CASE STUDY

The Spider Bracket: A Topology Optimization Project by Altair, Materialise, and Renishaw

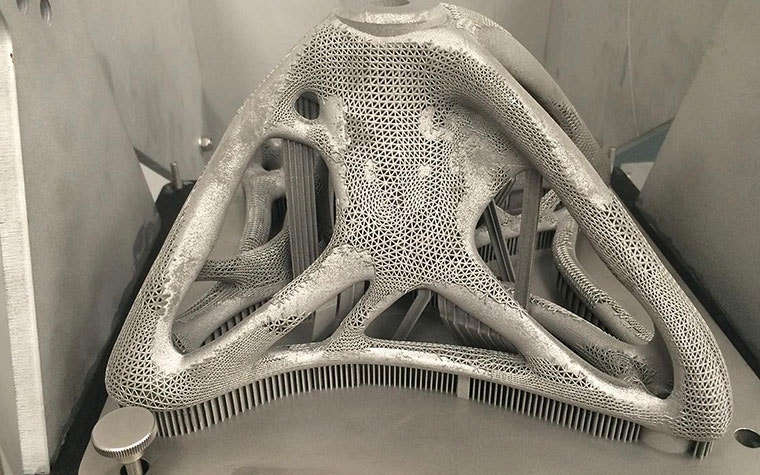

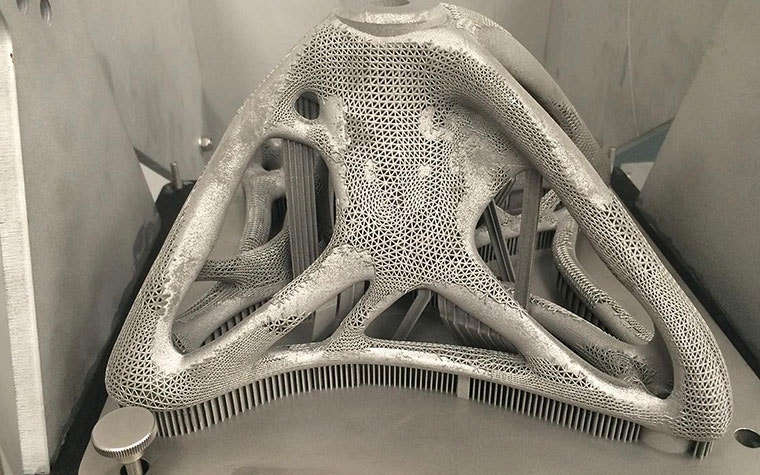

Materialise worked together with Altair and Renishaw to create an R&D spider bracket. The original design was based on brackets that connect the corners of architectural glass panels, used in atriums and floor-to-ceiling wall glazing. The amazing thing about this bracket is that it contains hybrid lattice structures and is successfully 3D printed in titanium. This design could not have been created with conventional manufacturing methods.

