Webinar

How to Achieve End-to-End Traceability and Scale the Additive Manufacturing Shop Floor

Discover how traceability and repeatability can be set up within the Materialise CO-AM Software Platform

About this webinar

Additive manufacturing (AM) companies need to keep track of key data across the entire 3D printing value chain to satisfy on-time delivery targets and ensure that quality and compliance requirements are met. But how can you achieve end-to-end traceability across your company and suppliers' processes?

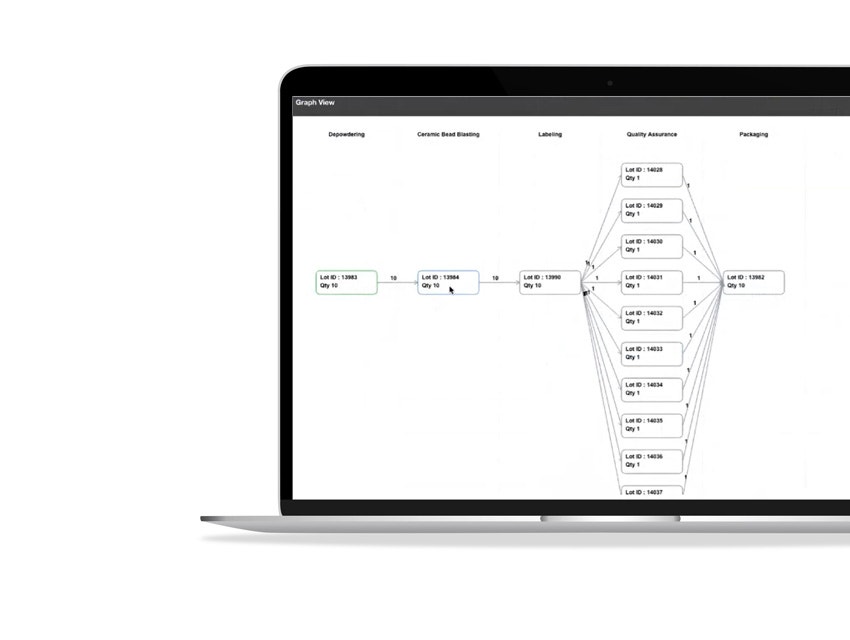

In this webinar, we'll show you how a single source of truth (SSOT) platform helps you track data and process AM workflows, from an entire build envelope to individual parts coming off the tray — ready to be post-processed, finished, quality controlled, and shipped.

What you will learn

- Learn how to automate repetitive tasks, ensure fixed workflows, and centralize data to facilitate audits from customers and regulators

- Discover how you can achieve end-to-end traceability across your company and suppliers' processes

- See how traceability and repeatability can be set up within CO-AM and other third-party applications

- Realize how a centralized SSOT across a distributed manufacturing network can track data and process workflows (for rapid prototyping and series manufacturing)

Speakers

Craig Johnson

Lara Janse van Vuuren

Julie Miller

Share on:

You might also like

© Copyright Materialise 2026