CASE STUDY

Accelerating Orthopaedic Device Development with Workflow Automation

Most orthopaedic device manufacturers use one of two design philosophies to restore the trochlear groove in such a way that the patella follows its natural pathway during knee movement. Exactech wanted to better understand the native trochlear groove and compare its characteristics to those of common implants, and they needed an efficient way to do it. (Case study presented by Exactech, Inc.)

Industry

Healthcare

Key solutions

Materialise Mimics

ADAM services

The impact

Large study population

Automation of repetitive tasks

Customizable workflow

The challenge

Determine the optimal implant design philosophy

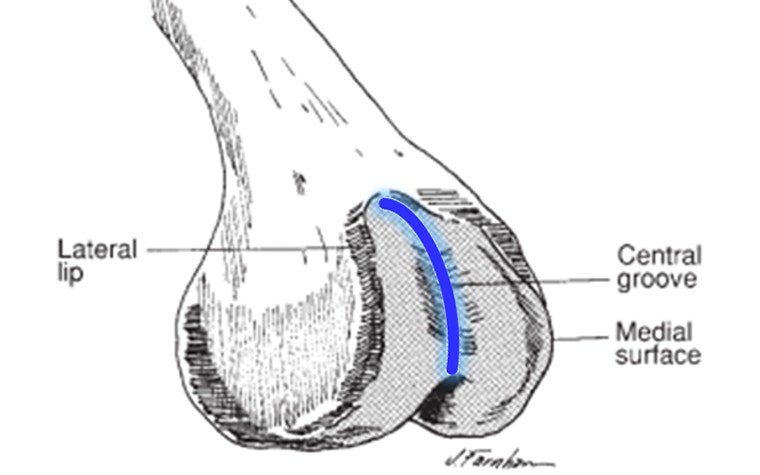

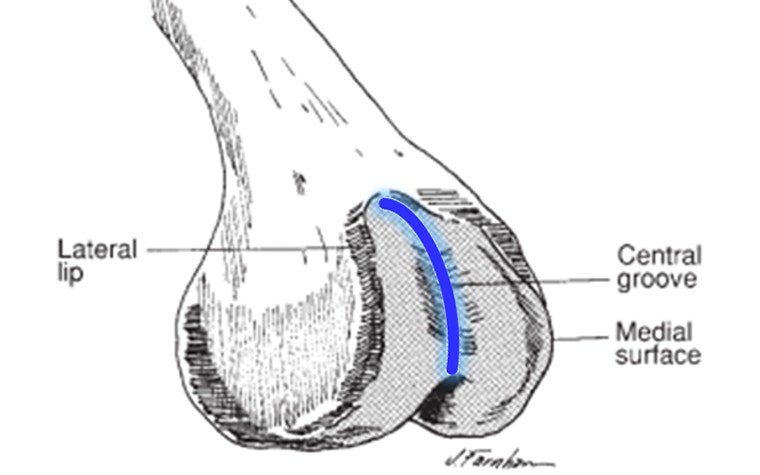

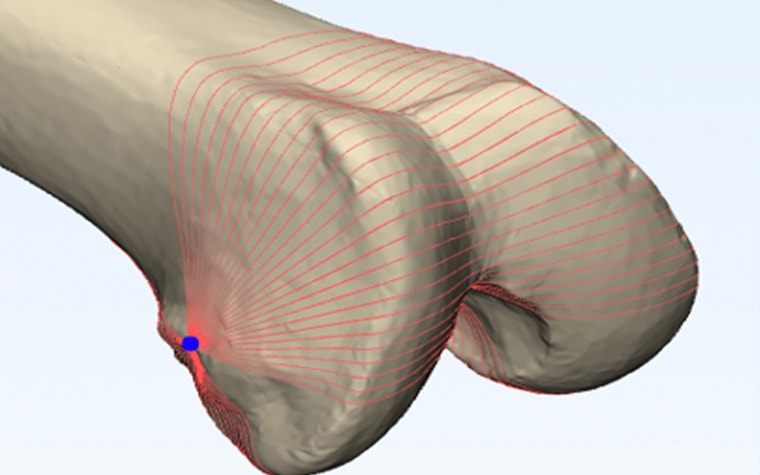

A patellofemoral joint complication is among the leading causes of the failure of primary total knee replacement. In the knee joint, the anterior part of the femur is called the trochlear groove (Figure 1).

