EXPERT INSIGHT

Singapore’s Got Talent: NYP Teaches Students and Companies How to Leverage Additive Manufacturing to Grow Their Skills with Our Software

Nanyang Polytechnic (NYP) is an Institute of Higher Learning (IHL) that equips Singapore’s brightest minds with the knowledge and expertise to make a real-world impact. And one in-demand skill around the world is additive manufacturing (AM). To keep the country at the forefront of innovation, Singapore’s government is helping local businesses tap into AM’s various benefits to transform dozens of industries, from manufacturing and aerospace to medtech — with help from prominent educational institutions, such as NYP.

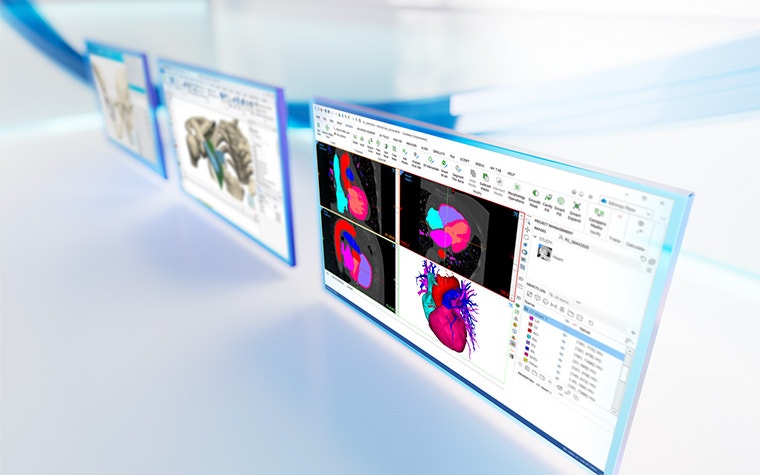

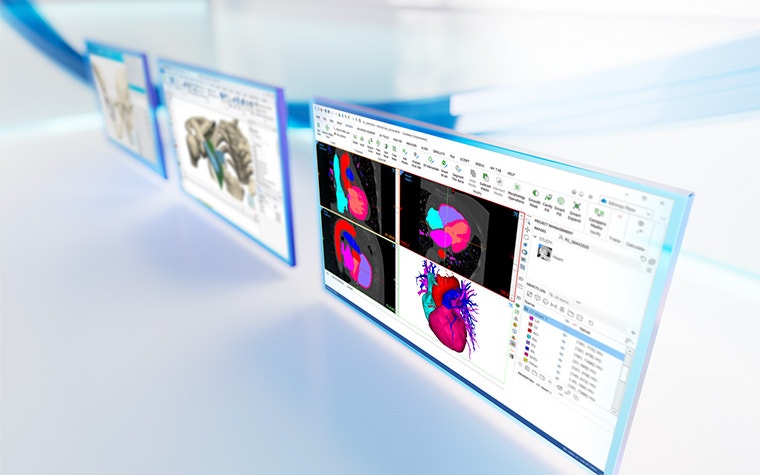

They’re facilitating this knowledge transfer by collaborating with us (one of their industry partners), and using our powerful AM software: Materialise Magics and Mimics.

Our survey showed that finding skilled employees is a challenge for companies and holds them back from adopting AM. However, the growth of the global 3D printing market is booming, from less than 20 billion in 2022 to a projected 100+ billion by 2030.1 NYP addresses this issue, being one of the early adopters of AM, and continues to be a leading IHL in this field.

“We provide a holistic range of diplomas and programs for our students,” says Zaw Hlwan Moe, Master Specialist (Additive Manufacturing) at the Additive Manufacturing Innovation Centre (AMIC), School of Engineering, Nanyang Polytechnic. “AMIC specializes in AM. Our engineering school is renowned for embracing innovative technologies like 3D printing, offering in-depth training sessions and courses to students, as well as partnering with businesses to help them develop their capabilities,” he says.

Materialise has a strong relationship with NYP, signing a memorandum of understanding (MoU) with them ten years ago. The agreement was a commitment to offer our support, insights, and practical knowledge regarding 3D printing and equip their AMIC with our advanced 3D software. “I used Materialise Magics since 1999, and we expanded to include Mimics after we [an NYP team] visited Materialise’s HQ in the 2000s,” says Zaw Hlwan Moe. “We’ve collaborated with Materialise for years, and many senior members from Materialise visit our campus regularly. We value our partnership and Materialise’s software solutions, of course.”

Does not compute! Cutting out errors and orientation mishaps

“Apart from being really user-friendly, one of the most important benefits of using Magics is its error corrections,” states Zaw Hlwan Moe. “In the past, we used other software to support our AM design and 3D printing industry projects. We have since switched to using Magics and Mimics.”

