EXPERT INSIGHT

Reduce and Rethink: How to Take a Proactive Approach to Waste Reduction with Additive Manufacturing

Additive manufacturing has come a long way since its early days. Thanks to design innovation, mass customization, and on-demand manufacturing, AM brings many benefits to both small and large companies across various industries. Businesses can launch products to market faster with fewer investments, responding to customer needs swiftly.

But where does AM stand on environmental impact? Does it produce less waste than traditional manufacturing technologies?

Considering most traditional manufacturing techniques are subtractive, leaving a lot of scrap material behind, AM is a great alternative. 3D-printed products are designed without molds, so they require less material, which means less waste. This way, businesses can cut down on what they throw away, strengthen the circular economy, and create more sustainable manufacturing resources.

Committed to waste reduction

Unfortunately, sustainability has become something of a buzzword that companies seem to ping pong across their communication channels. It is a far more complex concept that needs proper understanding and a high level of commitment. Since our humble beginnings, we have been focused on contributing to a better and healthier world, thinking about generations to come. As Fried Vancraen, CEO at Materialise, explains: “Sustainability is about meeting the real needs of the present generation without compromising the ability of future generations to meet their needs.”

Considering there aren’t many insights about the full impact of AM on the environment and the people, we are committed to further investigating the consequences of this technology. Over the last few years, we have expanded our sustainability objectives and raised awareness about the importance of research.

We defined the key goals to reach by 2025 and are taking actionable steps that align with our long-term strategy. By asking questions like “What can we do to make AM more sustainable?” and “How can AM be applied as the most sustainable choice?” we are seeking new ways to design and create solutions that will empower ourselves and our customers to be more sustainable.

“Materialise is committed to investing in additive manufacturing knowledge, so we can empower our customers and partners to make the right choices for a sustainable future. This information is essential to avoid greenwashing and to focus on the right kinds of innovations and to start having a real impact,” explains Fried.

Sustainability starts with understanding our environmental impact

A life cycle analysis, or LCA, is a method used to assess the environmental impact in every stage of a commercial product — from the extraction of the raw material through the manufacturing process. The higher this cycle is the lower the environmental impact. In this sense, 3D-printed products are potentially more beneficial. Additive manufacturing is based on isolated parts, which extends the life cycle of that product. This allows the addition of new components or the improvement of existing ones, which optimizes and extends the life of the original product. Several aspects related to the lifecycle are also considered, such as the possibility of creating lighter parts that affect the use of the object, such as fuel consumption and the emissions it causes.

To better understand the impact of our technology and confirm this assumption, Materialise conducted a life cycle analysis to look at the environmental impact of producing one million pairs of midsoles. Together with our partner BASF, we compared three AM technologies with a conventional manufacturing technology: conventional PolyUrethane casting.

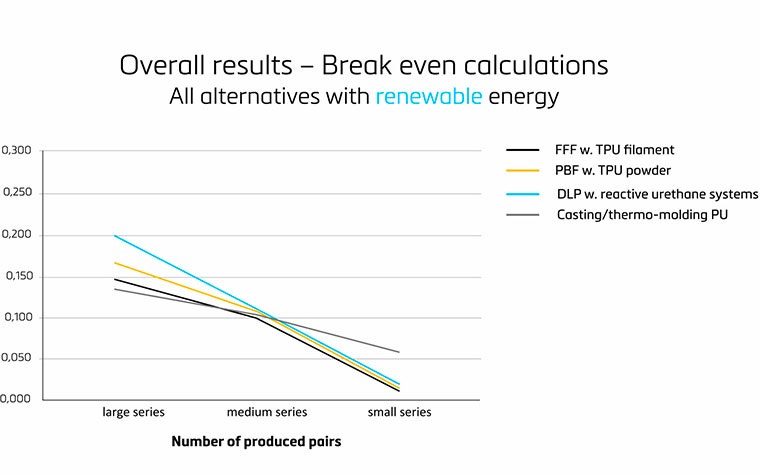

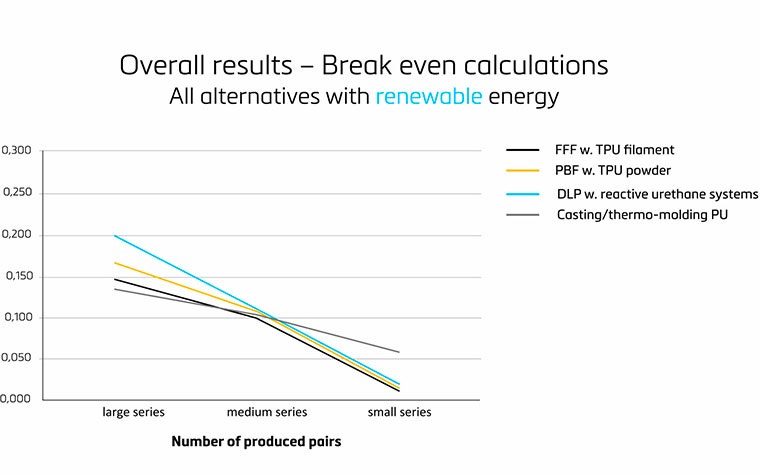

At what point does AM become the suitable choice? If we start decreasing the series size, we see things turning in favor of the AM alternatives. Each time we make the process a bit more energy efficient or consume fewer materials, we move the tipping point in the right direction. It’s important to mention how the tipping point can be very different, depending on the types of parts, but in general, the smaller the amount, the higher the tipping point.

The main conclusion of the LCA research is that we cannot argue that AM is more sustainable than traditional manufacturing technologies. AM is not the definitively more sustainable choice. In some cases, it has a worse impact on carbon footprint. However, on some occasions and for specific applications, AM can offer a more sustainable option. This heavily depends on the overall business model considering materials, transport, energy consumption, resources, processes, etc. With the example of the insoles, we can integrate the midsole with the insole in one customized piece, and by doing so, we can reduce the impact while increasing the value.

"In general, for small series, the chances of producing more sustainably with AM will be greater, but then, of course, we need the tools to make those small series cost-effective and with minimal scrap. In this context, we will also announce some innovations today to reduce logistics costs. Still, more critically needed are multiple new products that enable us to reduce the scrap and waste in general," says Fried.

Bluesint and Quality & Process Control: Delivering a promise, making a difference

As the results of our LCA study show, producing with AM can be more sustainable for small-to-medium series, but it demands the application of suitable tools that can build the small series cost-effectively with less scrap.

By conducting our research and intensive studies, we want to find new ways to recycle and reduce waste and ultimately eliminate it.

As Fried explains, “We need to innovate beyond reducing waste and create a path towards eliminating waste." To deliver this promise, we have two innovative solutions that eliminate waste and speed up the manufacturing process. Bluesint PA 12 and the Materialise Quality & Process Control (QPC) software system help companies reduce their impact on the environment. These tools are part of our plan to build a line of products that are focused on sustainability.

About Bluesint: 3D printing with re-used powder

Laser sintering is a popular method for 3D printing. For each build with traditional laser sintering, about 50% of the unsintered powder becomes waste.

With Bluesint PA 12, we can use more of the already-sintered powder in the mix to build brand-new parts. This innovative technology can reduce carbon emissions by about 30% — more than any alternative currently on the market.

About Quality & Process Control: Ensure repeatability and demonstrate process stability throughout your AM workflows

More than 80% of manufacturers already use AM in their factories today, but mainly for prototyping and in their innovation centers. When adopting AM for large-scale production, companies are reluctant to execute it since they believe it’s too expensive, too complex, and too time-consuming. Our main question was: “How can we help companies scale up their operations in a sustainable way?”

Quality & Process Control (QPC) is a secure, collaborative, and open software system that allows manufacturing companies, service bureaus, and machine builders to transform AM process monitoring and quality data into actionable insights using AI and IIoT connectivity. With QPC, they can get your process under control by tracking and monitoring the accuracy of the production process across repeated experiments to ensure manufacturing repeatability.

Plus, the system gives them the ability to take advantage of AI-powered Layer Analysis for metal AM, helping quantify defects and identify root causes based on correlated data across the process chain. As a single source of truth, QPC helps businesses enhance team collaboration, optimize operator efficiency, improve machine uptime, and deepen their workforce’s understanding of the AM process to boost productivity and support sustainable 3D printing.

Unchartered territory waiting to be discovered

There is still much to learn, and nobody can predict the future of AM. Its high potential lies in limitless possibilities we still need to discover. But one thing is certain; it’s up to us to stretch our minds and reveal more ways that AM can help us build a more sustainable business and create a positive impact in the world.

“3D printing has been used in a production context for barely 20 years. So, there are still plenty of innovations to be done. Let’s make them meaningful,” concludes Fried. "Materialise is committed to investing in the additive manufacturing knowledge, so we can empower our customers and partners to make the right choices for a sustainable future."

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.