EXPERT INSIGHT

3 Ways to Ramp up Production Risk-Free as Lockdowns Lift

Corona-related restrictions are beginning to lift in some countries, which means that many are looking at ways of ramping up production. However, business is different today than it was just a few months ago before lockdowns started. Though you might face smaller budgets, uncertain demand, and tighter resources, it’s not the time to put development plans on hold. Instead, it’s a moment to rethink the way you’ve done business in the past and move forward with a new approach that minimizes risk.

No matter where you are in the process of getting your business on track, there’s a good chance 3D printing could make sense for you. In this third and final blog in our series on getting back to business, we explore how to test market readiness, check feasibility, and even go to full-scale production itself. In the first installation of the series, we showed how 3D-printed parts can help keep employees healthy when going back to the office. Our second piece looked specifically at the benefits of rapid prototyping.

Read further to discover how 3D printing as a manufacturing technology could help you rethink what’s possible and ramp up production.

1. Test market readiness with bridge series

Grow your supply along with your demand with 3D printing. After validating your prototype and before going to full-scale production, 3D printing can help in the transition step by being the go-to for bridge series.

While you may be familiar with the benefits of 3D printing for prototyping, you may not know the advantages the technology brings for end-use products. Serial production requires quality, reliability, and repeatability. In essence, it relies on certified manufacturing.

You can rely on the support of our experts to make sure your products meet your standards by your deadline. Our in-house production, three decades of experience, ISO certifications, and industry-leading software lay the groundwork for our certified manufacturing process. Throughout the process, we work with our customers by aligning with the specific quality, safety, and reliability standards that are inherent to their business to help them reach their goals.

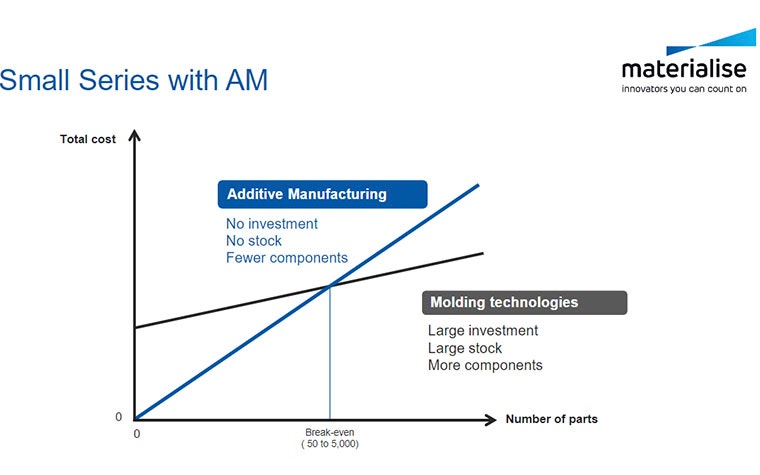

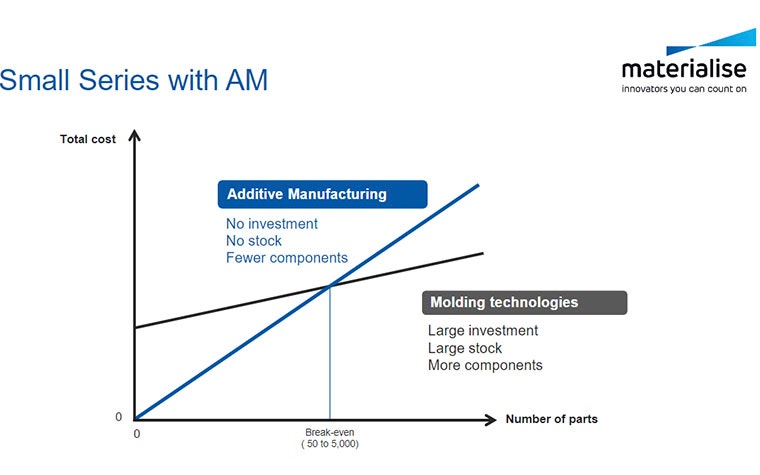

Once you have your bridge series in hand, you can see whether your product resonates with the market now. There are already many domains in your company that require investments. However, with reduced economic activity due to the coronavirus pandemic, many companies are more cost-conscious this year compared to 2019.

