TRENDS

6 Trends in Point-of-Care 3D Printing in 2021

In 2020, industries across the board suffered unprecedented disruption due to the global coronavirus pandemic. Many showed remarkable resilience, and none more so than the healthcare industry, which delivered heroically despite intense capacity, supply, and workforce challenges. The COVID-19 pandemic unequivocally highlighted the need to reimagine and reshape healthcare. At the same time, the crisis revealed the potential of innovative technologies like 3D printing to respond to critical needs, making it no surprise that the adoption of 3D printing in hospitals (i.e. point-of-care 3D printing) continues to raise.

While 2020 was a year of struggle, 2021 will hopefully be a year of transition towards a more future-oriented approach to healthcare where innovative technologies are used to their full potential.

Here are the most important trends to look out for in 2021 in terms of point-of-care 3D printing:

1. Broader 3D printing applications in healthcare

In 2020, shortages of essential healthcare materials — due mostly to long supply chains that were repeatedly disrupted by the pandemic — increased awareness of the value of having 3D printing capabilities at the point of care. Offering speed and versatility, 3D labs can easily and quickly adapt to changing circumstances, repurposing resources as needed, e.g. shifting focus from printing anatomical models for surgical planning to printing personal protective equipment.

With availability of supplies still unpredictable in 2021, 3D printing stands as a trusted and reliable ally in the face of fluctuating supply chains. Necessity, as the driving force for invention, is likely to broaden the use of 3D printing applications in healthcare.

2. Digital communication and remote collaboration

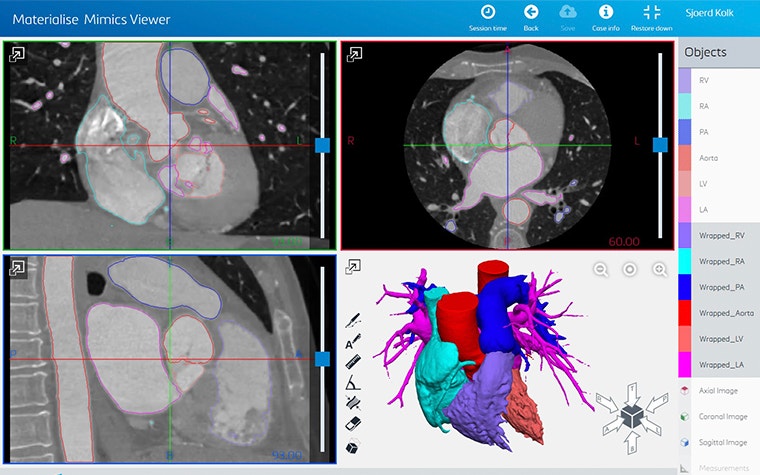

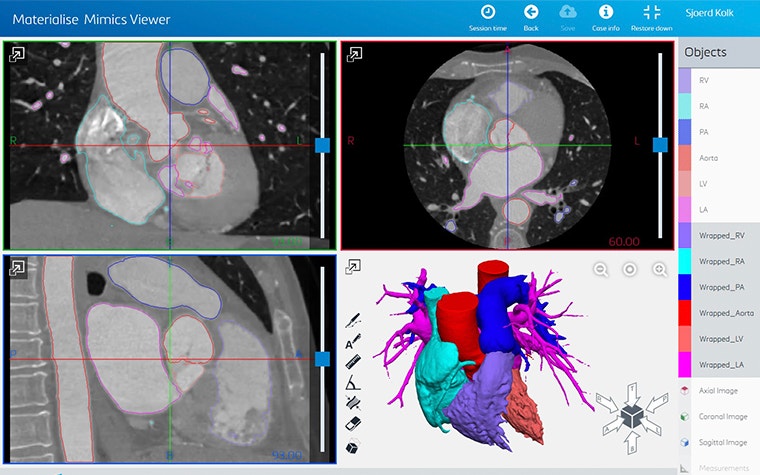

With social distancing firmly established in our everyday lives, new ways to communicate and collaborate effectively are becoming more necessary than ever before. In terms of healthcare, this rapid acceleration in digitization will lead to increased demand for and provision of telemedicine, i.e. remote diagnosis and treatment of patients. Digital technologies for patient-clinician, clinician-clinician communication, as well as communication between clinicians and point-of-care 3D printing labs, will become essential, and barriers to their widespread adoption will be much lower than in the past.

Materialise Mimics Viewer, an online platform that can be used both on desktop computers and mobile devices to share 3D patient models, planning, and device designs, supports this need for more efficient digital communication and collaboration. Intuitive yet powerful in its capabilities, the platform allows clinicians view cases and provide feedback in a clear, user-friendly way, eliminating the need to be in the same physical space as physicians or other engineers.

3. Complementing 3D printing activities with virtual and augmented reality

Once only in the realm of video games, advanced visualization technologies like virtual and augmented reality are now gaining pace and importance in clinical practice as a complement to 3D printing applications. Their potential has been amplified by advances in hardware capabilities and the availability of targeted software applications. Accessibility has also increased dramatically thanks to more affordable devices. This is sure to boost adoption not only for visualizing clinical cases and training purposes but also to support the rapid prototyping of devices and possibly even aid surgeons in the operating room.

The immersive nature of advanced visualization will bring communication and collaboration to a new level. Materialise now supports virtual reality, complementing 3D printing as a faster, low-cost solution for remote planning and collaboration.

4. Increasing importance of quality management systems

Delayed by a year due to COVID-19, the European Union’s new Medical Device Regulation (MDR) will be fully applicable as of May 2021. Across the EU’s Member States, point-of-care 3D printer manufacturers will be able to operate under the MDR’s article 5 exemption on several conditions. These conditions include a stipulation that printed medical devices are only used within the legal entity in which they were created, and that the hospital has an appropriate quality management system (QMS) in place.

In the United States, legislation surrounding point-of-care 3D printer manufacturers is vague. However, with the rising adoption of 3D printing in hospitals, the need for quality management Systems is increasing.

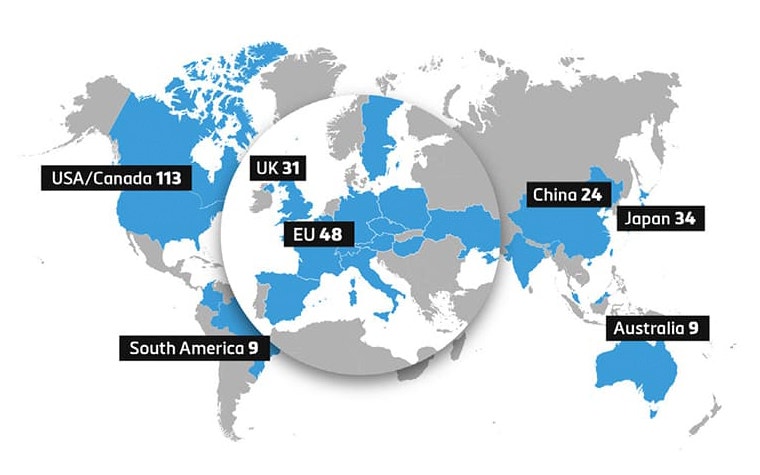

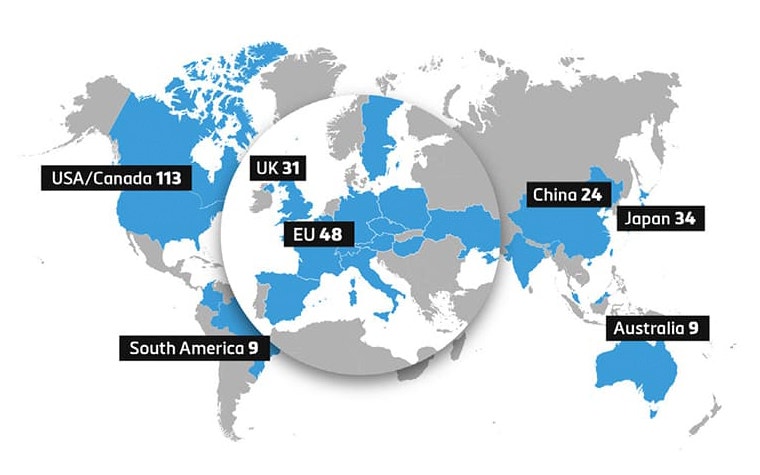

At Materialise, quality is at the core of everything we do. To support Ppoint-of-Ccare 3D printing facilities worldwide, we draw on our solid experience in quality management systems acquired over the last 30 years in medical device manufacturing.

5. Further integration of 3D printing in the clinical workflow

The update to the DICOM standard to include DICOM encapsulated STL and OBJ files has paved the way for greater integration of 3D printing and planning in the clinical workflow. 3D printing files can now be easily archived and retrieved in hospitals’ picture archiving and communication systems (PACS). This allows for easier traceability as it facilitates the linking of 3D imaging files with patients’ medical records.

DICOM encapsulated STL files are currently supported in Mimics Innovation Suite (MIS) 23, and the new DICOM encapsulated OBJ files will be supported in MIS 24, which will be released in May 2021.

6. Increased accessibility of 3D printers

3D printing technology is constantly improving, and 3D printing manufacturers are not only focusing their efforts on increasing quality but are also striving to make their machines more affordable. As a result, high-quality, medical-grade 3D printers are becoming more accessible.

Two great examples are the Form 3BL and J55, from Formlabs and Stratasys, respectively. The Form 3BL printer allows high volume 3D printing with minimal intervention. With the launch of the J55, Stratasys makes the efficiency and quality of PolyJet technology more affordable and office-friendly than ever before and enables natural color printing.

Increasing affordability of 3D printing technologies will fuel the adoption of 3D printing at the point of care and stimulate the development of new healthcare applications.

L-101828-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.