Following the organic shape of nature

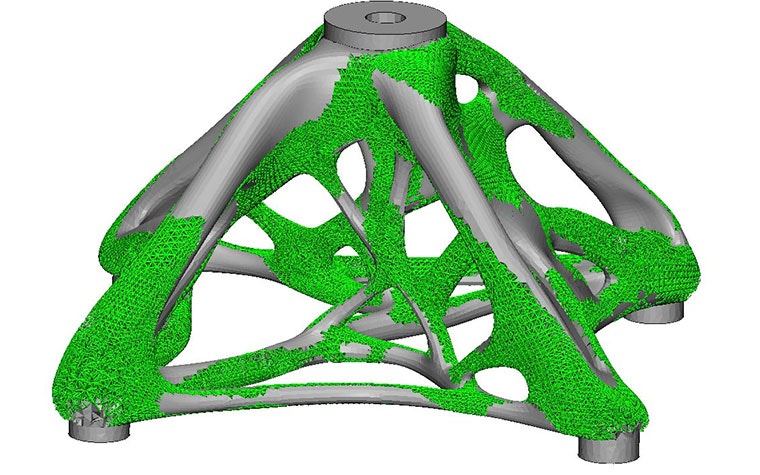

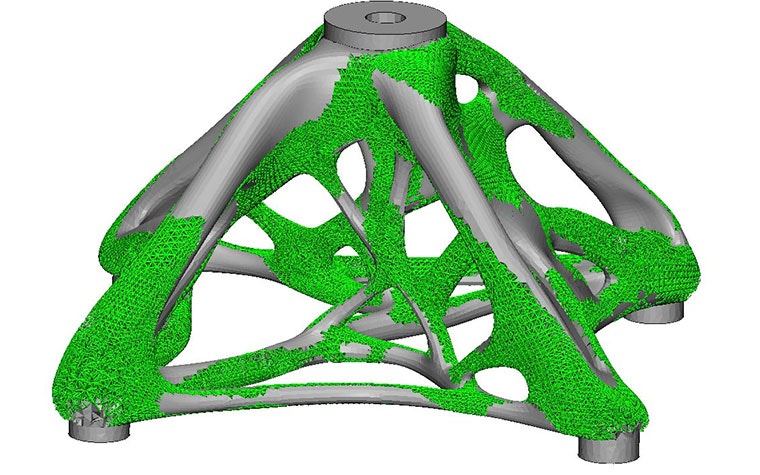

The spider bracket mimics the biological structures that can be found in nature. Altair’s topology optimization software created a unique, organic shape that is both light and strong. The lattice structures also provide stability and are desirable for thermal behavior. However, a topology optimized model needs sufficient smoothing before it can be printed.

