COMPANY HIGHLIGHTS

Materialise and Proponent Lift Off with Historic Deal

February 23, 2022

Did you know that over four million pieces make up the Airbus A380? Normally, an intricate supply chain of manufacturers is necessary to get this machine off the ground, and aftermarket supply can often get complicated and costly. But additive manufacturing (AM) is on course to change all of that.

Partnering with Proponent, the world’s largest independent aerospace distribution company, gives us the chance to help both OEMs and MROs explore 3D printing for aerospace as a complementary technology and benefit from its ability to produce on-demand part series.

“The usage of 3D printing in aerospace companies is typically governed by specialist engineering departments. The decision of when to opt for 3D printing is treated as a technical one. From our experience at Materialise, though, we know that the on-demand nature of 3D-printed parts can answer pains that are more felt in purchasing: sourcing and stocking legacy parts, managing total costs, speeding up lead times. So what we want to do, by partnering with Proponent, is to make 3D printing more accessible,” explains Rico Engelman, Materialise’s Business Development Manager for Aerospace.

An intrinsic benefit of 3D-printed parts is the option to manufacture them in smaller production runs, contributing to sustainability targets while helping OEMs avoid stock risks from keeping legacy parts on hand, and simultaneously allowing MRO purchasers avoid high minimum order quantities.

Switch to the express lane with 3D printing

3D-printed parts can be manufactured and delivered quickly, without the disadvantage of needing extra storage or ordering in bulk. This is crucial for urgent requests that are quite common.

“There are a lot of 24 to 48-hour requests in the aerospace industry. When an aircraft is grounded, they need certain parts quickly. On the other hand, being able to reduce stock and only store what’s needed is important to original equipment manufacturers (OEMs). It’s a delicate balancing act. There’s a demand for fast lead-times, but manufacturing and storing legacy parts is a risk. On-demand production is the obvious solution,” states Rico.

After mapping the potential benefits of 3D printing for the aerospace aftermarket, the team engaged with Proponent, one of the leaders in the key growth sector. Rather than seeing 3D printing as a threat to the legacy store and ship model, Proponent embraced the potential of 3D printing and potential synergies with a partnership. The deal was concluded swiftly — and the agreement was officially signed in 2021 at MRO Europe. “MRO was the first trade show in the aerospace industry for a couple of years, so it was full of big announcements. Nevertheless, our news created a huge buzz in the 3D printing community, as we were the first to announce such a deal.”

In the initial stages of the partnership, Proponent and Materialise are working on spotting applications and aerospace parts that bring most benefit from the whole AM process. Our consultancy division is bringing its expertise in application development on board to identify the parts most suitable for 3D printing. Technical feasibility is only the start: the goal for Proponent and Materialise is to partner with OEMs in creating solutions that meet the industry’s needs.

Transforming the aerospace aftermarket

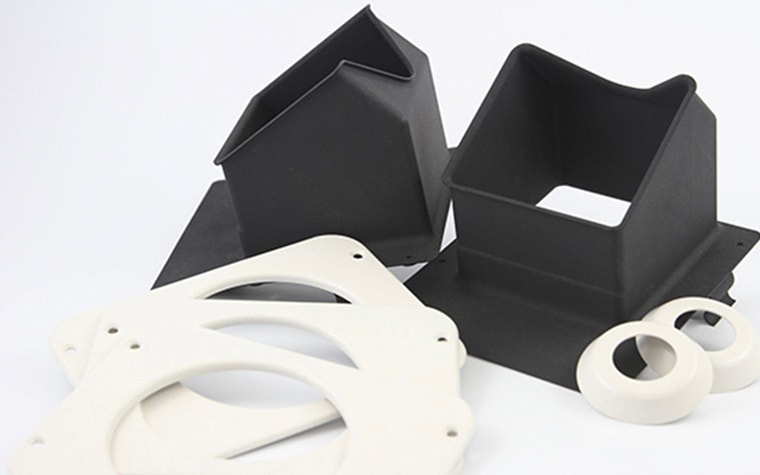

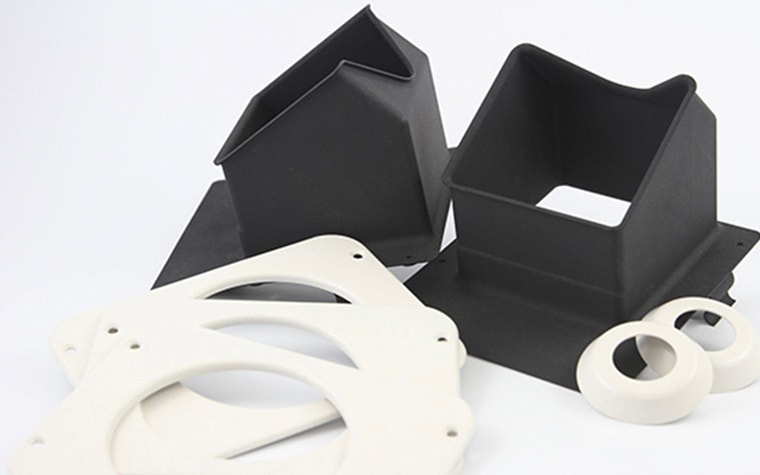

Materialise already has a wide range of certified 3D-printed parts for non-critical interior applications. Although, there’s scope to expand to other areas. Erik de Zeeuw, Materialise Market Manager, sees many advantages associated with 3D printing: “Once the industry switches its outlook and realizes the benefits and design freedoms that 3D printing offers, we’ll see the aerospace industry take off. We believe that spreading the word, giving guidance, and training engineers to think and design for AM will help facilitate this change.”

“The on-demand nature of 3D-printed parts can answer pains that are felt in purchasing: sourcing and stocking legacy parts, managing total costs, speeding up lead times. So what we want to do, by partnering with Proponent, is to make 3D printing more accessible to purchasers.”

— Rico Engelman, Materialise’s Business Development Manager for Aerospace

Building strategic partnerships with companies such as Proponent is a positive step towards developing the awareness of AM within the aerospace industry. But it’s just the beginning. Materialise’s expertise in all things AM — combined with customized training and application opportunities — pave the way for OEMs, MROs, and training firms to get on board with the idea of 3D printing. “The environment and awareness for 3D-printed parts will continue to expand in the future. There’s enormous potential for the whole industry to develop by embracing 3D printing.”

Share on: