CASE STUDY

Reduce Time to Market and Optimize Orthopaedic Plate Design with CT Scan Data

Standard orthopaedic plating systems do not always match a patient’s anatomy. Prof. Dr. Stockmans used Materialise Mimics to optimize the design of a hand-plating system for an optimal fit through virtual design iterations.

Industry

Healthcare

Key solutions

Materialise Mimics

The impact

Accurate 3D models from imaging data

Population-based design

Reduced time-to-market

The challenge

Improve the traditional hand plate design

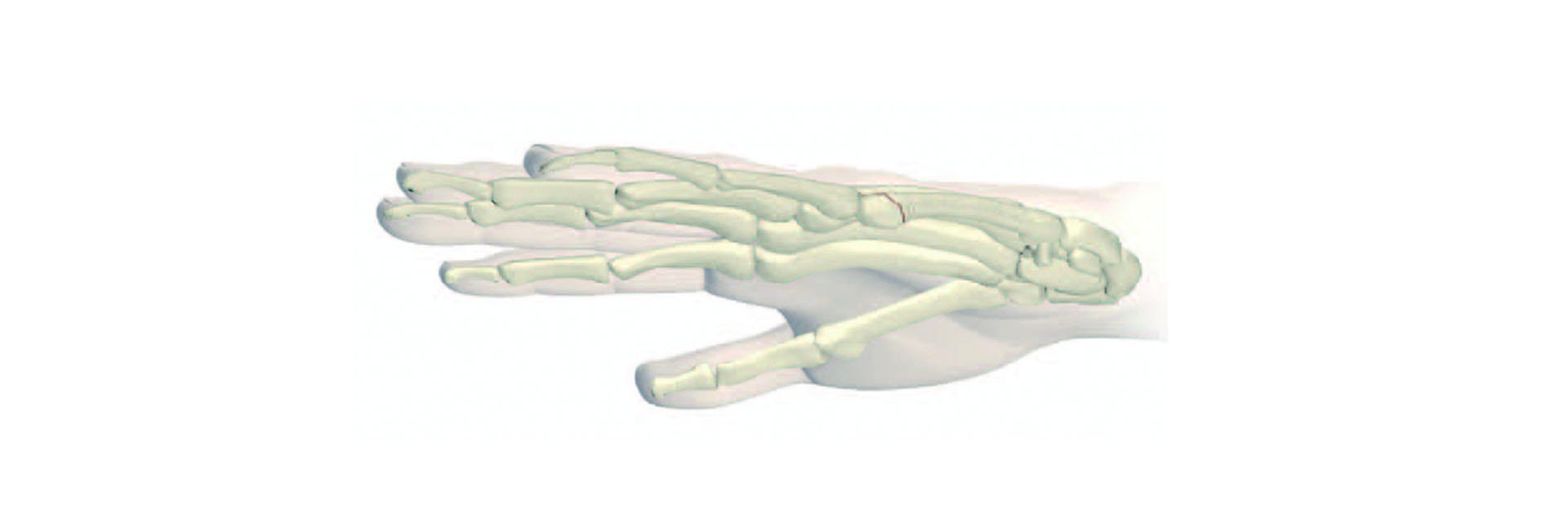

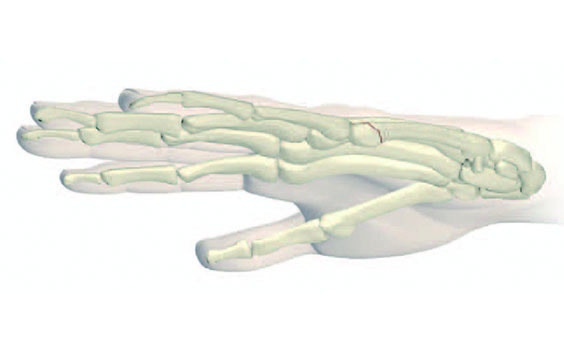

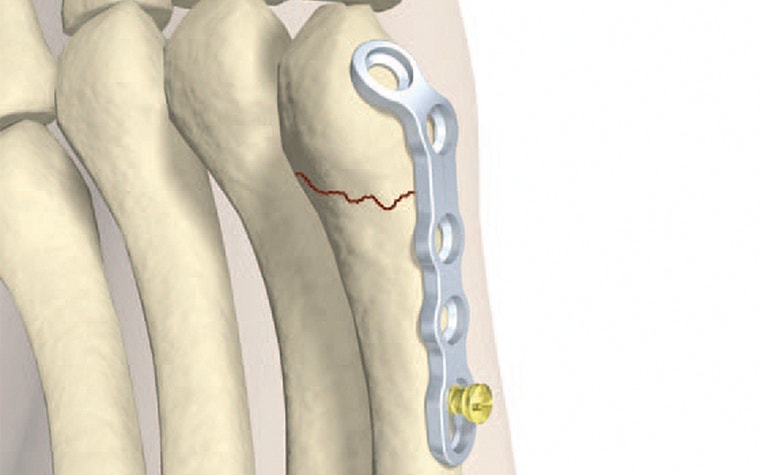

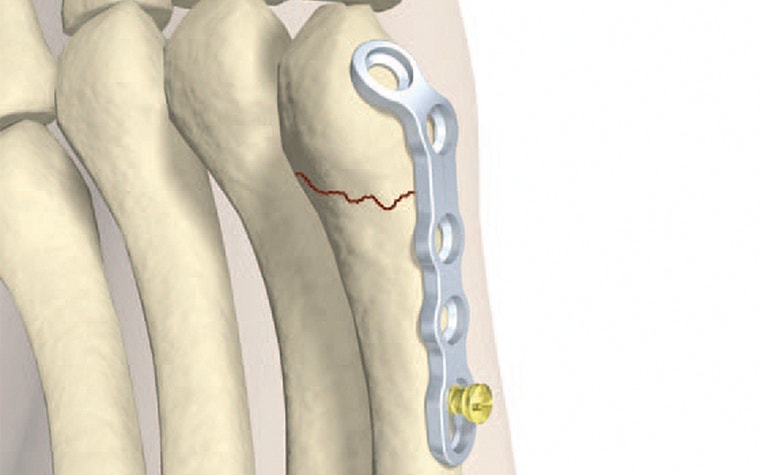

Orthopaedic plating systems currently available on the market to treat bone fractures usually offer standard form plate designs, which don’t always conform to a patient’s anatomy. In the treatment of some periarticular fractures, such as a fracture of the fifth metacarpal bone, this can be rather problematic.

A fracture of the fifth metacarpal bone, which connects the little finger to the wrist, is commonly called a boxer’s fracture because the end of the little finger’s metacarpal bone breaks when bearing the brunt of the impact. To allow the fractured metacarpal to heal, it must be stabilized with a plate.

Traditional hand plating systems offered by orthopaedic device companies did not offer plates with optimal contouring for the treatment of this particular fracture, resulting in unstable anchoring.

Prof. Dr. Stockmans and the medical device company Stryker wanted to address this challenge by designing a new plate with an optimized fit to match the anatomical shape of the fifth metacarpal.

The solution

Population-driven design using CT scan data

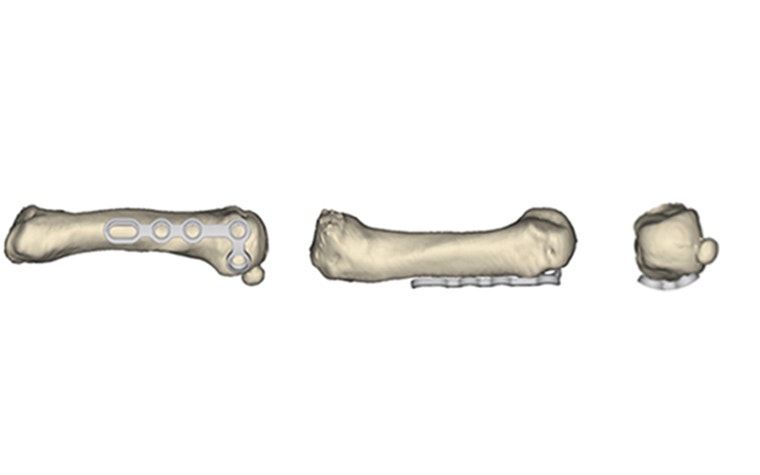

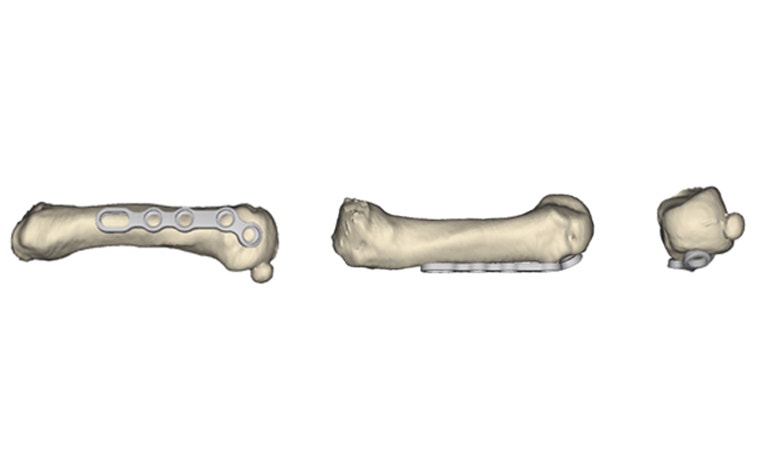

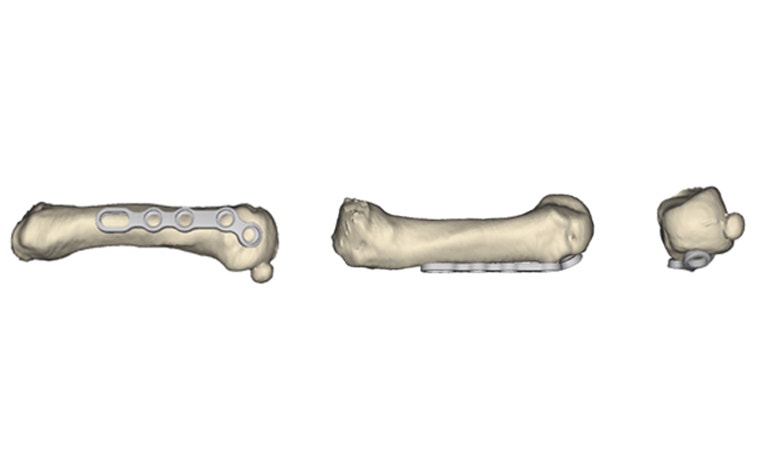

The process began by making highly accurate 3D reconstructions of the fifth metacarpal of multiple patients from their CT scans. The plate was then virtually positioned on the bone and cut into several pieces using the cutting tools available in Mimics.

To attain a perfect fit to the bone, the parts were repositioned and subsequently merged to create a redesigned, anatomically correct metacarpal 5 plate.

In this case study, the authors used Mimics to improve and significantly accelerate plate design by:

- translating CT images into a very accurate 3D model;

- making design changes to the plate to attain a perfect fit to the bone and reduce operation time; and

- virtually verifying the design, thus reducing the time of the design process.

While Prof. Dr. Stockmans’ work used scan data from a limited number of patients, the industry is starting to take this concept to the next level, using not just several scans as design input, but by instead using hundreds or even thousands of scans. This allows engineering teams to gain a thorough understanding of the anatomical variations in a target population and enables them to design devices that maximize patient coverage while ensuring an optimal fit, in a cost-efficient way.

In order to bridge the gap between the large amount of information that is present in image data, and the implant design space, Materialise is offering its anatomical data mining (ADAM) population analysis services. Starting from a large number of scans, we extract the average bone shape as well as population variation models, thus providing medical device companies with a serious head start in the design of their future devices.

The result

A new, anatomically shaped plate on the market within 3 months

Using population-based data to redesign the metacarpal plate gave Prof. Dr. Stockmans confidence that the new design would correctly fit on metacarpal 5 anatomy, resulting in the required immobilization.

Stryker’s design engineers used the improved design from Prof. Dr. Stockmans to develop a final design that met their anatomical and manufacturing criteria. This innovative virtual approach eliminated the need for numerous design iterations and the time-consuming and costly process of producing prototypes for validation and optimization.

Thanks to the availability of patient-specific data and the powerful, user-friendly tools in Mimics, Prof. Dr. Stockmans and Stryker were able to complete the entire process — from concept to market — in less than three months. The process would normally have taken several additional months and would have required numerous prototypes and costly cadaver labs to come to a final design.

The surgical simulation features in Mimics greatly reduced the time-to-market by allowing the team to verify the design and make virtual modifications. The optimized design reduced the operating time by eliminating the need for the surgeons to bend the implant during the surgery.

By combining medical image data with advanced engineering tools, Mimics provides a dedicated platform for surgeons and design engineers to collaborate on the implants of the future. Incorporating feedback from all stakeholders means that surgical procedures and patient outcomes can be greatly improved. The benefits of using medical image data as design input were nicely illustrated through this collaboration between Prof. Dr. Stockmans and Stryker.

L-102656-02

Share on: