EXPERT INSIGHT

30 Years of Innovation: How Stereolithography Sparked Materialise’s Inventive Ethos

Stereolithography established the 3D printing industry in 1986, signaling a revolution for the manufacturing industry. Discover how Materialise fine-tuned the first-ever 3D-printing technology, and developed an alternative printing method with its own large-format Mammoth 3D printer.

In 2020, we celebrated Materialise’s 30th anniversary. Our 30 Years of Innovation blog series highlights some of the different 3D printing technologies that have helped our customers achieve their ambitions over the years and shows that there is no one-size-fits-all approach to 3D printing. This time, it’s the turn of stereolithography.

Manufacturing was revolutionized in 1986 when the introduction of the stereolithography machine established the 3D printing industry. It was a huge step forward for the manufacturing industry and unlike anything ever seen before. Suddenly, designers could take an idea from concept to final product in just hours. The possibilities of all that could be created with this new technology felt limitless.

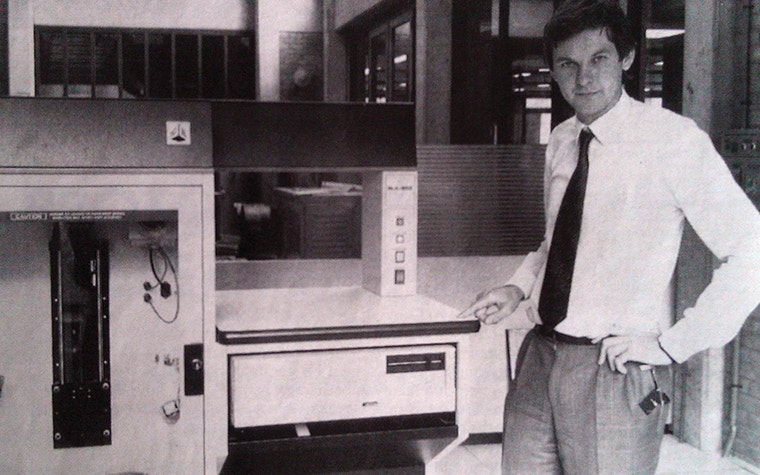

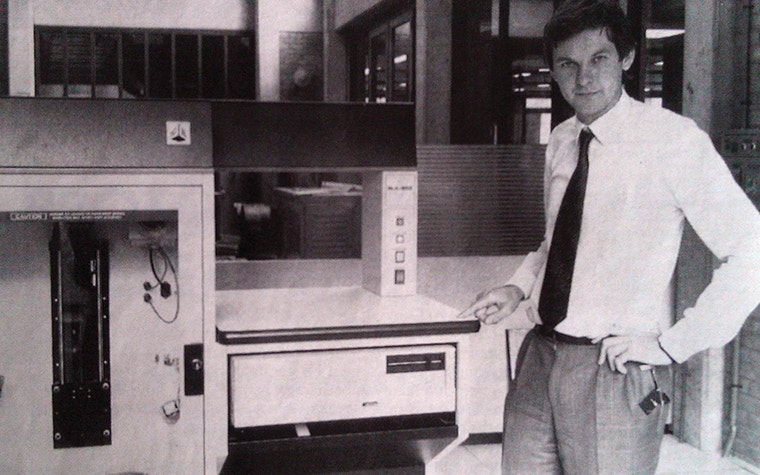

Four years later, Fried Vancraen decided to purchase a stereolithography machine — the second of its kind in all of Europe — and founded Materialise. Fried was fascinated by the power and potential of this technology and was attracted to the many possible solutions and applications empowered by it. With the power of stereolithography in the hands of the small group of forward-thinkers that started Materialise, an innovative company was born. Innovation began at Materialise immediately with this new, revolutionary technology, and this inventive mindset has only grown as decades passed, including various advancements in stereolithography.

Not just thinking big, but thinking better

During Materialise’s first decade, the pioneering team continued printing, but they wondered how they could make stereolithography even better. They ran into a few issues with the first machines on the market: the recoaters came into contact with the layers as printing progressed, resulting in frequent breaks and flaws that required the team to begin the print from scratch again.

So, they decided to tackle these issues head-on by developing a curtain recoating machine of their own: the Mammoth printer.

