TRENDS

Five Key Trends for 3D Planning and Printing at the Point of Care in 2025

As 2025 unfolds, 3D planning and printing at the point of care continues to gain traction, moving beyond early adopters into broader clinical practice. The year has already brought significant advancements in automation, AI integration, and operational efficiency, making personalized medicine more accessible and scalable. With reimbursement initiatives gaining momentum, hospitals and clinics increasingly recognize the value of 3D printing not just for patient care. Here are the five key trends shaping 3D planning and printing at the point of care in 2025.

1. 3D planning and printing expands across specialties, with congenital heart disease and oncology gaining momentum

While initially propelled by cranio-maxillofacial and orthopaedic applications, 3D printing is now profoundly impacting multiple specialties. In 2025, congenital heart disease (CHD) and oncology are seeing rapid growth, with more hospitals leveraging patient-specific models for surgical planning and patient education. In CHD, 3D planning reduces ICU time and improves clinicians' abilities to manage potential postoperative problems, while in oncology, personalized surgical guides and radiotherapy devices are improving precision in tumor resections and radiation treatments. As the year progresses, these applications will continue to drive broader adoption across cardiovascular, neurosurgical, and interventional fields.

2. AI and operational efficiency are driving market expansion

In 2025, the evolution of 3D planning and printing at the point of care is not only about clinical impact but also about improving operational efficiency. As hospitals seek to scale their 3D planning and printing capabilities, the need for streamlined workflows, automation, and better software integration has never been greater. Institutions that once relied on external providers for patient-specific models are bringing production in-house, cutting costs, and reducing turnaround times. Consolidating multiple functions into a single workflow is playing a key role in this shift.

A prime example of this transformation is the evolution of Materialise Mimics into a comprehensive platform that integrates AI-enabled segmentation, extended reality (XR), case management, and advanced design tools — all within one system. By centralizing these capabilities, hospitals can manage 3D planning and printing workflows more efficiently, ensuring that they can increase case numbers without compromising quality. These advancements make 3D planning and printing more scalable and sustainable, allowing healthcare providers to expand access to patient-specific solutions while maintaining operational efficiency.

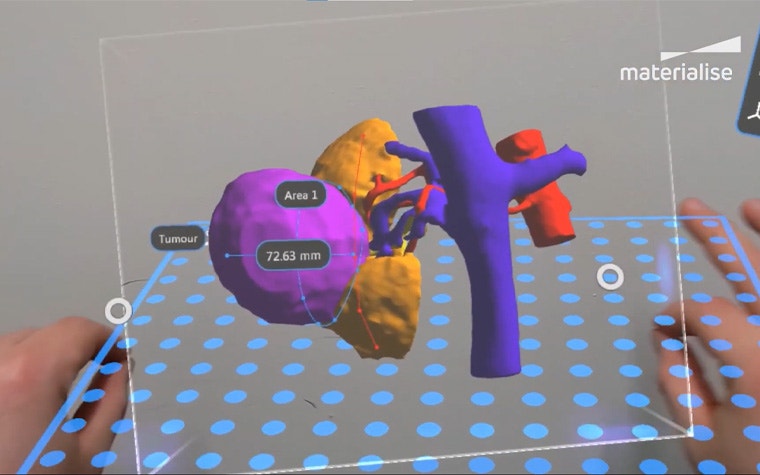

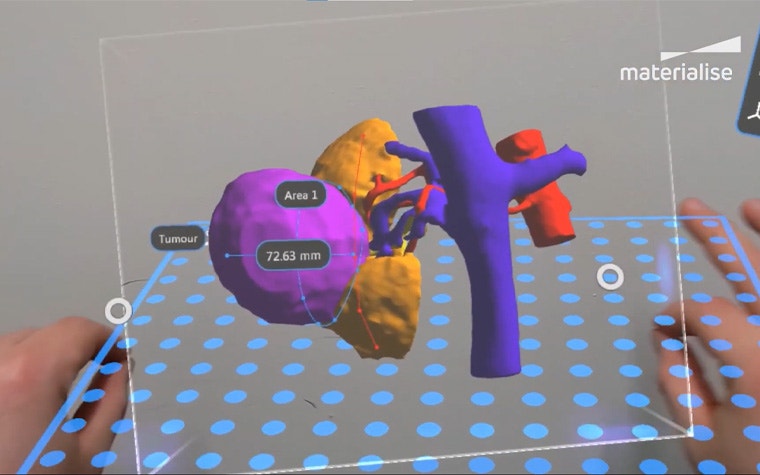

3. Extended reality (XR) is making 3D more accessible and efficient

Extended reality (XR) will continue transforming how clinicians interact with 3D planning, making patient-specific planning faster and more accessible. By using virtual and augmented reality, surgeons can visualize anatomical models digitally, reducing the need for physical prints while gaining critical insights for procedures. This saves time and costs and also expands access to 3D planning for hospitals with limited printing resources. With platforms like Materialise Mimics, clinicians can seamlessly transition from segmentation to an interactive, immersive environment, streamlining workflows and enhancing collaboration across medical teams.

4. Reimbursement is becoming a reality

One of the most significant shifts in 2025 is the progress in reimbursement policies for 3D medical models and 3D-printed devices. While coverage has historically been limited, insurers have begun recognizing the cost benefits of 3D planning and printing. Standardized coding structures are making it easier for hospitals to submit claims, and several independent programs are setting the stage for broader reimbursement in the coming months. If this trend continues, the second half of 2025 could mark a turning point where financial barriers to adoption are significantly lowered.

5. Hospitals are strengthening quality and regulatory compliance

As 3D planning and printing becomes an established part of clinical workflows, hospitals are taking proactive steps to ensure compliance with existing regulatory frameworks. This is driven by the growing recognition that maintaining compliance is essential for scaling point of care 3D planning and printing and integrating it into routine medical practice.

Hospitals are increasingly adopting robust quality management systems (QMS) to standardize processes and ensure that every 3D model or 3D-printed device meets regulatory expectations. Rather than navigating compliance as an afterthought, institutions are embedding it into their workflows from the start, making regulatory adherence more seamless. Software solutions such as Materialise Mimics Flow — are helping hospitals document their case processes and achieve greater efficiency. As more hospitals successfully implement these systems, 3D planning and printing at the point of care is becoming more scalable, with clear pathways for ensuring patient safety while expanding access to personalized medical solutions.

The road ahead in 2025

With expanding clinical applications and increasing operational efficiency, 3D planning and printing at the point of care is moving from an innovative tool to an indispensable part of modern healthcare. As regulatory and reimbursement frameworks evolve, we can expect even more hospitals to invest in scalable, integrated 3D planning and printing solutions. The rest of 2025 will likely see further breakthroughs in accessibility and efficiency, cementing 3D planning and printing as a standard of care in personalized medicine.

L-104573-01

Materialise medical device software may not be available in all markets because product availability is subject to the regulatory and/ or medical practices in individual markets. Please contact your Materialise representative if you have questions about the availability of Materialise medical device software in your area.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.