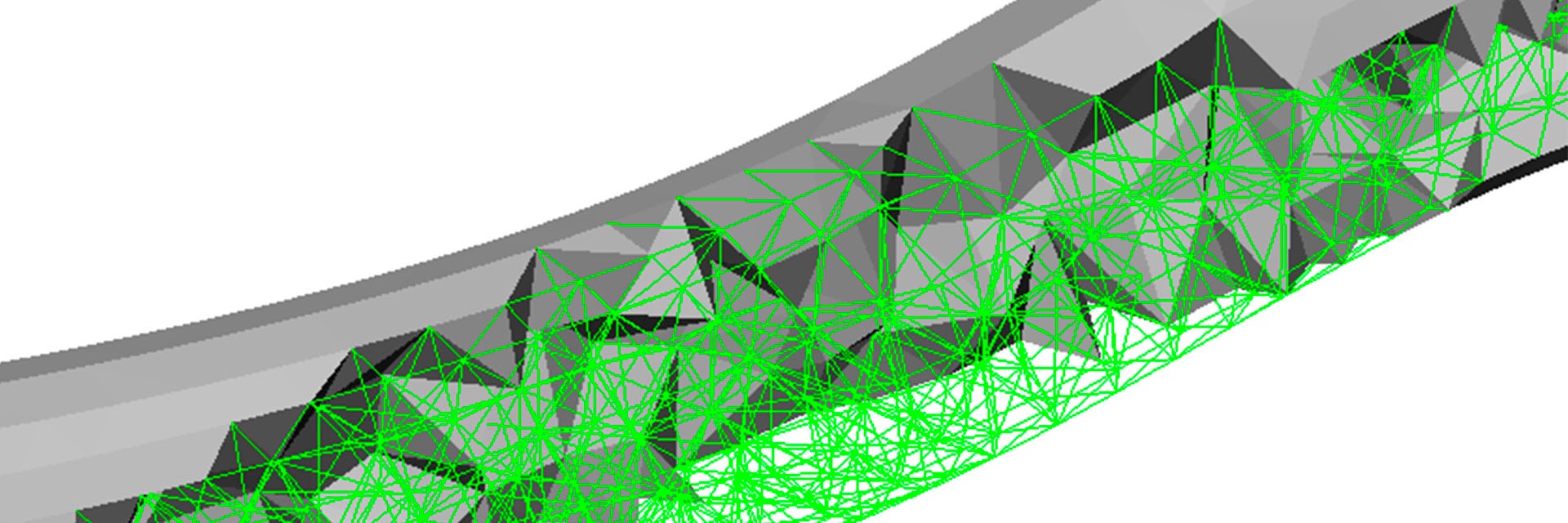

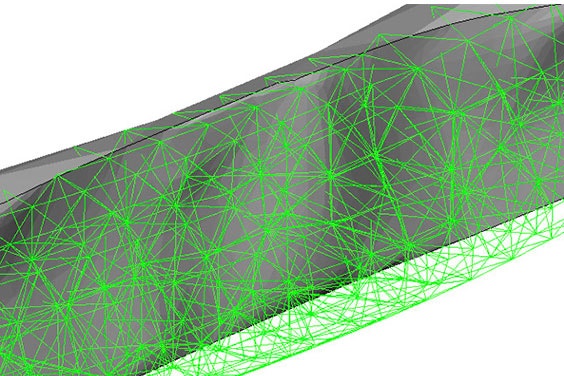

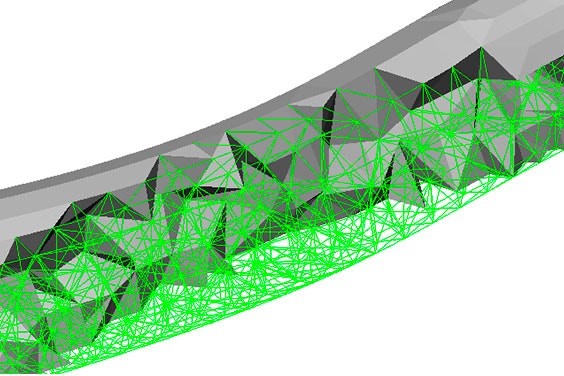

The topology optimization resulted in solid regions and regions with a lattice structure. The irregular interface between the lattice and the solid mesh makes 3D printing difficult and can lead to stress accumulations. This means that the edgy geometry needs reconstruction. That’s where Materialise 3-matic software comes into play. With this design optimization software, the design engineers at Materialise easily transformed the rough data into a clean model with smooth surfaces.

Rough data Smooth surface

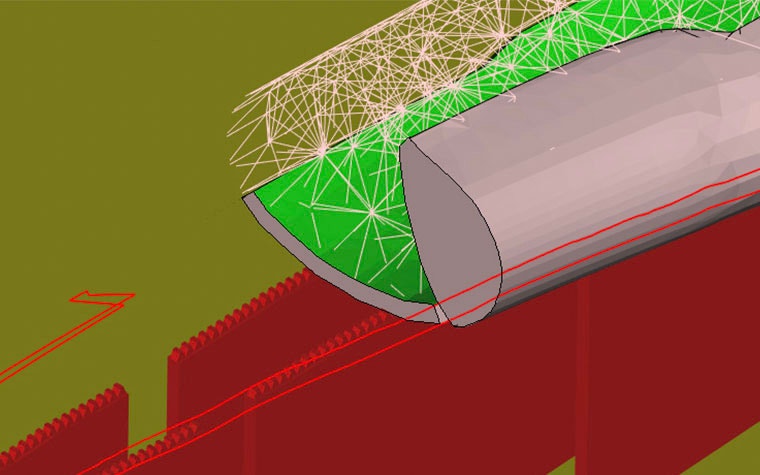

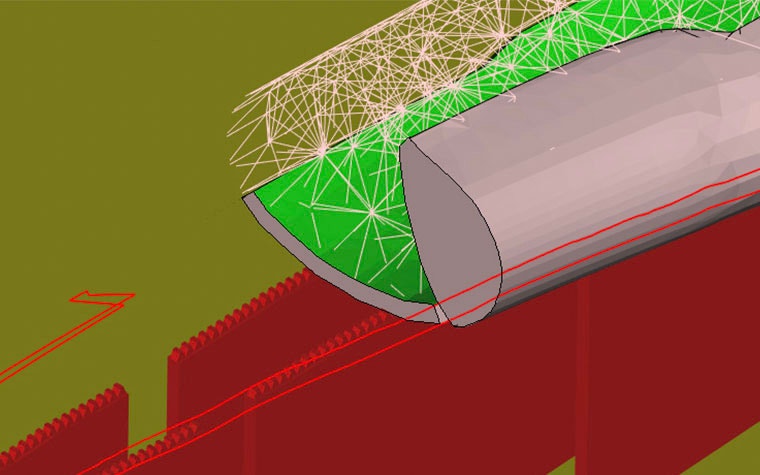

Besides the irregular geometry, the support structures attached to the lattice could potentially cause problems in laser melting processes. For instance, when you remove the support, the lattice structure can break off as well. To prevent this issue, our engineers placed a thin layer of solid material under the lattice structures that needed support. At certain regions, the design was also slightly improved with Materialise 3-matic to reduce the amount of support structures necessary.