“Day after day, we prove that stereolithography is a technology that continues to add incredible value in the AM landscape.”

— Toon Roels, Director of Process Engineering and Quality, Materialise

Upon thinking of a Mammoth printer, you’d probably expect a rather large machine. And that it is. However, the size wasn’t their driving motivation to create the machine, but rather the result of the well-rounded and powerful machine that they desired.

“The overall robustness of the technology has allowed us to build such a large machine,” explains Toon Roels, Director of Process Engineering and Quality, Materialise. “This alternative method to depositing layers increases users’ chances of successfully depositing a layer and completing a build simply because there is no physical contact with the recoater.”

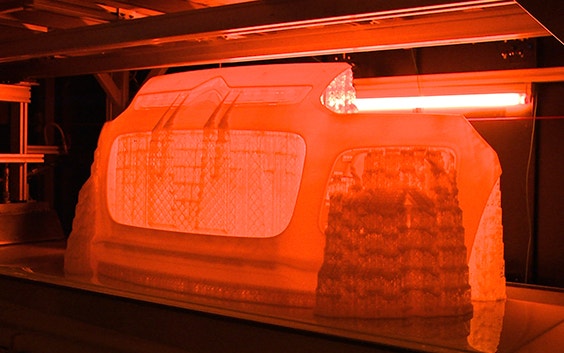

By developing a stereolithography printer that did not require the recoaters to come into contact with the layers, the team ended up with a machine that was faster, more productive, cost-effective, and could print multiple parts in one build or parts up to two meters long in a single build. Now, car bumpers could even be printed in one piece, which was a major contributing factor to the automotive industry becoming an early adopter of Rapid Prototyping.

When the team first introduced the Mammoth machine and its prints in 2000, others in the industry could clearly see that Materialise was a forward-thinking company that would be constantly looking to advance the field.

Evolving alongside 3D printing’s pioneer technology

Although it has been over 30 years since the stereolithography machine was introduced and many 3D printing photopolymer variants have been developed since, the traditional, vat-based stereolithography technology still holds a significant position in the additive manufacturing (AM) landscape. Its dimensional accuracy and high surface quality make it a reliable choice — and Materialise’s decades of experience with stereolithography have resulted in the team becoming top experts at designing and perfecting applications with it.

“Stereolithography is a powerful tool in the hands of those with a deep understanding of 3D printing, and the Materialise team has the knowledge and experience to create truly impressive designs with the technology,” says Toon. “Day after day, we prove that SLA is a technology that continues to add incredible value in the AM landscape.”

As stereolithography developed over the years, Materialise kept pace by introducing new materials and testing the technology’s capabilities with incredible prints. Currently, Materialise offers nine materials for stereolithography and is the technology of choice for transparent parts. The most recent material Taurus, combines the high surface detail enabled by stereolithography with its unique charcoal black color and strong mechanical properties.

“When I saw our first test builds in Taurus come off the platform, I was really impressed. It just doesn’t look like your average stereolithography material,” says Jonas Van Eyck, Process Engineer, Materialise.

Taurus is ideal for prototypes that need the look and feel of an injection-molded part.

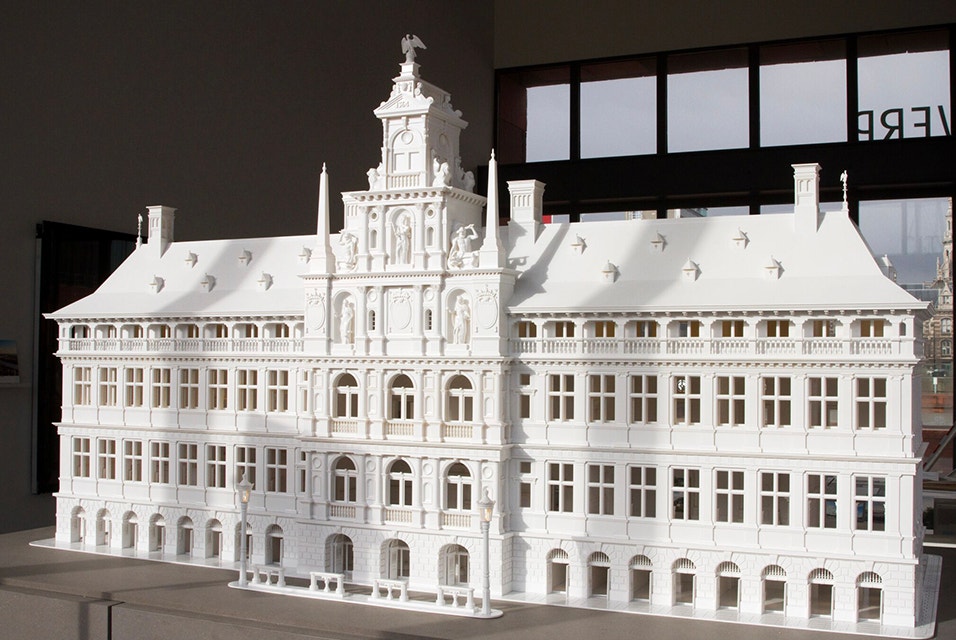

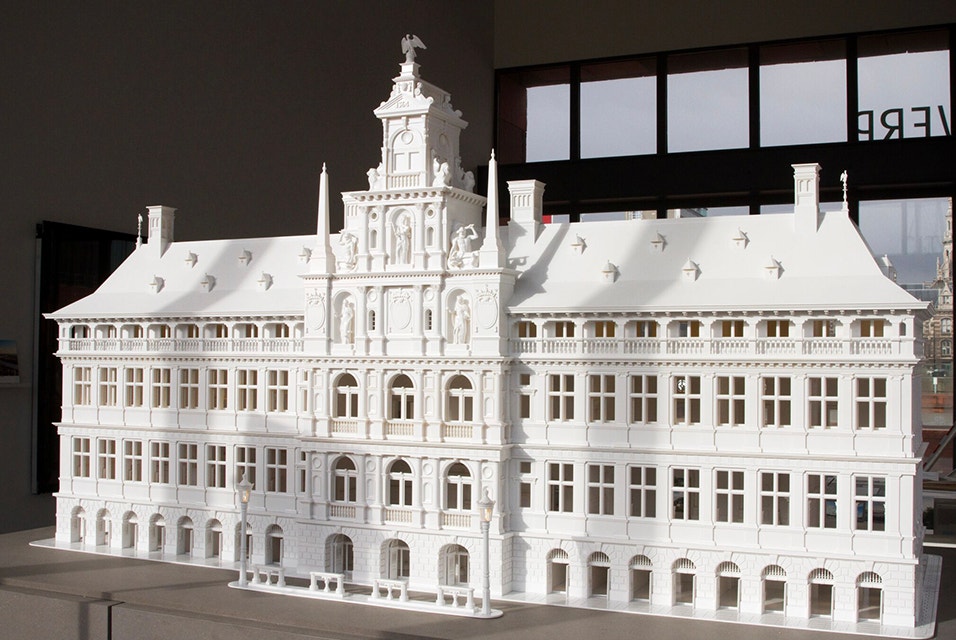

Alongside the variety of material options came truly notable applications. Because of the technology’s high accuracy and quick production time, it is ideal for prototypes, display pieces, and end-use products with intricate geometries and limited shelf lives.

Although stereolithography materials are not the strongest, the advantages of high dimensional accuracy and high surface quality can still be employed in applications with limited shelf lives. Two perfect examples of this are the TetraShell method, which uses an intermediate stereolithography pattern to cast a metal part, and using stereolithography as a master model for vacuum casting. An example of stereolithography becoming more durable to last through the years is this jaguar model created to thrive as a display piece on the tip of a yacht.

Materialise’s innovative mindset was first proven in 1990 with the creation of the company inspired by the potential of stereolithography. Throughout the years, Materialise has especially proven that innovation is in the company’s DNA when it comes to stereolithography, as demonstrated by the development of the Mammoth printer, the use of a wide variety of materials, and the production of hundreds of incredible prints.

As for the future of stereolithography, there are still many ways in which the technology can continue growing and advancing the industry. Since it’s an all-in-one chemical process, the material options can be created in small batches as needed that require much less energy than physical 3D-printing technologies. A chemical process such as this enables many possibilities for sustainably improving available materials, which we at Materialise look forward to.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.