CASE STUDY

Pioneering Swedish Case Uses Materialise's Personalized Surgical Guides and 3D Planning

In 2011, the very first Swedish surgery with Materialise personalized guides took place in the Sahlgrenska Hospital in Götenborg. Having planned this pioneering surgery using a 3D model based on CT scan data of the teenage patient’s injured forearm, Dr. Peter Axelsson used personalized osteotomy guides to perform the procedure.

The challenge

Restore mobility to the patient’s forearm

Swedish teenager William Göransson broke both legs and wrists in a collision with a motorbike. Two years after the accident, while his left arm had recovered well, he was experiencing limited mobility in his right arm and was unable to do simple tasks like buttoning a shirt.

Dr. Peter Axelsson at Sahlgrenska Hospital in Götenborg wanted to leverage cutting-edge technology to treat the patient and restore his mobility.

The solution

3D planning and personalized osteotomy guides

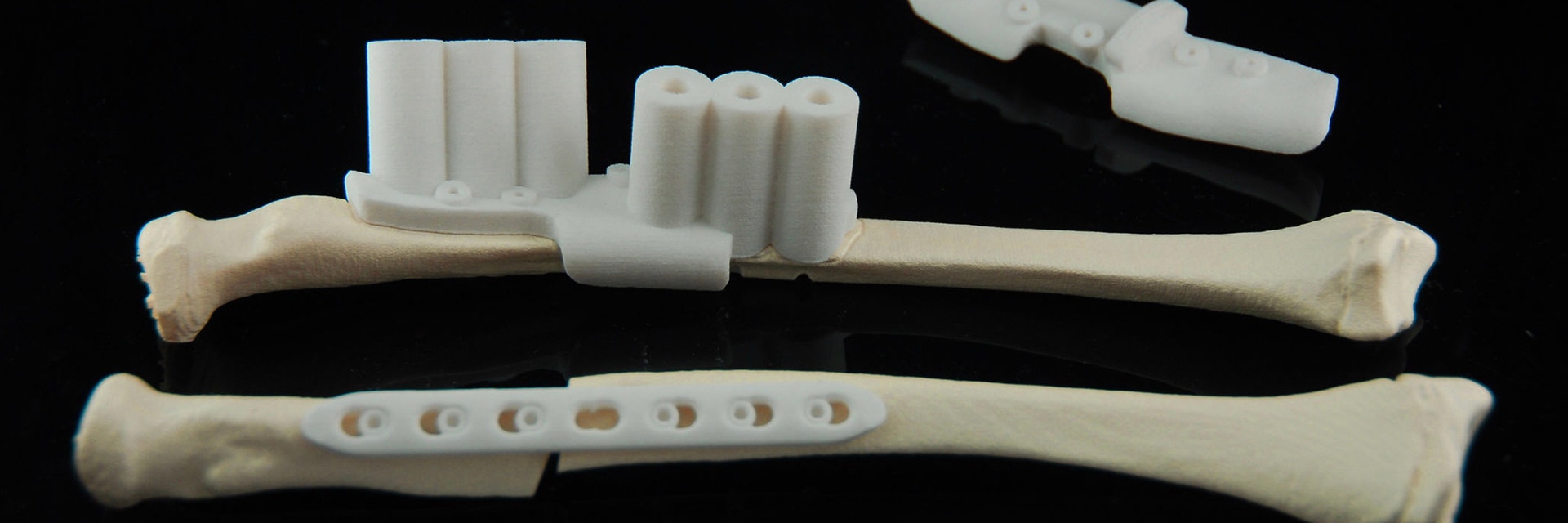

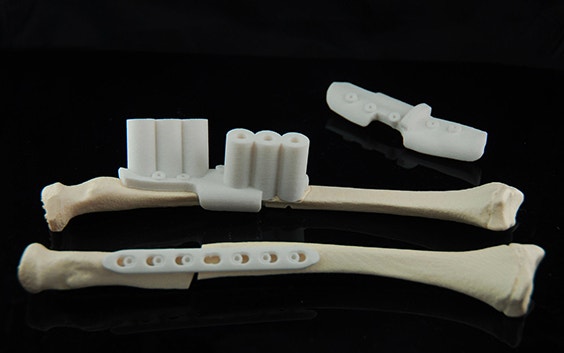

To plan the surgery, CT scans were made of both the injured forearm and the healthy one. Based on the CT images, our clinical engineers made a virtual model displaying the injured and healthy bones. By mirroring the healthy forearm image, doctors could clearly identify the missing bone and determine how the bone originally rotated.

The next stage in the process when using 3D planning and personalized osteotomy guides is a collaborative planning session between the surgeon and a clinical engineer, where the suggested 3D planning is analyzed and the surgical approach validated. Once approved, Materialise engineers proceed with designing and 3D printing the personalized surgical guides to be used intraoperatively to drill or cut according to the 3D planning.

The result

Successful surgery executed to plan

Thanks to the preoperative planning and personalized surgical guides, Dr. Axelsson did not have to take measurements inside the open wound and perform a challenging osteotomy freehand. 3D planning allowed him to anticipate any challenges ahead of time and follow a precise plan to ensure a straightforward procedure.

L-102638 -01

Share on:

This case study in a few words

Healthcare

Materialise Mimics

3D planning and guides for osteotomies

Higher accuracy and predictable patient outcomes

Complex case, challenging to execute freehand