PRESS RELEASE

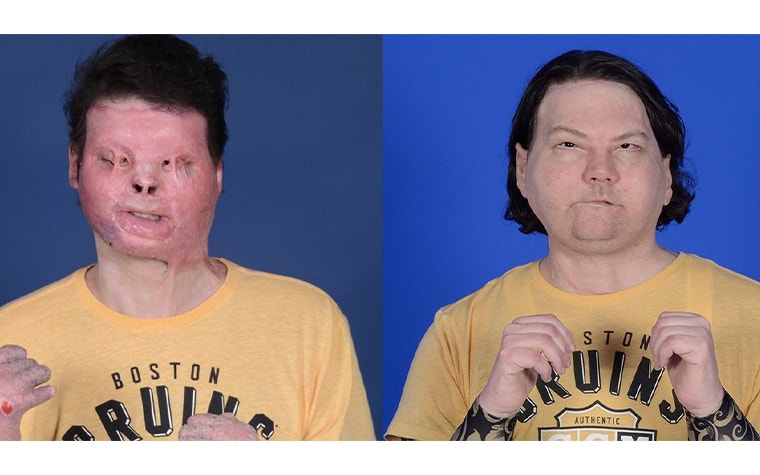

3D Technologies Support World’s First Successful Double Hand and Face Transplant

February 3, 2021

Materialise’s 3D printing and surgical planning tools provide increased speed and accuracy

New York - February 3, 2021. 3D technologies, developed by Materialise, played a crucial role in the world’s first simultaneous double hand and face transplant that was successfully performed at NYU Langone Health in Manhattan, NY. Materialise’s innovative 3D planning and printing tools enable the speed and accuracy required for such a complex medical procedure. 3D printed personalized tools such as those used in the double hand and face transplant, are also increasingly common for use in routine surgery, providing surgeons with an additional level of confidence which results in improved patient outcome.

The 22-year-old patient suffered burn wounds resulting from a car accident, leaving him with severe injuries to his face and both arms. He suffered significant damage to his soft tissue, which severely limited his ability to lead a normal life. During a preparation period of 14 months, Materialise clinical engineers formed a cohesive team alongside NYU Langone surgeons, rehearsing the operation in a lab environment to develop and fine-tune the surgical plan. Once a suitable donor was found, the team, led by Dr. Eduardo D. Rodriguez, the Helen L. Kimmel Professor of Reconstructive Plastic Surgery and chair of the Hansjörg Wyss Department of Plastic Surgery at NYU Langone, had only 24 hours to begin the procedure that would improve the patient’s function, appearance, and quality of life.