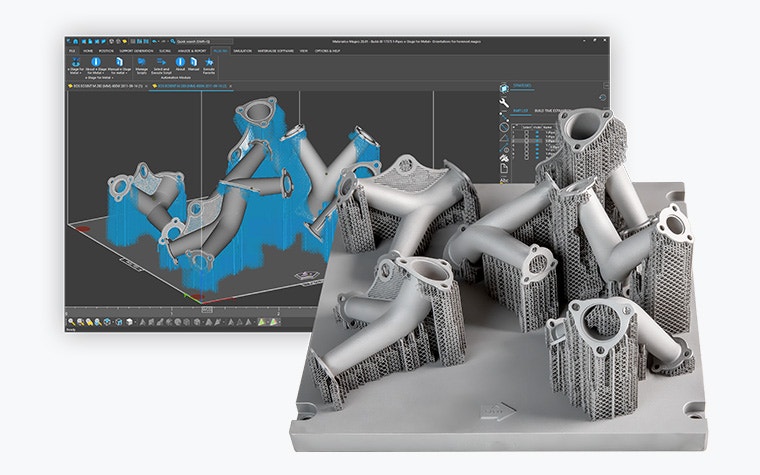

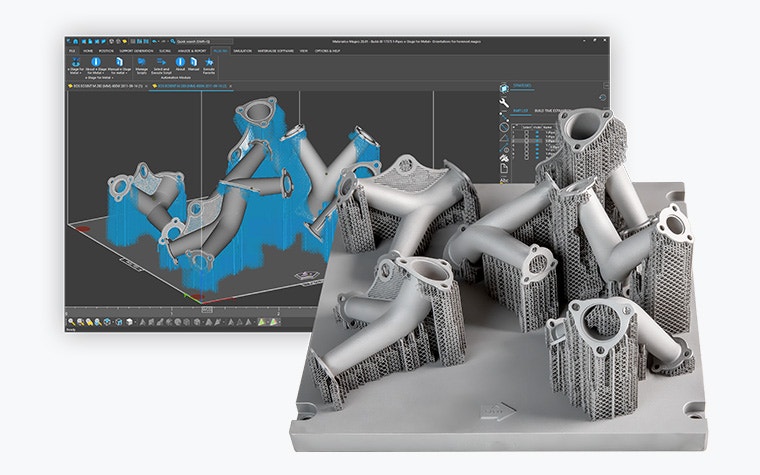

The two tools serve different purposes but help users more efficiently process AM designs and workflows. “Magics helps us correct AM data translation or STL errors, while Mimics eliminates human errors when defining the left/right orientation for DIACOM data. A user can easily print a component that’s the wrong way around if they’re not careful,” he explains.

NYP has a team working on AM projects using the software, with a mixture of educational, academic, and business licenses. So, dedicated AM software that helps streamline various processes saves them time and resources — while taking away stress.

“STL errors are problematic; they usually happen because data translation is incompatible with either software or 3D printers. Many product designers use third-party software to create aesthetically pleasing surface models. When they export to STL, there are many errors. Without Magics optimizing the file, we’d waste time and resources.”

“Mimics is also important when looking at DIACOM import and patient data, as Mimics helps manage and analyze metrics before fixing them. Additionally, the software cleans up the noise in DIACOM files and helps with segmentation, which would need to be done manually. The process is very labor-intensive without Mimics,” says Zaw Hlwan Moe.

In fact, the NYP team is so pleased with our solutions that they’re considering whether to incorporate the Magics’ Ansys Simulation module into their course syllabus in the near future. “Based on our experience of the SG+ module used for metal part optimization, we think there is potential to use the Simulation module in our courses. Lip Gang Chong [Solution Consultant at Materialise Malaysia] came down to Singapore for a demo. The demo was insightful; the module looked efficient, easy to use, and was up to the same standard of other pre-print software products,” he says.

More support, less stress — AM software and experts give NYP a helping hand

NYP consistently upgrades to the latest version of Magics and has since renewed the MoU to ensure they have the most advanced AM tools to teach their students.

“NYP contacts us when they want to upgrade any modules or use new software,” says Lip Gang Chong. “We also provide demos, help with technical support, and provide our expertise whenever they need it. We’ll support them when they upgrade to Magics 29 later this year after the launch in May [2025],” he continues.

In the meantime, Zaw Hlwan Moe is impressed with the Support Generation metal module (SG+). It’s an extensive toolbox that combines customizable non-solid and solid structures to help optimize support and heat transfer to avoid detachment or warpage. The result? SG+ minimizes build failures and ensures excellent part quality.

“I love the tool’s dynamic orientation. In the past, we’d have to orientate the part, check the support generation, orientate the part again, etcetera, until we got it right. It was a difficult and repetitive process, and we hoped there was a better way. With the introduction of dynamic orientation, we can see whether the support generated is sufficient or not.

“We explored introducing this into our course so students could learn advanced features and increase their metal AM knowledge. The SG+ module is perfect for unlocking sophisticated metal AM designs and support optimization. We’ve also seen many of our past graduates return to NYP for continuing education and training (CET) courses that leverage the SG+ module to deepen their skills in handling complex metal components,” states Zaw Hlwan Moe.

Along with providing short courses on 3D printing, NYP also collaborates with Materialise to provide in-depth training sessions. “Before COVID-19, we used to invite local industry partners and businesses to in-person events so they could learn the latest insights in the 3D printing industry,” says Zaw Hlwan Moe. “Now, we have a mixture of online and in-person courses. We want to proliferate our AM knowledge and grow the industry in Singapore and the wider ASEAN region.”

A big red dot: How AM collaboration and NYP are helping Singapore stand out

Singapore has a 40% share of the AM market in the Association of Southeast Asian Nations (ASEAN)2, a political and economic union of ten Southeast Asian states representing more than 700 million people.3 Furthermore, an increasing number of firms want to use AM’s flexibility, design freedom, and opportunities for personalization within their production workflows. NYP is one of only a handful of institutions capable of training them to use AM effectively.

“AM software is useful for our industry partners, but they need to know how to use it effectively,” says Desmond Tan, Centre Director (Additive Manufacturing Innovation Centre) at the School of Engineering, Nanyang Polytechnic. “NYP helps them leverage the benefits of AM to grow their businesses. Materialise is one of the key parts of our strategy to grow AM’s use in ASEAN and further afield via our training courses and industry partnerships.”

The SEA region is an important area for Materialise and the manufacturing industry. The more companies with skilled AM workers, the greater AM’s adoption rate and the increase of innovative applications that will make a difference worldwide.

“3D printing has developed into a valuable complementary production technology. We look forward to continuing our partnership with NYP and their goal of helping companies progress in their 3D printing journey,” says Kelvin Wee, Sales Director at Materialise Malaysia.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.