What to expect from this training

Additive manufacturing is a proven and valuable production tool for the medtech industry — this course is designed to help your team take advantage of it.

You’ll have the choice of up to four modules, each fully tailored to fit the needs of your company. Core topics include everything from the foundations of AM to best design practices for your preferred technology, giving you a complete pathway to adoption or allowing you to fill any gaps in your existing skillset. Work through the entire curriculum in order, or select only the modules that meet your needs.

Each session is hosted by an AM specialist with first-hand experience in delivering solutions for the medtech industry.

Practical info

Audience

Both technical and purchasing professionals in the medtech industry, including R&D, engineering, purchasing, and supply chain management.

Level

Any — we adjust the content based on your needs

Format

Online, in person — at our premises or yours

Price

Available upon request, based on your requirements

Training from an industry leader

35+ years of AM expertise

Every session is founded on over 35 years of knowledge and experience, including practical examples from medtech projects. Learn from multidisciplinary specialists with expertise covering process engineering, design engineernig, quality control, and manufacturing operations.

A proven name in the medtech industry

We work with 28 of the top 30 manufacturers in medtech, including Zimmer Biomet, Philips Healthcare, and DePuy Synthes.

Certified production facilities

We understand what it takes to produce compliant parts for the highly regulated medtech industry, whether through production traceability or material characteristics like biocompatibility.

A technology-neutral approach

With six additive manufacturing technologies in our portfolio, the only option we’ll insist on is the one that’s right for your project. By covering every option with you, we’ll ensure you get the best results.

Key modules

MODULE 1

Additive Manufacturing Foundations

Gain an understanding of additive manufacturing, including the different technologies at your disposal, its ideal medtech applications, and the key drivers for adoption. The output of this session will be a list of potential applications to further explore with your team.

MODULE 2

Application Development Workshop

In this module, you will develop 1 or 2 potential applications in detail. Working with your engineering team, you will assess suitable technologies and materials, identify (re)design requirements, and build your business case.

Each step considers product performance and regulatory requirements.

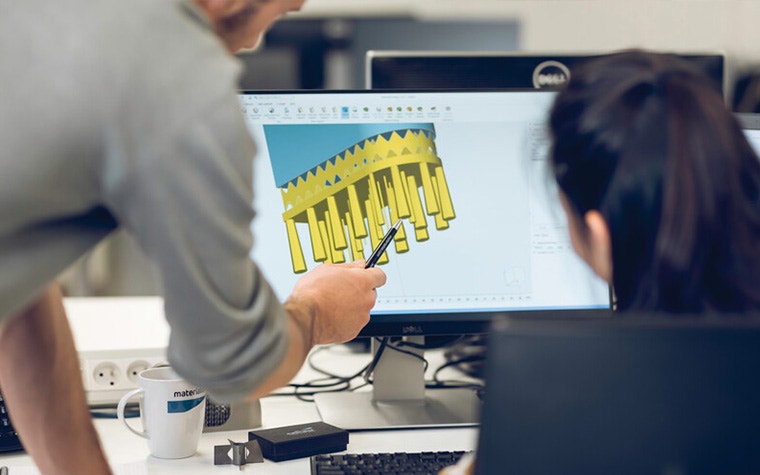

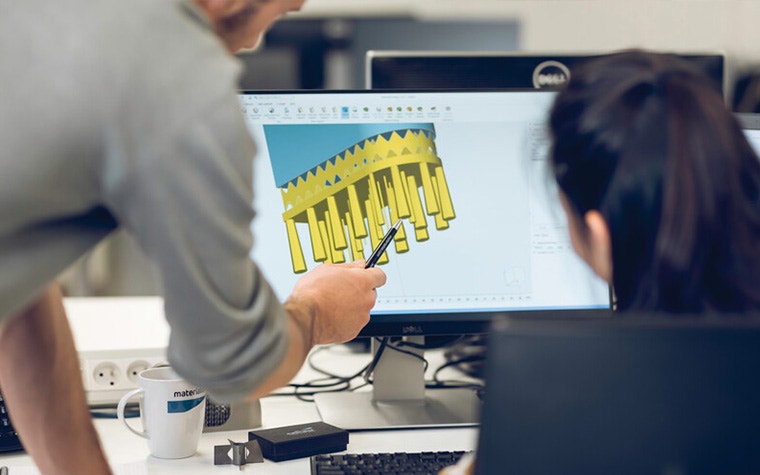

MODULE 3

Design for Additive Manufacturing

If your team has already identified a preferred AM technology, this module delivers a deep dive into the best design practices. Discover tactics to enhance scalability, reduce part weight, and improve part performance or functionality.

Technologies include selective laser sintering (SLS), vacuum casting, stereolithography (SLA), selective laser melting (SLM) and fused deposition modelling (FDM).

MODULE 4

Engineering Consultancy

Work directly with Materialise engineers in one-to-one sessions (online or off-site) over an extended period of time to fine-tune your AM projects and prepare designs for series production.

Continue learning

What's next in your AM journey? Check out our other courses to continue advancing your skills.

An ideal introduction to industrial 3D printing. An AM expert will guide you through the basics of the most popular technologies, plus when and where it makes sense to print your parts.

Discover various methodologies and workflows for metal 3D printing, plus gain insight into the cost savings, integrated functionality, and increased performance associated with design for additive manufacturing (DfAM).

Discover various methodologies and workflows for working with polymers, plus gain insight into the cost savings, integrated functionality, and increased performance associated with design for additive manufacturing (DfAM).