EXPERT INSIGHT

How RapidFit Is Mastering the Automotive Tooling Value Chain

In a market that’s no stranger to rapidly shrinking development cycles and technological leapfrogs, the digitization of manufacturing is an immediate necessity. Driving that need are industry demands for continuously improving lead times and quality standards. So what does the factory of the future look like for automotive tooling?

RapidFit, Materialise’s automotive tooling division, works with the world’s top automotive brands and parts suppliers. Managing Director Filip Dehing believes that the factory of the future will be built on two key principles: mastering the complete value chain, and doing so digitally.

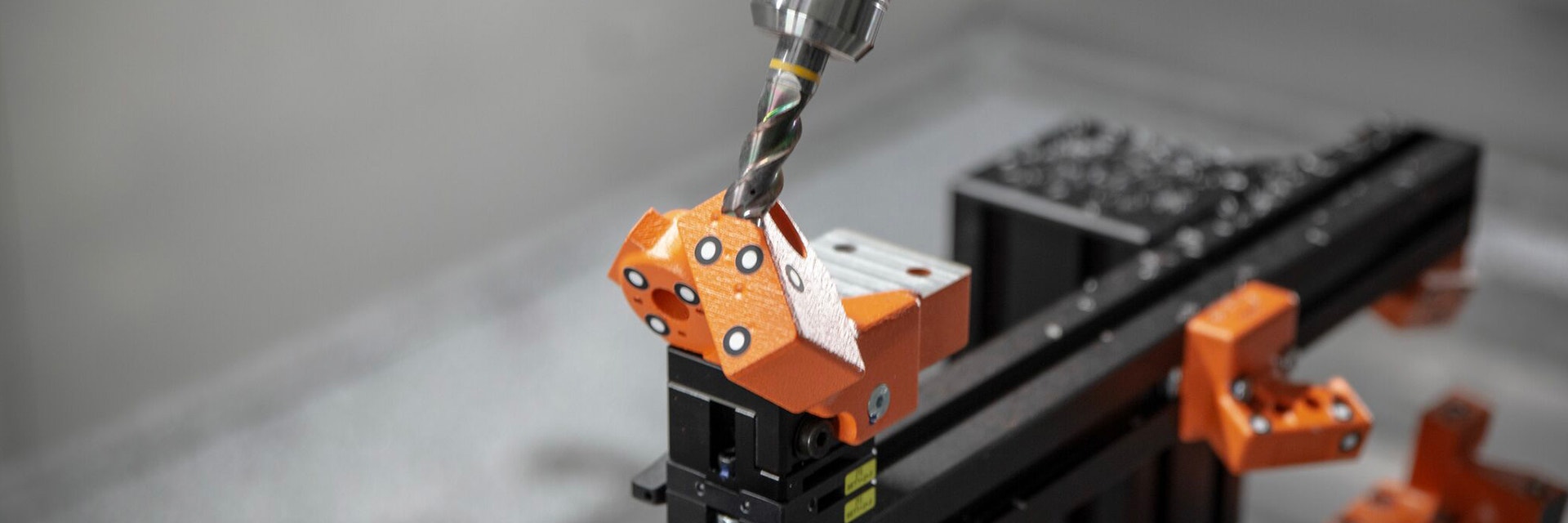

And that’s exactly what he’s doing with a recent addition to RapidFit’s high-tech workshop: a large-format 5-axis CNC milling machine, big enough for even cubing projects — quality inspection tools the size of an entire car — combined with Siemens NX CAM software running together with the CAD environment.

Quality and lead times, driving upgrades

Today, RapidFit’s product lines include cubes, quality and measurement fixtures, and production jigs, using 3D-printed components to leverage the technology’s nature of on-demand production and weight-efficient design.

Every project at RapidFit is bespoke. Yet, the workflow is as standardized as possible. Using software-driven design automation, RapidFit has produced a parametric library of template designs that enable it to drastically shorten the design process. That’s just one of the examples that show the top requirements of the highly competitive automotive industry: fast lead-times, high quality, and consistent reliability.

“In the vision of Industry 4.0, your data flow has to master your production flow. By bringing more elements in-house, from CAD design to CNC programming, we’re making our backbone of services complete. ”

— Filip Dehing, Managing Director at RapidFit

Tools like quality fixtures are used by automotive brands to measure precision during quality analysis, but the tools themselves are equally subject to standards of precision. RapidFit’s workshop already featured three Coordinate Measuring Machines, housed in a top-notch temperature-controlled metrology lab, measuring at up to 7 microns accuracy. The addition of the Zimmermann FZ33 5-axis milling machine, enables RapidFit to manage the CNC programming and milling of their jigs and fixtures in-house.

Computer-aided design to CNC programming under one roof

Over the past decade, the biggest change in the automotive industry has been the shortening of development time for new vehicles. And the biggest change in RapidFit? “Our share of the total value chain in the automotive tools we produce. And that’s exactly in order to help us meet those challenging lead times,” replies Filip.

“The value chain for automotive tools can be incredibly complex. Production alone can involve multiple technologies, including 3D printing. With CNC milling, the most vital value addition is the programming stage, and it’s a major step-up for our customers to have that programming handled in the same place that managed the design. In the vision of Industry 4.0, your data flow has to master your production flow. By bringing more elements in-house, from CAD design to CNC programming, we’re making our backbone of services complete.”

For customers of RapidFit — a formidable list including most of the top ten automotive parts suppliers as well as major car brands — more in-house processes at RapidFit ultimately means that RapidFit has more control over quality and lead-time.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.