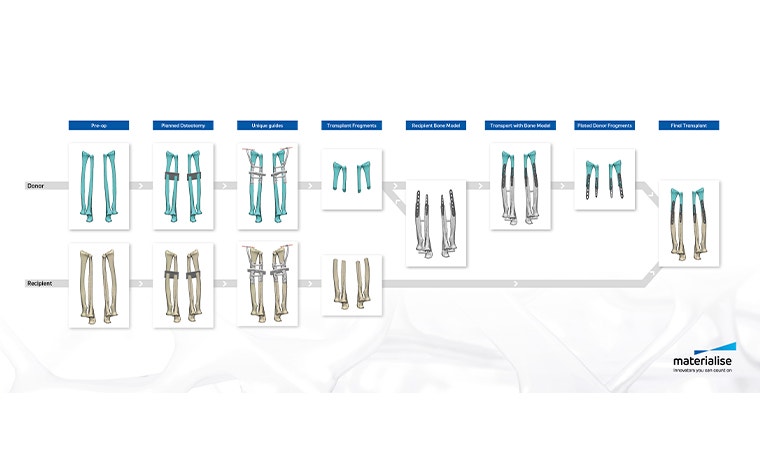

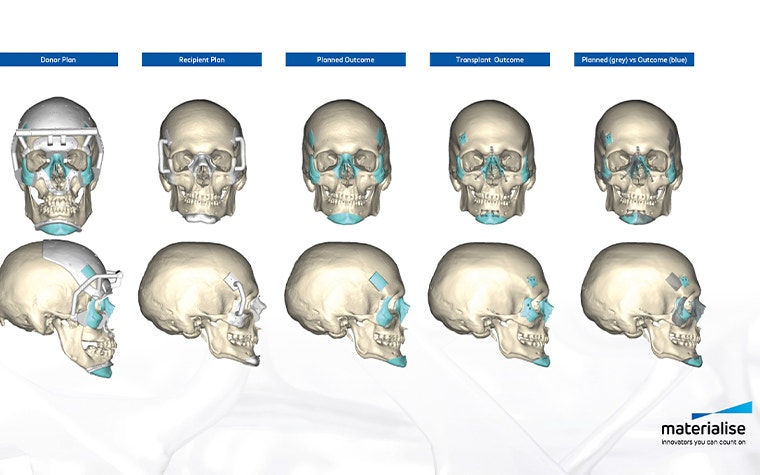

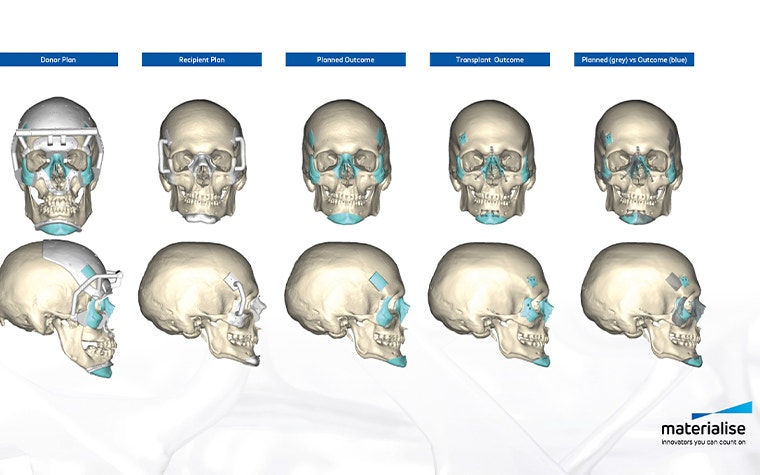

In the months leading up to the surgery, Materialise engineers coordinated the development of a surgical plan and created an on-screen 3D model based on CT scans. This allowed the surgeons and clinical engineers to virtually plan the procedure and visualize different scenarios in three dimensions, creating an in-depth understanding of the anatomical bone structure and determining the optimal surgical flow. Pre-surgical planning also made it possible for surgeons to virtually select and position various medical implants to predict the optimal anatomical fit. Once the surgical plan was finalized, Materialise 3D printed the personalized surgical guides, anatomical models, and tools for use during the transplant surgery.

During this momentous procedure, Rodriguez and his surgical team of sixteen used Materialise’s 3D printed cutting and drilling guides. This fully guided system for bone fragment repositioning and fixation was unique to the patient’s anatomy and helped position the medical tools with great precision, reducing the overall surgery time. Additionally, Materialise created 3D printed sterilizable identification tags for nerves and blood vessels, 3D printed models that were used during donor transport, and 3D printed splints, enabling optimal donor hand position during soft tissue reconstruction.

“Complex transplant surgery like this brings together a large team of specialists and presents new and unique challenges”, says Dr. Rodriguez. “This demands careful planning and makes timing, efficiency and accuracy absolutely critical. Virtually planning the surgery in 3D and creating 3D printed, patient-specific tools offers additional insights in the preoperative phase and increased levels of speed and accuracy during a time-critical surgery”.

“Image-based planning and medical 3D printing have completely revolutionized personalized patient care by providing surgeons with detailed insights and an additional level of confidence before entering the operation room,” says Bryan Crutchfield, Vice President and General Manager – North America. “As a result, leading hospitals are adopting 3D planning and printing services as part of their medical practices because they create a level of predictability that would be impossible to achieve without the use of 3D technologies.”

Materialise has pioneered many leading medical applications of 3D printing and enables researchers, engineers, and clinicians to develop innovative, personalized treatments that help improve and save lives. The Materialise platform of software and services forms the foundation of certified medical 3D printing in clinical and research environments, offering virtual planning software tools, 3D-printed anatomical models, and personalized surgical guides and implants.

About Materialise

Materialise incorporates three decades of 3D printing experience into a range of software solutions and 3D printing services, which together form the backbone of the 3D printing industry. Materialise’s open and flexible solutions enable players in a wide variety of industries, including healthcare, automotive, aerospace, art and design, and consumer goods, to build innovative 3D printing applications that aim to make the world a better and healthier place. Headquartered in Belgium, with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the largest 3D printing facilities in the world.

For additional information, please visit: www.materialise.com

L-101788

Materialise press contact

Pictures:

Share on: