CASE STUDY

The New Gold Standard for Jewelry Design Manufacturing with Materialise Software

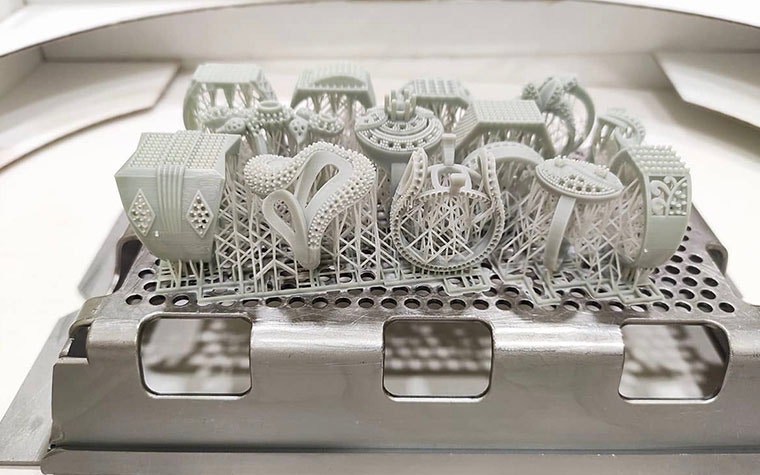

In jewelry design, additive manufacturing (AM) can bring impressive value. Not only does the technology’s freedom of design allow for unique, intricate designs, its production speed also greatly accelerates time to market. But these advantages can only be achieved by making designs printable as efficiently as possible. One of India’s largest jewelry 3D printing companies, Immaculate Creations, encountered challenges here, making scaling their production impossible. So, they turned to specialized 3D printing software.

Industry

Jewelry

Key solutions

Automate data and build preparation with specialized software

The impact

Too much time spent on preparing files for 3D printing

Challenge

Reduce time spent on preparing files

The team at Immaculate Creations used to struggle with preparing their files to be printed in a reasonable amount of time. They noticed that jewelry design programs were not optimized for 3D printing. Designing in these programs resulted in files that were too poor in quality to be sent directly to their 3D printers.

What did this mean for their engineers? Many hours of manual effort to repair and optimize designs before printing. And if a design was sent to a printer with flaws, they dealt with machine crashes that wasted both material and the time needed to reprint. The free software they were previously using didn’t offer an automatic fixing feature tailored for accurately printing high-quality, intricate details on which the jewelry industry depends.

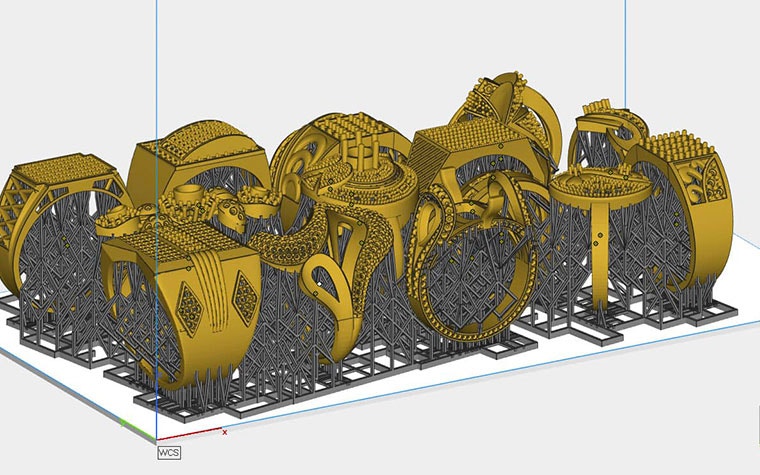

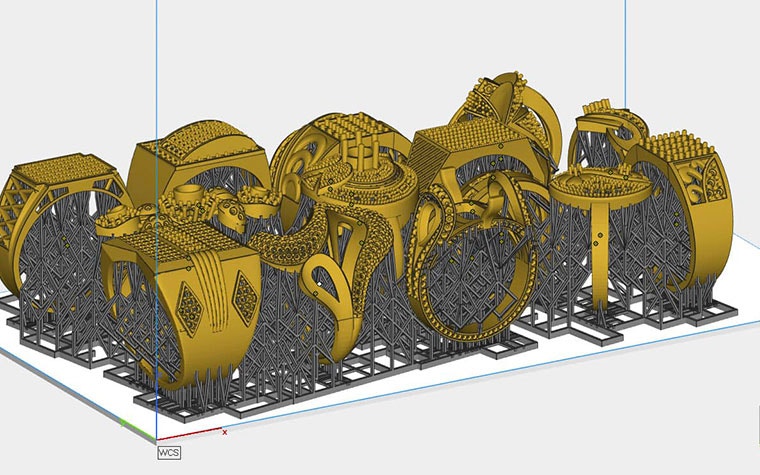

The manual work didn’t end there. Without the right tools, engineers were investing too much of their time into manually adding support structures or tweaking sub-par structures generated by the software that came with their machines.

The downside of this manual work is not only the number of hours lost by the teams but also that the files are usually very large. Complex files are a common problem with 3D printing, and this significantly slows down the process as they take longer to process and slice.

