INTERVIEW

Innovative Advances for the Treatment of Complex Spinal Pathologies: Cutting-Edge Tools for Enhanced Quality of Life

More and more companies are offering highly efficient solutions to improve patient care. Because of this shift towards personalized medicine, many standard medical device companies are expanding their portfolios. In this conversation with the team from Mediimplantes — a Colombian company dedicated to designing, manufacturing, and distributing spinal implants — we discuss their decision to level up their offering now that 3D technology is growing and becoming a benchmark in the market.

What made you confident to take on this challenge of customizing your portfolio?

Orielson Cruz, Development Director, Mediimplantes: As soon as we learned that diagnostic images can be converted into accurate 3D models of the patient's anatomy, the path forward was clear.

Our starting point was a complex case that came into our hands through a partner in El Salvador. That’s when we began looking for alternatives outside the traditional methods. This was the first step in our personalized medicine journey, and it motivated us to continue exploring because, up to that point, no one in the region had dared to do anything similar for the spine. In 2022, we decided to formally develop a case alongside a surgeon.

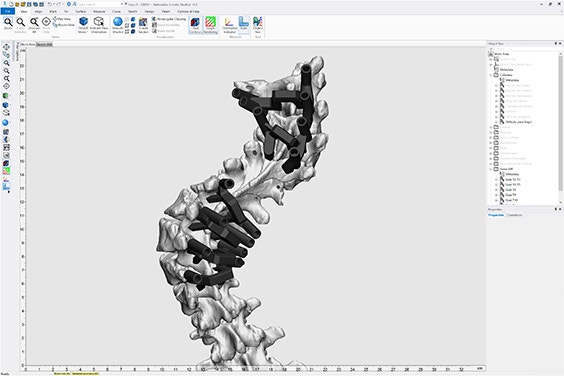

We investigated different software tools and chose Materialise Mimics after testing it out and getting support from Materialise engineers. Reviewing the literature, you can see that companies in Europe and the US are quite advanced in this field, and their success proves the effectiveness of these tools.

“No surgeon has backed out after seeing a 3D reconstruction.”

— Orielson Cruz, Development Director, Mediimplantes

Which case was the most impactful, and what were the results?

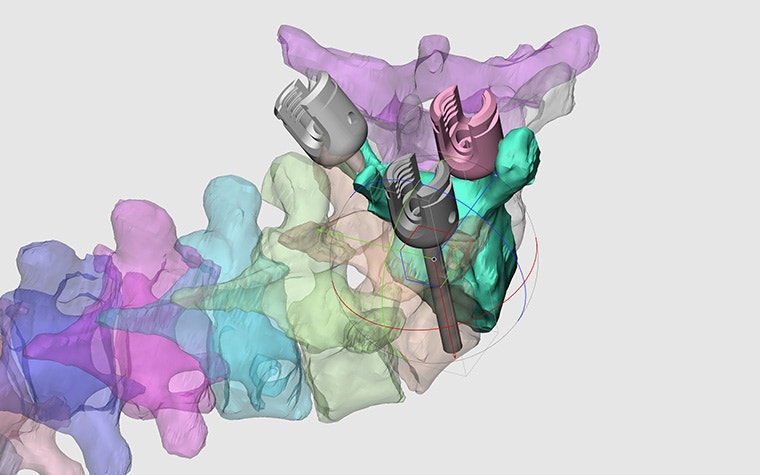

Cruz: The most impactful case was a girl with a severe spine deformity. She already had several operations and needed a more permanent solution. When we had the opportunity to digitize her spine and review it in depth with the surgeons, it changed the course of things. We could see what wasn’t visible before. The power of this data is clear: in all of our cases, no surgeon has backed out after seeing a 3D reconstruction.

For this case, we printed personalized guides to easily place the pedicle screws. They worked very well, and even the surgeons considered them as tools that could change the future of medicine. And most importantly, the surgery resulted in an excellent correction for the patient.

Beyond this, we have to emphasize the great confidence that the surgeon had in us. For this operation, we selected the screws and designed the pedicle grasping. It was the first time the surgeons permitted someone else to play such a fundamental role in their surgical workflow. This multidisciplinary collaboration was revolutionary and innovative for them, and they said it could enable more surgeons to operate on cases that don't appear in the literature. Now, we can see the vertebrae very well, look at pedicles that are not suitable for screw insertion, and simulate and design whatever we want without the biological risk of doing so while the patient is exposed.

Additionally, Daniel Ruiz, the Materialise engineer who worked with us, gave us clear guidance and continues supporting us with the software. It’s with his help that we’re able to develop such innovative products that promote our growth and improve our position in the market.

Courtesy of Mediimplantes: Segmentation, design, and impression of the guides and spine model with Mimics

“If the segmentation doesn't look good, the design won't look good — so the tool you use to segment makes a significant difference.”

— Wilmer Barrera, Design Coordinator, Mediimplantes

How did Materialise's involvement support these cases?

Wilmer Barrera, Design Coordinator: I remember when I tried Materialise software for the first time. I had already tried free tools, so the difference in speed, ease of design, and accuracy for complex segmentation was vast. If the segmentation doesn't look good, the design won't look good — so the tool you use to segment makes a significant difference.

Daniel Correa, Senior Designer: Since we started with Mimics, we’ve felt supported. The Materialise team clarifies any doubts and concerns we have almost immediately and constantly shares advice.

We started this offering from scratch and will work through several phases to reach our ultimate goal. We’re currently in the first phase, providing surgical support but not yet manufacturing implants. This personalized approach is revolutionizing highly complex surgeries, which previously represented enormous risks and generated uncertainty for the surgeon because the traditional techniques were not reliable enough.

With the tools we use now, we’re reducing surgical times, blood loss, radiation, and many other inconveniences. Every case we have handled has been a huge victory, as if it were the final of the World Cup. We are very happy to be able to give patients with serious problems another chance to live life to its fullest. And the technical support we’ve received from Materialise for each new challenge we take on has been irreplaceable.

How do you see the personalized implant market in Latin America today? Is it worth continuing to bet on personalized medicine?

Cruz: We see no limit to it. I think the biggest barrier will be gaining funding and total acceptance from hospitals. Institutions must rely on this technology and trust the experts who design and manufacture it.

It is incredible to know that with only Mimics and a metal or PEEK printer, you can not only design and deliver a product but also develop real solutions for complex cases.

In Latin America, there are a lot of very complex clinical cases, and we think this technology is only used half of the time. There is still a lot to explore. At the moment, we have limitations with manufacturing implants, but that does not prevent us from proposing and creating innovative solutions from the design and planning stage. We can imagine and create with the surgeon while the patient is at ease at home.

What do you see for the future of Mediimplantes?

Cruz: We want to strengthen our position as experts in solutions for highly complex spine cases. However, we are also venturing into planning and design for cranioplasty cases.

We strongly believe in the safety and technical feasibility of the technology, so we are investing time and resources into developing and printing new products for highly complex cases, even in the cranio-maxillofacial area. The best thing about this is that the possibilities are endless, and we are ready to make the most of our resources. We’re confident we’ll overcome every challenge and continue spreading personalized medicine throughout Latin America.

L-103541-01

Share on:

Biography

Orielson Cruz

Biography

Wilmer Barrera

Biography

Daniel Correa

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.