Data preparation for metal 3D printing

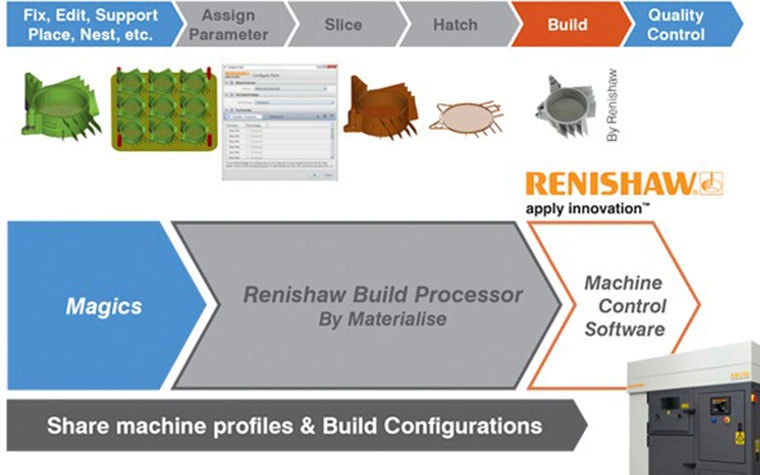

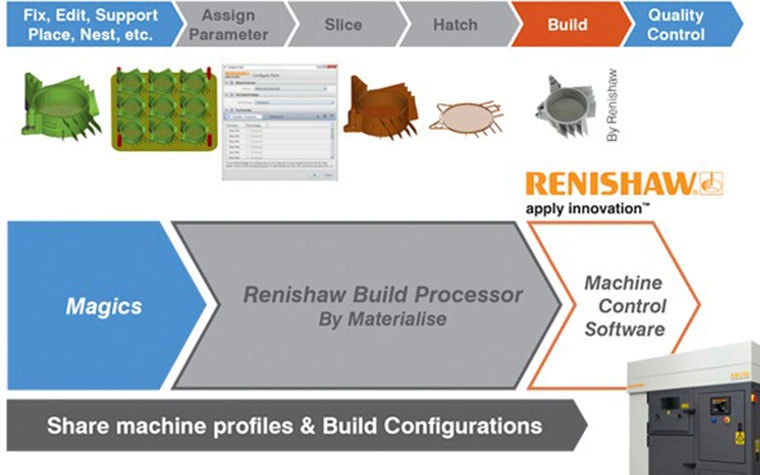

After design enhancement, the engineers used Materialise Magics to add logos of the three companies, find the optimal orientation, position the part within the build envelope and generate support structures. Good support structures fulfill a larger purpose than just supporting the part during the build process. It also minimizes deformation so that the build process will not be terminated.

With our Support Generation Module for metal, it was possible to anchor the part and transfer the heat.

The final stage

Normally the large and complex file would be difficult to handle and manipulate, but in this case the calculations of the structures were postponed until the slicing step. The slice-based technology of the Renishaw Build Processor by Materialise applied the 3D geometry of the spider bracket at the slice level instead of at the STL level, which kept the file size remarkably low.

The build file was thus sliced and tested according to Renishaw assigned material parameters. After this, the file was turned into a titanium part thanks to the expertise and technology developed by Renishaw.

“For every 3D printing project, it is essential to determine whether a part can be successfully printed. To do this, Materialise has developed an entire backbone of software solutions to verify and help ensure the printability of even the most complex of parts. In the case of the spider bracket, our slice-based software ensured the printability of the lightweight structure generated by Altair’s OptiStruct team by creating a more manageable ‘lightweight file’. This data was then seamlessly transferred to the machine by the Renishaw Build Processor by Materialise, helping turn an impossible project into a 3D-printed reality.”

— Lieve Boeykens, Business Line Director for 3D Printing Professionals at Materialise.

The striking spider bracket has been built successfully, translating almost 4GB of data. The never-seen-before design and the unique mix of solutions that were used provide an insight to the new era of shapes and products to come in metal 3D printing.

Share on:

This case study in a few words

3D printing service provider

Materialise Magics

Materialise 3-matic

Materialise Build Processor

Successfully smoothing and printing a complex titanium bracket

Creating optimal support structures

Applying slice-based technology

How we helped

Optimize and automate support generation with options tailored to different materials, technologies, and geometries.

Generate lattices, create textures for an aesthetic finish, and achieve post-topology optimization.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Slice and send jobs to 3D printers based on machine-specific strategies or optimize custom scan path strategies with our software development kit.