EXPERT INSIGHT

5 Ways Rapid Prototyping Gets Businesses Back on Track

Returning to the office as lockdowns lift first and foremost means keeping your team healthy. Once a concrete safety plan is in place, the next step is to pick up where you left off and bring operations back up to speed. In this second post of our back-to-the-office blog series, we’re sharing how 3D printing can be a major player in quickly getting your business back on track.

Due to the coronavirus, changes to the way we worked were sudden. But thanks to the capabilities of rapid prototyping and 3D printing more broadly, your product development timeframe doesn’t need to suffer. Here’s how.

1. Short lead times

When it comes to product development, time is of the essence: especially if you’ve had to put design iterations on hold during the lockdown. Iteration rounds when traditionally manufacturing prototypes are typically time-consuming processes, but this is not the case with AM.

Improving parts with 3D printing is quick and simple. Redesigning a part using traditional methods means recreating the mold to build an updated prototype from, which ultimately takes weeks or even months. Alternatively, in less than a day, those using AM can edit their original design file and send it to be 3D printed. Engineers can worry less about the time required to perfect a final design when data can be quickly updated and shared with manufacturers digitally. Once a file is sent, the prototype will be in the designer’s hands within days.

2. Cost-efficient models

One side effect of the coronavirus outbreak is the necessity for businesses to cut back on costs. The global economy has slowed, and many have faced the difficulties of decreased revenue. However, a lowered budget doesn’t have to mean delaying company innovation.

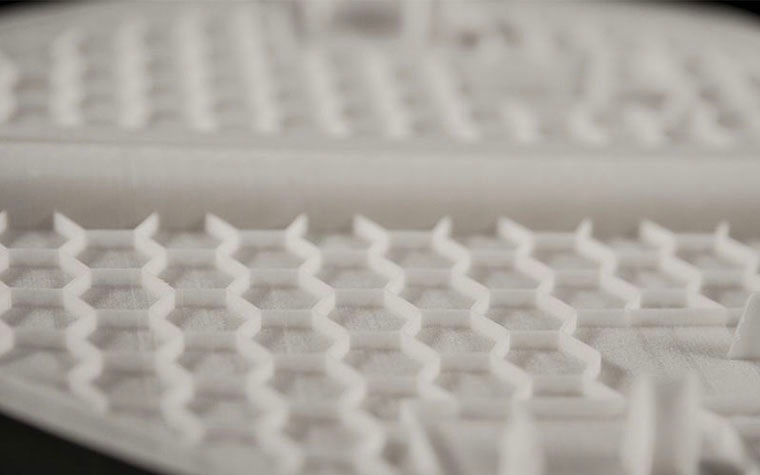

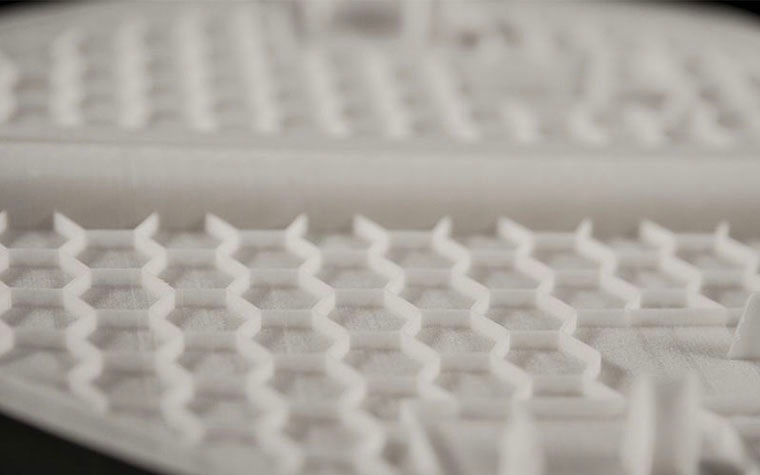

3D printing enables innovation with its freedom of design. Engineers can design parts with geometries and interlocking features that traditional manufacturing cannot — an opportunity that often means optimizing parts to reduce costs. From hollowing to incorporating lattice structures, engineers can design lightweight parts that save them 50% or more on part costs. Freedom of design delivers new possibilities that not only provide new ways to solve problems, but also save costs in a time when it’s a common demand.

