EXPERT INSIGHT

Spine Care Innovation — 5 Ways Personalization Sets You Apart

The five biggest spine companies are generating 66% of the spine market revenue, leaving dozens of competitors striving to distinguish themselves and stand out from the crowd. This article explores how innovative spine companies deliver unique patient value by leveraging personalization and 3D technologies.

1. Adding value with 3D virtual surgical plans that build confidence

Today’s surgeons have access to more tools than ever before to facilitate preoperative planning for deformity correction. However, time constraints often prevent them from dedicating ample time to this important step.

To address this, spine companies add value to their existing standard portfolio by delivering suggested preoperative plans to busy surgeons and offering them a significant head start in a multidisciplinary effort to help the patients.

Clinical engineers from spine companies possess unparalleled knowledge of their devices and can offer valuable suggestions to surgeons: screw length, ideal entry angle, depth of insertion, implant type, size, etc. By leveraging historical data, literature review, and surgeons’ preferences, spine companies adapt to both the patients and the surgeons.

Finally, simulating the procedures in a virtual environment is risk-free, helping to minimize intra-op surprises and increase clinicians’ confidence.

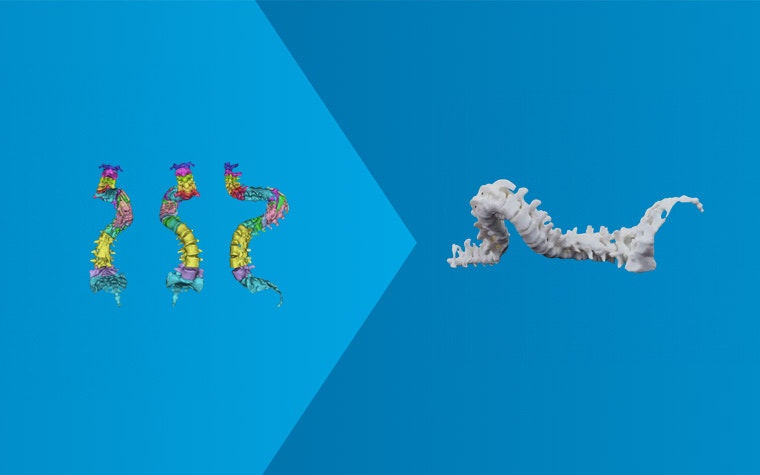

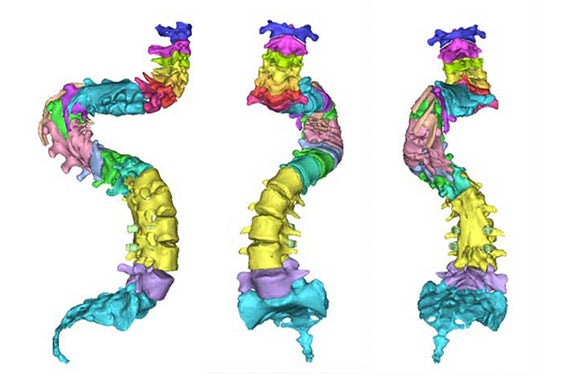

Left: Zoé Maldonado’s spine reconstruction using Mimics Medical for preoperative planning. Right: Anatomical model printed with Stratasys

2. Manufacturing 3D-printed anatomical models to provide unique insights

3D-printed models can improve communication and patients' understanding of their spinal disorders and the planned surgical intervention to address the issue, thus reassuring them. Given the spine's intricate structure and the significant risks associated with spinal surgery, life-size 3D-printed models of deformities can shed new light on a patient’s condition and contribute to preoperative planning. 3D-printed models can also be used (or reused) to train students.

The story of Zoé Maldonado, a 14-year-old girl with severe idiopathic scoliosis, exemplifies the transformative power of 3D technologies. These innovations enabled Dr. Vilchis and his team to communicate and collaborate on what was considered an inoperable surgery. The team affirmed that without the use of 3D-printed models and advanced imaging, the successful outcome would not have been possible.

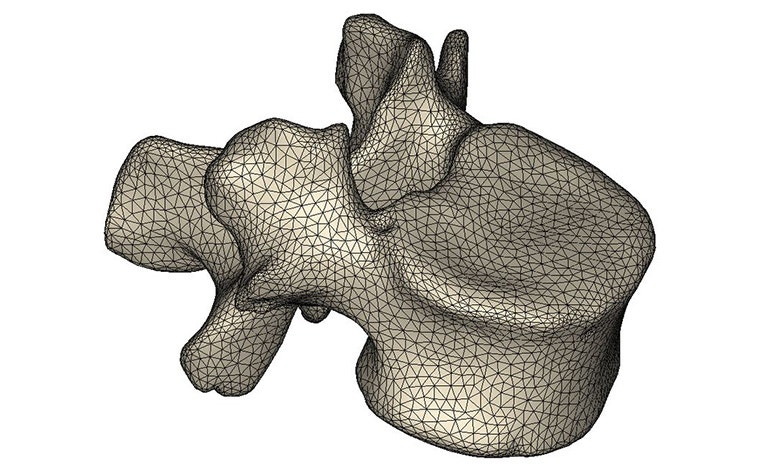

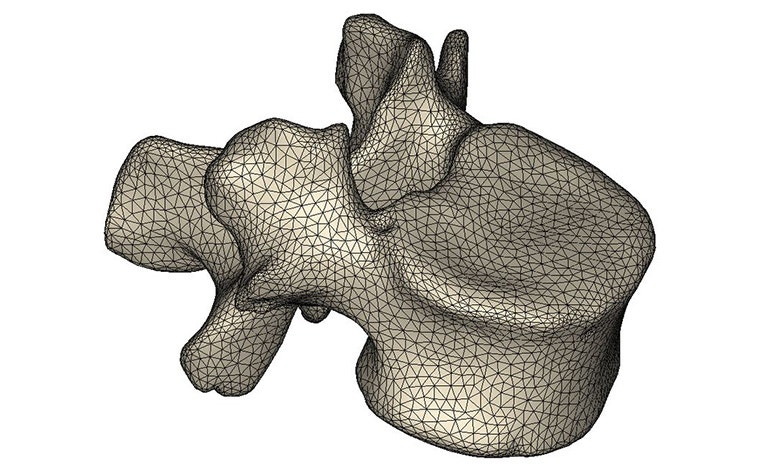

3. Offer patient-specific instruments to precisely execute the surgical plan

While traditional fluoroscopy-based navigation brings a lot of value, it might not be accessible everywhere and exposes patients to radiation. In this context, patient-specific guides are an enabling technology that offers an accessible alternative to deliver precise, fast, and cost-effective.

A systematic review from Yu et al. of 13 studies, including 446 patients, concluded that 3D-printed drill guides can improve the accuracy rate of pedicle screw placement, shorten operative time, and reduce intraoperative blood loss.

As a spine company, you can design patient-specific guides based on 3D reconstruction from CT images, as illustrated by Mediimplantes in this interview.

4. Develop and design patient-specific implants to match the patient’s unique anatomy

Patient-specific implants are emerging as a transformative innovation in spinal surgery.

Experts believe personalized implants tailored to meet individual patient requirements and specific anatomical considerations will reshape the spinal landscape when considering the potential benefits: improvements to the implant-bone interface and improved patient and surgical outcomes.

Numerous surgeons and medical device companies, like 3D Morphic from Australia, are already pioneering this approach. The agile and on-demand aspect of such solutions is challenging the traditional implant manufacturing and delivery value chain.

This trend is gaining traction not only among early adopters and innovators but also within regulatory bodies and payers. The FDA has granted two Breakthrough Device Designations for Carlsmed®’s aprevo technology, patient-specific interbody devices for the correction of adult spinal deformity. Moreover, the Center for Medicare & Medicaid Services (CMS) will grant aprevo® the highest level of the new spinal fusion Medicare Severity-Diagnosis Related Groups (MS-DRGs) created. The new assignments and payment rates are favorable and will go into effect on October 1, 2024, signaling a broader acceptance of personalized spinal implants.

5. Leverage personalized insights to streamline the R&D process

Spine companies can harness personalized insights throughout the different steps of their R&D process. R&D teams can analyze their population based on large batches of CT or MRI scans and better understand their targeted patients. This information can then be used as a reliable source for design input.

Next, 3D technologies can be leveraged during pre-clinical in silico testing by creating realistic virtual patients to test implantation and biomechanical outcomes. The virtual patients can be specific (based on scans of unique real patients) or synthetic (based on statistical shape modeling) and help pinpoint potential device failure early in the development process.

Why does it matter now?

The software landscape has been quickly evolving in recent years. Previously, creating spine 3D models was a tedious and manual task. AI-enabled algorithms and semi-automated tools reduce manual effort, optimizing time and resources as a result. Those 3D models serve as a foundational step in the solutions described above.

The design process can also benefit from automation and a little help from AI to drastically decrease working hours, cost, and lead times.

In conclusion, adopting personalized solutions in spinal care has become increasingly feasible, providing significant opportunities for differentiation in the field. By utilizing advanced insights and 3D technologies, companies can develop patient-specific treatments that not only improve clinical outcomes but also contribute to the advancement of personalized medicine.

While the significant potential of the clinical applications described below is evident in the literature, more quality long-term data needs to be collected to generalize their use.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.