When the joint wears down and a total knee replacement surgery is recommended, one of the goals of the femoral component is to restore the trochlear groove in such a way that the patella follows its natural pathway during knee movement.

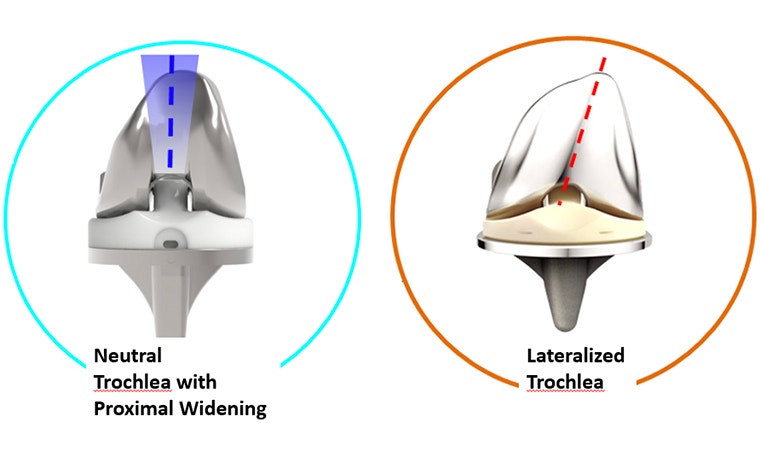

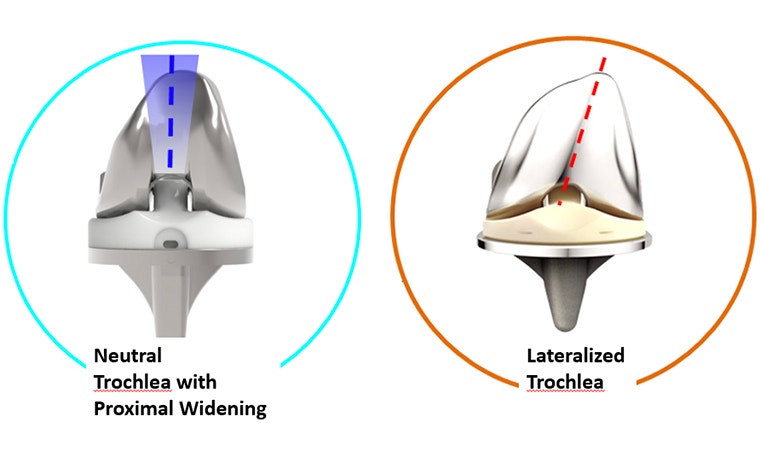

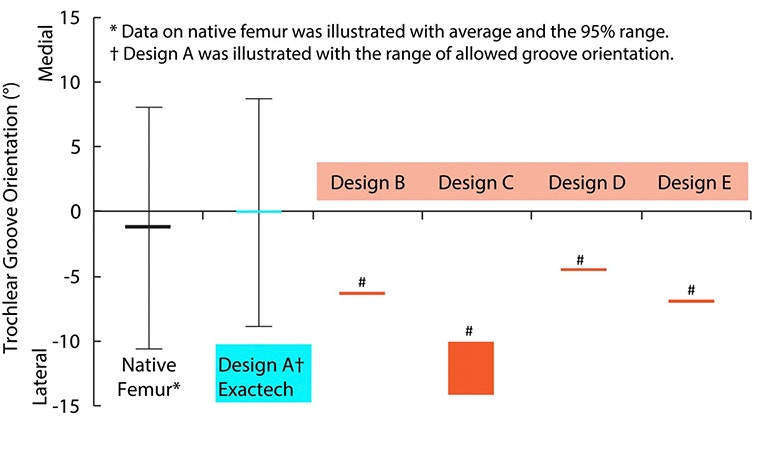

Most orthopaedic device manufacturers address this goal with one of two design philosophies: ‘neutral trochlear groove' or ‘lateralized groove’ (Figure 2).