3. Wide offerings

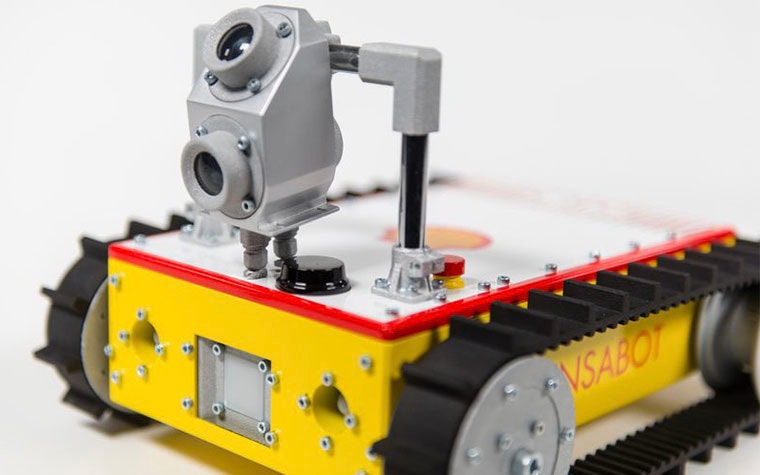

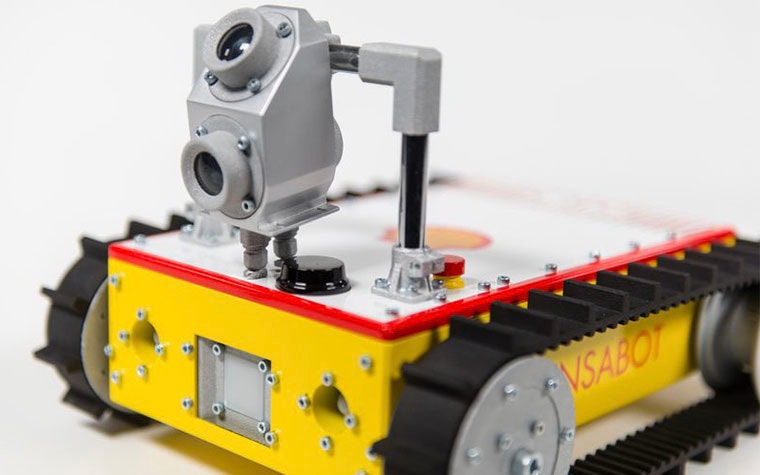

AM offers hugely varied combinations of technologies and materials that engineers can choose from to optimize their designs. From Laser Sintering to Fused Deposition Modeling and from aluminum to PA 12, there are options available to fit every project — even in the most demanding industries.

An effective prototype is one that can give product developers an accurate idea of how the final product will perform. Whether that’s reviewing the texture and color or putting the part up to rigorous testing, engineers need a prototype that’s up to the task. 3D printing offers materials that are made to withstand taxing form, fit, and function tests so engineers can have full confidence in their final design.

4. Reliable support

Services that you can be certain of in this time of uncertainty are crucial. The entire world is dealing with the impact of COVID-19, so we must support one another to bring back confidence in our economy. Having manufacturing support nearby means working with others who are familiar with your current regional situation and can quickly assist you. Our offices all over the world provide this quick and reliable local support to ensure that each customer gets the assistance they need. Our prototyping experts speak your language to help make your next product the best it can be.

5. Online services

The arrival of the coronavirus pandemic has also brought on the increased use of online services and abnormal working hours as employees juggle working from home with unanticipated responsibilities such as homeschooling. Our 24/7 online 3D printing platform provides flexible services so that as companies return to work, and employees likely continue with irregular schedules, the creation of designs can continue smoothly.

To show our support, we’re giving our customers a product from our range of 3D-printed solutions that stop the spread of germs as companies return to their offices. While supplies last, OnSite customers will receive a hooked badge holder with each order as of May 4th.*

Stay tuned

Our tips for a successful return to the office don’t stop here. Check back in next week to discover how 3D printing enables businesses to ramp up production safely during this time.

*This offer is no longer valid

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.