially helpful during 2020 when the pandemic forced most of our team to work from home.”

Machine operators also began using tablets to work with CO-AM on the shop floor. “Operators now follow work instructions on tablets compared to pieces of paper that have to travel through the shop, resulting in analog data (and lots of handwritten sheets),” says William. In an industry like AM, where every build can be different, clear work instructions are paramount.

The result

A connected, centralized data hub to improve operations

By creating a connected, centralized data hub with CO-AM, the Carpenter Additive team improved their first-print quality by 14% and productivity in their manufacturing department by 22%. Plus, the organization improved efficiency in terms of project management, saving around 12 hours per week.

“I think every manufacturing company will have to adopt digital transformation or be left in the dust. For Carpenter, a 130-year-old specialty metals manufacturer, AM is a new area that can be a trailblazer for digitally enabled manufacturing and workflows. Implementing CO-AM in our group shows what’s possible when enabling a digital thread-type approach,” states William.

Utilizing CO-AM helped Carpenter enter the age of connected digital manufacturing in their AM production — improving efficiency and communication while building on an illustrious history. Imagine how CO-AM could make a difference and transform your production...

Share on:

This case study in a few words

Metal additive manufacturing

CO-AM Software Platform

- Establish a centralized data hub

- Improve efficiency and communication across teams and departments

- Manage and streamline huge amounts of data