We (Exactech) performed a study to understand the native, healthy trochlear groove and compare its characteristics to those of implants from both design philosophies. To achieve our study goal, we recognized that a large study population would be needed in order to form a representative sample, as well as an efficient way to analyze the trochlear groove on each of the bones in the population.

The solution

Materialise’s ADAM services and Python scripting in 3-matic

The study started with a database of 94 healthy CT-based femur models previously segmented by Materialise in an Anatomical Data Mining (ADAM) project. The population was chosen to be a mix of 47 males and 47 females, 49 of which were Asian and 45 Caucasian.

Creating each plane in the correct position and calculating the intersection curve manually would have taken well over an hour per bone. Through Python scripting in 3-matic, this task was automatically performed in less than two minutes per bone.

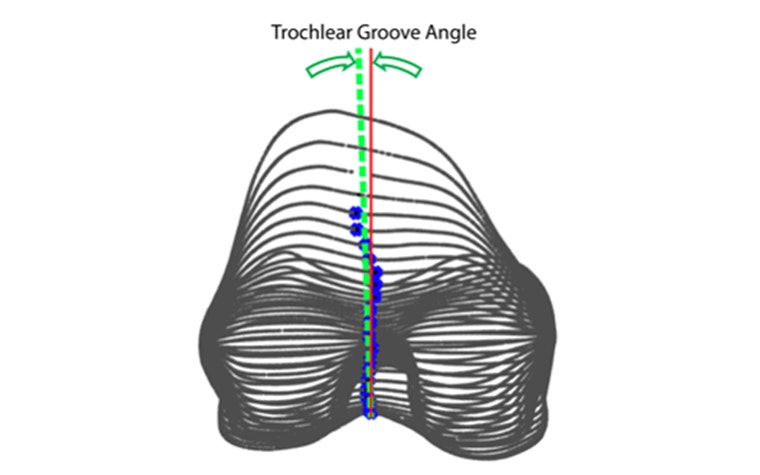

In each of the femur models, an anatomical coordinate system was established based on the mechanical axis. Then, a plane was rotated around the transepicondylar axis in 5° increments (Figure 3). This led to a series of intersection curves between the plane and the distal proximal femur, which reflected the trochlear groove’s M-shape. The lowest points of the intersection curves were used to calculate the trochlear groove angle (Figure 4).

Left: figure 3, right: figure 4

Creating each plane in the correct position and calculating the intersection curve manually would have taken well over an hour per bone, not to mention the room for human error and the tediousness of the work. Through Python scripting in 3-matic, this task was automatically performed in less than two minutes per bone.

As well as working in a highly efficient way that minimized the manpower needed and the chance of human error, the automated workflow developed in this study allowed us to work with a larger study population than would otherwise have been possible, and create a workflow that could easily be expanded and customized for future projects. [Si1]

The result

Cost-effective, population-driven device design

One of the five commonly used implants that were evaluated against the data on the native femur was the Truliant Knee System. This implant follows the neutral groove philosophy with a proximally widened trochlear compartment in order to provide more ‘forgiveness’ to accommodate the naturally varying patella tracking, while the other four knee systems each designed a fixed lateralized trochlear groove angle.

The trochlear groove’s orientation turned out to be on average, neutral, but quite variable within the population, ranging from -10.8° to 8.0° (negative sign indicating lateral tracking of the trochlear groove in the distal to proximal direction). When comparing this to the orientation of the trochlear groove in implants from the two design philosophies mentioned earlier, we (Exactech) observed that the trochlear groove of the implant according to the ‘neutral trochlear groove with proximal widening’ philosophy corresponded very well to that of the study population (Figure 5).

The variation allowed by the implant also matched the natural variation in the study population. This contrasted with the designs that had a lateralized trochlear groove; they tended to deviate laterally from the population.

One of the five commonly used implants that were evaluated against the data on the native femur was the Truliant Knee System. This implant follows the neutral groove philosophy with a proximally widened trochlear compartment in order to provide more ‘forgiveness’ to accommodate the naturally varying patella tracking, while the other four knee systems each designed a fixed lateralized trochlear groove angle.

L-102655-01

Featured products and services

Accelerate your journey to personalization at scale with the most robust software platform for analysis, planning, and design.

Access the power of digital twins while avoiding the steep learning curve with our medical data mining and population analysis services.

Share on: