EXPERT INSIGHT

Innovating for Sustainability: Software Solutions to Minimize Waste in 3D Printing

Sustainability is ingrained within our company mission. It’s not only our goal to use more sustainable processes within our own facilities but also to ensure that we’re providing our customers with sustainable choices as well. The enabling factor behind these choices has remained the same over the years: research.

Materialise is built on innovation, so it’s no surprise that a major way in which we contribute to progress in sustainability is through research and developing new solutions. In particular, our software department has made this mission a cornerstone of their work.

Manufacturing as a whole is seen as an industry that results in too much waste. Excess plastic packaging, wastewater, and energy used to power facilities litter the headlines. Any progress towards sustainable manufacturing helps, and in additive manufacturing (AM), that ranges from reducing scrap to minimizing machine run-time. 3D printing software plays a large role in improving all these factors.

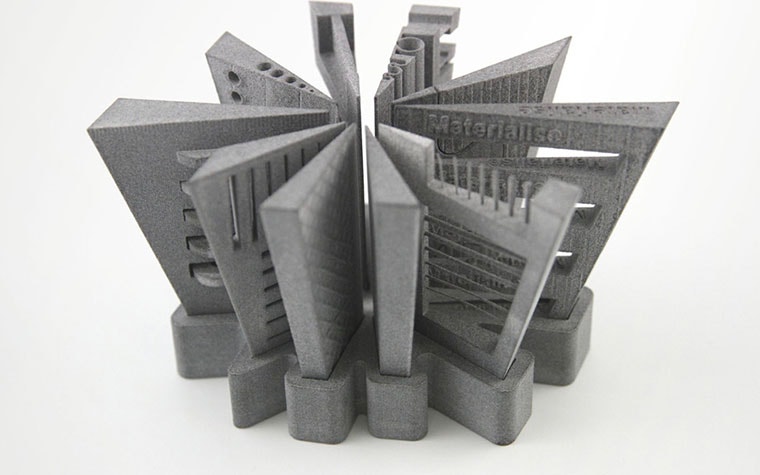

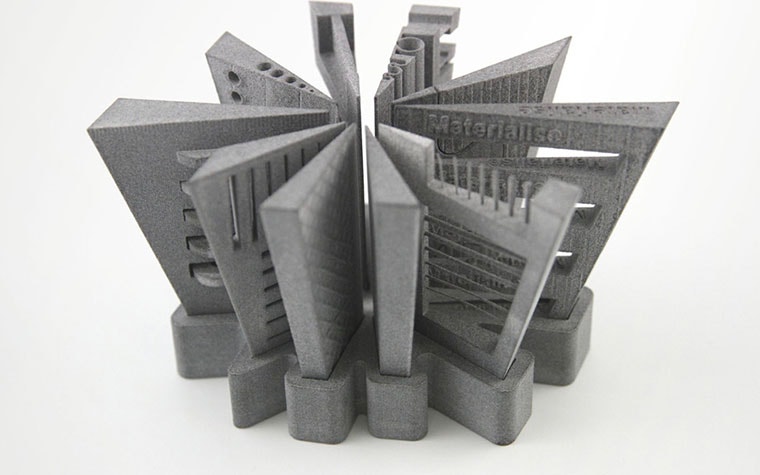

Our software department leans heavily into research to promote sustainable processes via our solutions. It’s an essential step in our approach to developing new products or updating existing ones. Take, for example, version updates for our industry-leading data and build preparation software: Magics. Our aim towards more sustainable processes has led to innovations such as the optimization of nesting workflows — a step that, when done effectively, plays a major role in waste minimization. Read on for more examples of sustainable advances thanks to software research.

Faster builds for less energy

One component of the 3D printing process that our team leveraged research to optimize is 3D printer efficiency. Although we don’t produce 3D printers ourselves, these machines are run by software that we have 30+ years of experience developing. 3D printing is highly dependent on the software behind it, so it’s a crucial step in making a more sustainable process.

Thanks to this focus on research for improved printer efficiency, we are today able to offer our software line that supports 3D printers with multiple lasers. Although the industry largely offers printers with just one or two lasers, it was clear to us that this was the way forward. With the right amount of control over the lasers, “users can expect an increase in their machine productivity of 30 – 40% per additional laser with optimal parameters,” according to Research Manager Tom Craeghs.

And that’s where our software comes into play. Without proper control, these extra lasers won’t improve productivity in a meaningful way. But with software tools such as the Materialise Build Processor and the Materialise Control Platform, users can gain that control and ensure shorter run times (that ultimately use less energy) and less scrap. And it’s all thanks to the efforts of the research team.

Testing with less waste

Speaking of less scrap, this was one of the main motivators behind our ambition to create Materialise Process Tuner. When organizations want to introduce new materials or machines into their 3D printing productions, a lot of testing is required in order to check the material quality, adjust machine parameters, and more.

Unsurprisingly, testing in this way often led to the creation of extra 3D-printed samples that held no purpose and ultimately became waste. Process Tuner automates the creation of tests, not only reducing the time spent on this step but also minimizing the number of tests to just the necessary few. In fact, Rosswag Engineering began using Process Tuner in order to qualify materials for 3D printing and reduced time spent on data preparation by 90%. These time savings, plus the reduction in the number of experiments, transformed their process. With smart tools to streamline the qualifying process, facilities can both reduce the energy spent creating extra tests and the waste of tests that, in the end, didn’t add anything to their research.

Correct builds in real time to eliminate scrap

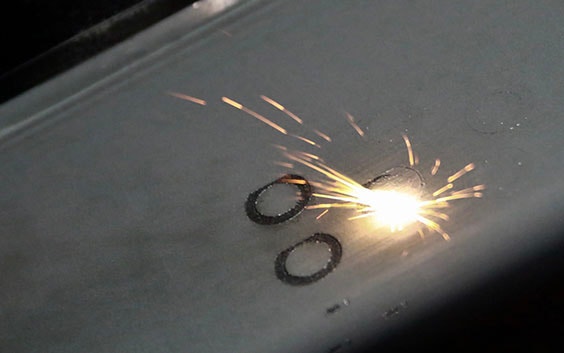

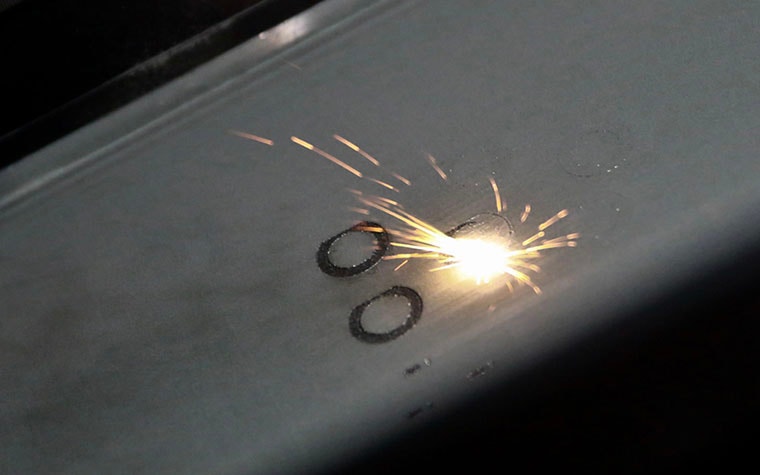

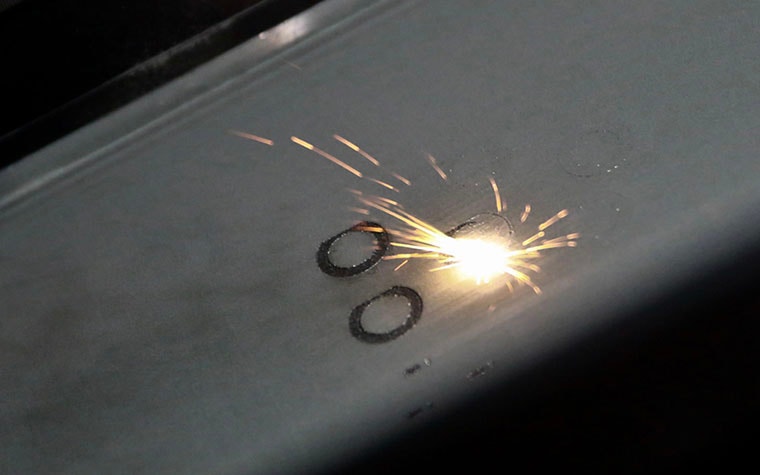

The final topic we’ll cover in this article is a research study that we completed alongside Sigma Labs. This project again leveraged our Materialise Control Platform as well as Sigma Lab’s PrintRite3D® sensor technology to adapt builds as they’re happening. As mentioned above, scrap is a significant cause of waste in additive manufacturing. So the ability to correct builds as they run and avoid failed prints altogether would be a major step forward.

In this study, our teams purposely induced local errors before printing. By integrating the two software solutions, they wanted to see if they could correct these errors in real time. And after printing two tests, using one as a control group, they discovered that our solutions could steer the system towards the desired energy density at the point of each induced error to correct the issues.

Although this solution is not ready to be applied on a grand scale just yet, the study showed promising results. It shows that real-time control over additive manufacturing is indeed a possibility, and more sustainable processes are within reach.

But it doesn’t end here. Innovation and sustainability are core values at Materialise, and it all starts with research. We’re committed to leveraging research to fully understand how our technology impacts the world and what we can do to decrease any negative impact. Our research is crucial for us to take action in empowering the industry with sustainable choices. We’re constantly working towards bettering the world, and we hope you’ll join us in this mission.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.