Solution

Automate data and build preparation

The hurdles that Immaculate Creations needed to overcome were clear — minimizing time spent on making design files printable. They concluded that the solution they needed was 3D printing software suitable for jewelry design. And by integrating these solutions into their production, the Immaculate Creations team improved the file preparation process and automated support generation.

“Since introducing these software solutions, we’ve only seen benefits and regret not automating data and build preparation sooner.”

— Immaculate Creations

With Materialise Magics in their workflow, they could easily fix and edit files while keeping the original creative designs intact — they could accurately print exactly what they intended. It also meant that they didn’t have to deal with large file sizes caused by intricate designs anymore. This software enabled a reduction in the number of triangles, thus retaining the same high-quality design with a lighter file weight. Today, 85% of their data fixing can be completed with Magics’ automatic fixing features.

“Using Materialise software has proven to be the best solution for us. Our other options are to hire engineers to manually fix files and optimize the support generation output from OEM software, use free packages that do not meet our quality standards, or export designs through slicer files with low-quality results,” says Immaculate Creations.

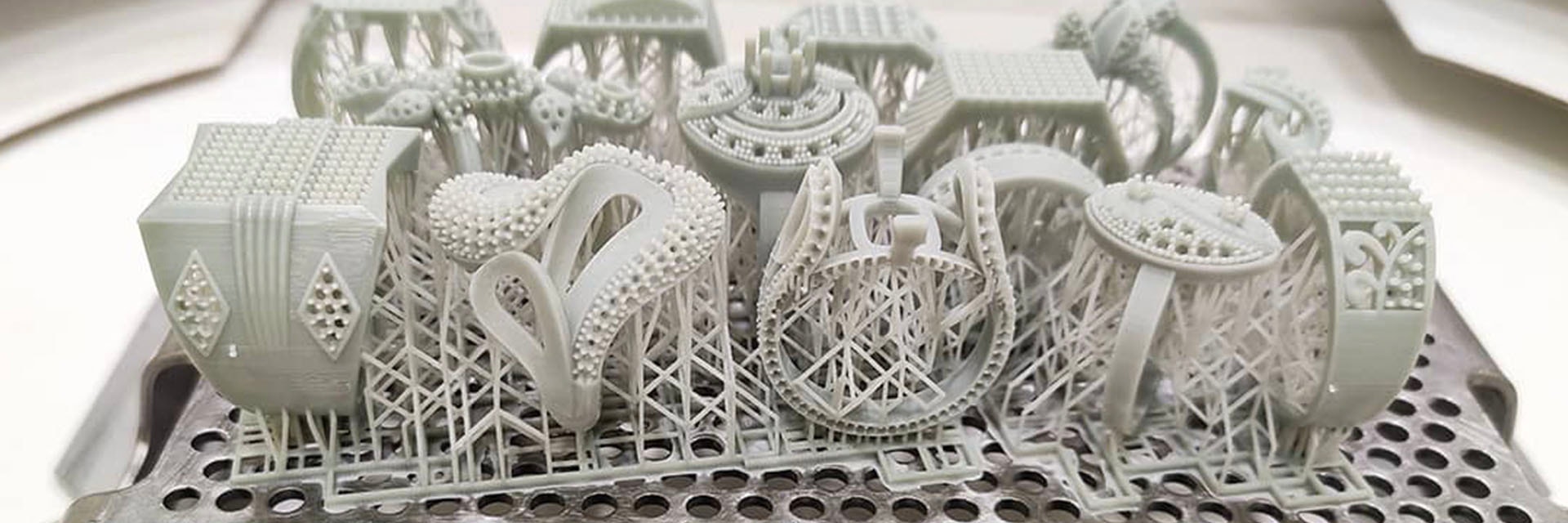

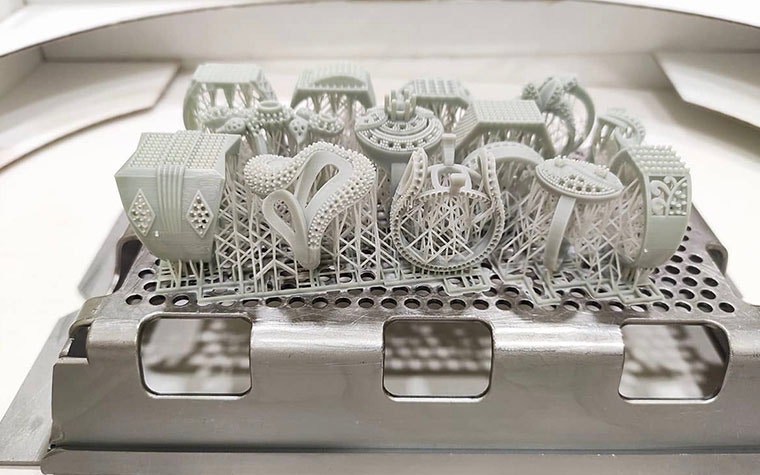

In addition, the team automated support generation with Materialise e-Stage. What previously took the effort of two application engineers could now be completed automatically in a fraction of the time while greatly minimizing human error.

Result

A major increase in production numbers

Thanks to the switch in their software, Immaculate Creations greatly reduced time, effort, and build crashes. Because of this boost of productivity, they were able to quickly scale up. In the five years since they streamlined data prep and build prep, production grew from one machine to ten.

Featured products and services

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Optimize and automate support generation with options tailored to different materials, technologies, and geometries.

Share on: