Technology

Somos® TetraShell™

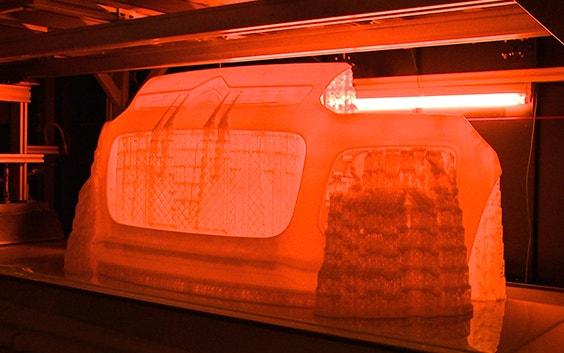

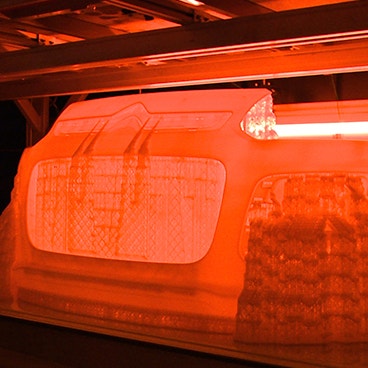

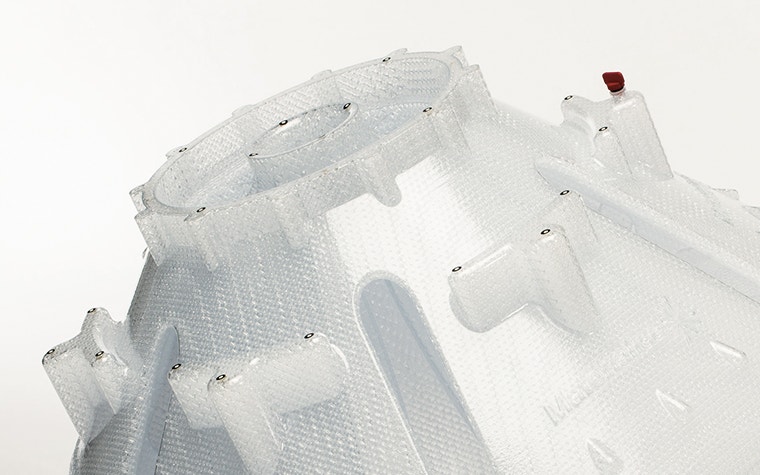

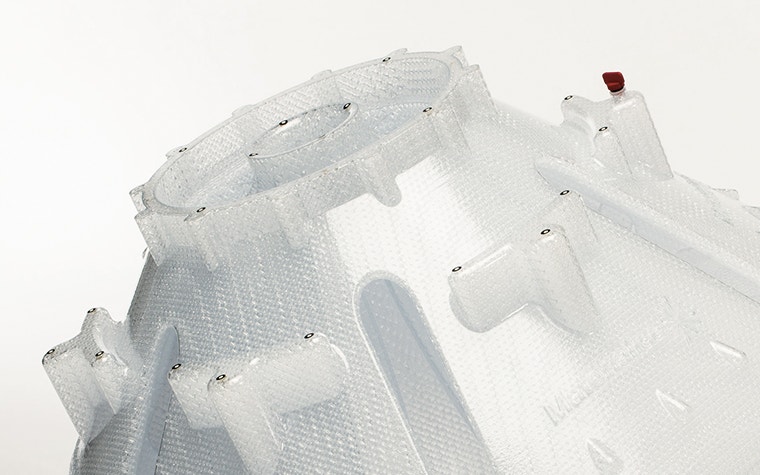

DSM Somos TetraShell software converts solid 3D design files into lightweight, hollow models that can be 3D printed using stereolithography to create high-quality patterns for investment casting or lost wax casting. As well as being well suited for creating prototypes, these 3D-printed patterns are ideal for tool validation and for casting small series of metal components.

Why work with Materialise Manufacturing?

Pairing TetraShell software with Materialise's stereolithography expertise lets you create high-quality, 3D-printed patterns for your investment casting or lost wax casting projects, eliminating the need for time-consuming and expensive tool production. With our patented Mammoth printers, you can even print patterns up to two meters long in a single build, reducing the risk of surface flaws.

Discover applications of Somos TetraShell

Technical specifications

| Maximum build dimensions | The maximum build envelope is 2,100 x 700 x 800 mm |

| Standard accuracy | ±0.2% (with a lower limit on ±0.2 mm) |

Materials

For Somos Tetrashell projects we use TuskXC2700T.

TuskXC2700T

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700T is a strong material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes and high-end finished models. Transparent finishes possible.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Great surface quality, with transparent finishes possible

- Among the largest printing volumes of stereolithography materials

- Fast Lane service available for online orders of TuskXC2700T – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 2,000 x 700 x 788 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

Work with us: discover our products and services

Need high-quality casting patterns for your next project? Discover the services that can help you do it.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Train and learn

Get more from your next project with helpful resources dedicated to 3D printing and Somos TetraShell.