INTERVIEW

Meet the Users of Materialise Magics: Zenith Tecnica

Our Materialise Magics users are much more than just customers — they’re key partners. To highlight that, we’ll be sitting down with some of these AM champions who have been with us from the very beginning to find out why they chose to work with this software, how it helps them achieve their goals, and what they hope to see in the future.

Founded in 2014, Zenith Tecnica is a New Zealand-based contract manufacturer that specializes in titanium 3D printing. Just seven years on, and they can definitely be considered leaders in their field. Seeing such incredible growth in such a short space of time made us very excited to talk to the team about the role that Materialise Magics has played in their journey so far.

We spoke with Production Lead, Kurt Schmidt, and learned some fascinating insights.

How did you first encounter Materialise?

The Magics software came with our first GE additive machine in 2014. This originally came in as an Arcam Q10 machine, and then we later upgraded it to a Q10plus machine. What’s quite interesting about that machine is that it has one of the largest running hours out of any Q-series machine in the world, and we’ve been running everything on it through Materialise software. So, we may have stacked up the most Materialise Magics hours out of any Arcam user in the world!

Why did you choose Materialise software solutions?

There’s been a few trials (of other software) that didn’t quite compare to the user interface of Magics or the capability of fixing parts — Magics is just really incredible at that. And then there are just a lot of other tools that Magics has that just were not found in any other software package.

We were also very impressed with the customer support. The Materialise teams in Malaysia and Belgium provide great support, give fast feedback, and push to try and make the product better for us.

How has your machine park and software usage evolved over time?

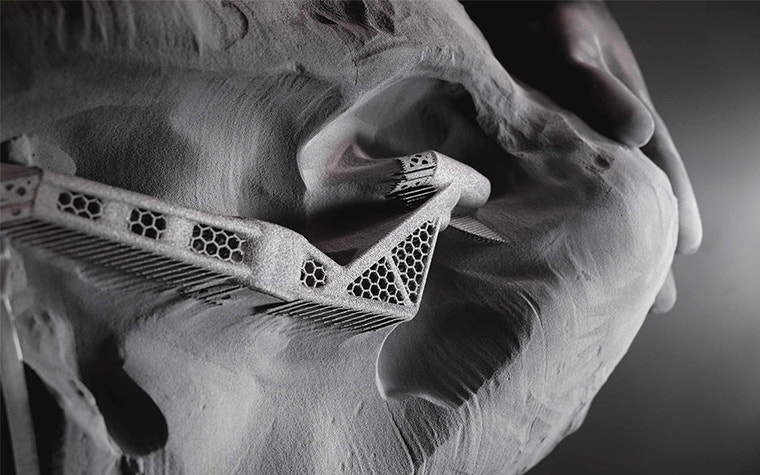

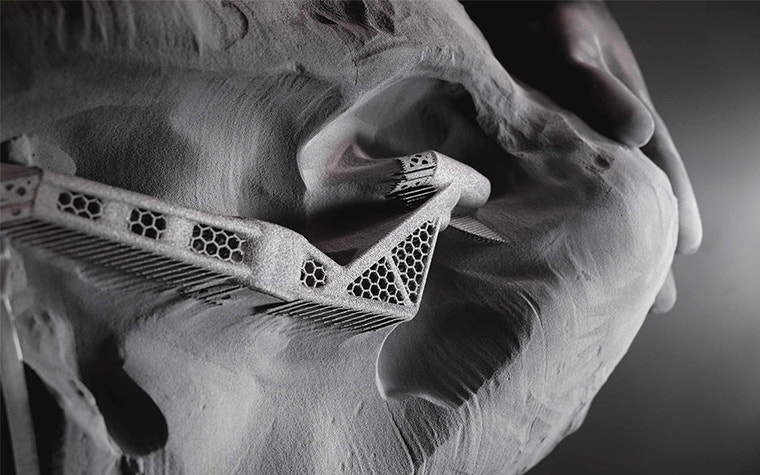

So, we’ve gradually increased our numbers. We started with one license for the company, and now we’ve moved that up to three licenses, just basically to meet our growing customer needs. We’ve always had SG Modules to generate support, and we’ve always had the Structures Module. But most recently, we’ve also started to use the Sinter Module for 3D nesting, which is really increasing our productivity and allowing us to increase the amount of build density that we’re working with.

What improvements have you noticed in your 3D printing processes compared to the early days?

One of the nice things is with electron beam melting (EBM), you can fully utilize the whole 3D build volume. So, you can float parts, and you can even have parts that are inside each other, like a babushka doll. And so, you can get extremely high nesting densities.

But previously, we had to do that all manually, and it would take hours. With the Nesting Module, it can now happen at the click of a button, so that has increased our ability to nest more parts on a build and bring down lead times.

Mass labeling is another tool that’s been really useful. Because we work in highly regulated industries such as aerospace and medical, you need to have labeling on every part, and again it reduces the number of staff hours required to launch a build.

How do you see your business evolving in the future? What is the role of AM in that evolution?

At Zenith Tecnica, we really pride ourselves on being a leader in Titanium EBM. We will be continuing to expand our capabilities and capacity for all our customers, of which additive manufacturing is our core.

Do you believe AM can play a role in making your manufacturing more sustainable?

With additive manufacturing, you’re really only using the material you need to build a part, and so inherently there is less waste. For us, we’ve been running a process of understanding powder recycling since 2014, and we’ve got over five years of mechanical and powder data on that. You might hear that there are different powder mixing strategies, and if you’re not doing this, you’re not being very sustainable.

But on the other end of the spectrum, you also have to know what you’re doing and how that could impact the mechanical properties. We’ve invested a huge amount of resources into getting our process tuned — now we have a very, very low scrap rate of powder, so it turns into a very sustainable process.

How would you like to see the additive industry evolve?

I would say in the additive space, seven years ago, one of the biggest challenges was getting customers to have confidence in the material. But that’s actually changed now. People are very, very comfortable and confident in additive manufactured parts. Now it’s all about how much complexity you can handle. When you’re dealing with parts that are made up of triangles, the more complex it’s getting, the bigger the files get, so everything comes down to faster processing and better hardware utilization. There also aren’t a lot of EBM users worldwide, and it would be really great to see a simulation tool for EBM.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.