The good news is that decreased budgets do not mean you need to delay innovation. Bridge manufacturing using 3D printing can drastically minimize the risk by doing consumer testing, product functionality, and quality. To meet these three objectives, you would only need to manufacture a small series, which would allow you to adjust your product to ever-changing market needs. All without having to invest in expensive molds or tooling, which may become irrelevant later as your product further develops.

Many are already doing so. Take, for example, Iristick’s smart safety glasses. Operators and inspectors can use the smart safety glasses to stream video in real time to colleagues to record and share vital information, or call up technical data online. Thanks to the benefits of 3D printing, innovation company Achilles Design was able to get Iristick into small-series manufacturing at least six months ahead of schedule compared to traditional technologies. But the benefits did not stop there: they could also reduce initial investment costs, and go to market with an agile offering tailorable to customer requirements.

2. Check feasibility with Materialise Mindware

Early users’ responses can feed into a larger feasibility study on market tendencies. The goal here is to assess capital expenditure commitments, ultimately allowing for more reliable information in the decision-making process.

This analysis will help determine the sales likelihood, which could then dictate manufacturing requirements. As our Chief Technology Officer, Bart Van der Schueren, argues in this webinar, quick wins may be tempting during tough economic times but they come at a strategic cost. A smart use of AM can shed new light on product development and market introduction of new products without the need for capital expenditure commitments. Using AM in a smart way means capex can be postponed until there is a clear view on market acceptance of an in-development product. The result is a hugely valuable de-risking exercise for the capex.

Mindware, Materialise’s advisory service, is here to help you validate your business case. With our experts, you will work together to answer tough questions such as: We have an application, now how do we test it for AM desirability, viability and feasibility? How can I get reliable facts and figures to back my AM business case?

Through partnership with Mindware, real innovation is possible through new business models with minimal risk. Take Yuniku by Hoya. They disrupted the entire eyewear industry through mass customization. After taking a scan of a customer’s face, they are able to design a pair of glasses tailored to that individual, for a fit unavailable on the market until that point. 3D printing then allows the company to order the customized print, meaning there is no need for excess stock as each is made-to-order. Plus, they did not need to invest in expensive machines as a partnership with Materialise means they have access to the largest additive manufacturing factory in Europe and many other machine parks around the world.

3. Scale up production

3D printing does not end at the market research phase. It is becoming more useful than ever for full-scale production.

The benefits of 3D printing for series are relevant during uncertain economic times, when scaling up with traditional technologies could mean lots of excess stock, expensive equipment investments, and even more expensive in some cases.

Philips began to notice that their lightbulb factory required costly and frequent maintenance for a robotic gripper, a cost which they eliminated by a smart use of 3D printing. They sought to automate this process by enhancing the suction capability of the gripper and making it lighter. However, they needed a part sturdy enough to withstand the strains and stresses of high-volume “pick and place” robotic movement.

Working together, Materialise and Philips created a gripper with as few separate parts as necessary. Curved internal channels increased the part’s strength, and lightweight-but-durable aluminum proved to be the best material for the job. Now, Philips has a better part, and is increasing production volume. To top it off, their cost-savings add up to €89,000 per year.

If your production grows even more, 3D printing is a high-value option for large-scale production. For example, GE Aviation has invested in their own 3D printing facility, and uses it to print fuel nozzles and turbines. The reasons they opted for 3D printing were to create pieces at a high quality to pass the rigorous standards of the aerospace sector, while being able to keep the freedom of design necessary for these pieces.

For the turbines alone, Avio Aero, a GE Aviation company, is estimating to make 60,000 between 2022-2023. From design to production and finishing, every step of the process must be optimized and integrated to enable this seamless and efficient digital production set up. To meet this challenge head-on, Avio Aero relies on Materialise’s robust and integrated AM software solution called Streamics, which allows them to scale their 3D printing business efficiently, reliably, productively, and securely.

Get started today

Throughout this blog series, we’ve explored getting back to business as lockdowns are lifting. We’ve explored ways to keep your personnel safe, get back to product design with rapid prototyping, and ramp up production. Now it’s time to put them in action and discover first-hand what 3D printing could do for your business.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.