CUSTOMER STORY

How a Resorbable Bio-Ink Start-Up Creates Patient-Matched Bone Implants with 3D Printing

Ossiform, a company dedicated to redefining replacements for people with bone defects, looked to 3D printing to create an ideal set of processes that would allow them to provide more natural bone implants. They needed a complete software solution that could facilitate the total patient-specific implant creation process of their orthopaedic bone implants. With the help of Materialise solutions, they were able to streamline their workflows and focus on what really mattered to them — bringing their innovative ideas, which can improve the lives of patients, into reality.

From fully resorbable bio-ink implants to real, living bone

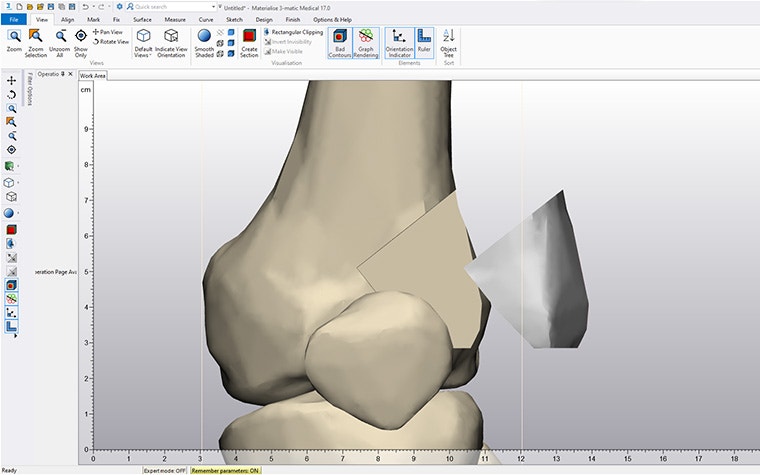

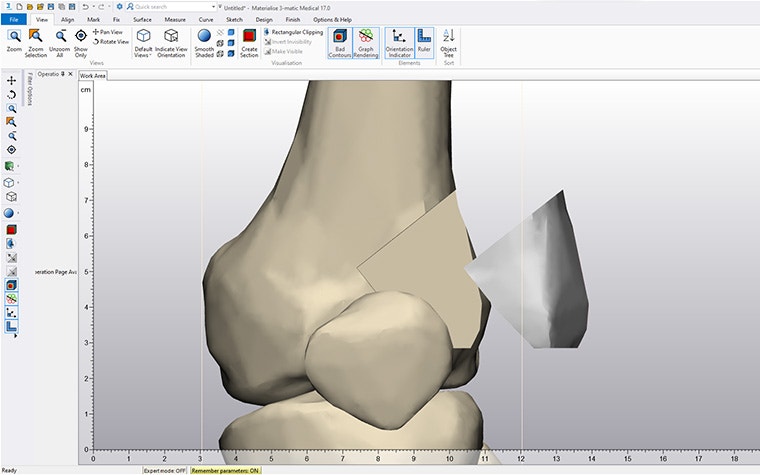

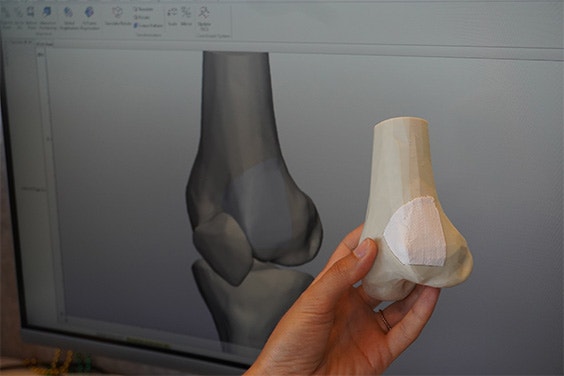

Ossiform has developed a technology that allows them to create implants made from a fully resorbable bio-ink that allows the implant to remodel over time and become real living bone. The process begins with patient scan data, which is segmented into the site in need of repair. A base model of the damaged site is created and subsequently virtually reconstructed using computer-aided design (CAD) tools. Ossiform can then use the designed reconstruction to manufacture a bone implant of exact anatomical fit and with a clinically relevant porosity that facilitates the ingrowth of the patient’s native bone tissue. Ideally, this entire total process is handled in a case management software that allows for rapid collaboration through feedback between Ossiform and the surgeon performing the surgery.

Finding the right software partner

As Martin Bonde Jensen, CTO and Co-Founder of Ossiform, explains, “Many of such total software solutions can be constructed by handpicking and combining several tools from different vendors. At Ossiform, we explored such possibilities initially, but since Materialise could provide everything we needed in one solution, it was an obvious choice for us to partner up with Materialise to provide the complete solution.” Today, they utilize Materialise Mimics and 3-matic to create patient-specific designs initially for the internal validation of their production processes — with the aim to produce patient-specific implants for various groups of orthopaedic patients. He adds, “The fact that Materialise has also gone to great lengths to get their software solution approved at respective regions’ regulatory authorities only made the choice easier.”

3D-printed model of the defect and its fitted bio-resorbable implant

Scaling up and continuing to provide high-quality implants

“With the help of Materialise, Ossiform will be able to provide patient-matched bone implants at the highest quality standard to the millions of patients in need of bone reconstruction globally each year,” says Martin confidently. And in the not-so-distant future, Ossiform believes that point-of-care (PoC) 3D printing will be the preferred method for hospitals and surgeons to acquire many of their implants. They hope their technology can be implemented at the point of care for rapid implant production, ultimately minimizing the time to surgery. Ossiform intends to help hospitals set up their PoC facility with the needed hardware, standard operating procedures for their operation, and quality management guides to implement in the hospital’s systems — as well as provide their trialed and tested bio-ink.

Martin adds, “Obviously, the material is only one part of the full implant solution, with the second part being the design, which we believe Materialise can help with their extensive experience. It is also just one of the countless exciting reasons why we at Ossiform are thrilled to venture into the future of bone reconstruction with Materialise.”

L-103451-01

Disclaimer: The implant illustrations shown are intended to demonstrate potential use cases of Ossiform’s technology based on preclinical validation trials. Products have not cleared by the regulatory authorities at the time of publication of this article.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.