EXPERT INSIGHT

3D Visualization and Guidance: Transforming Musculoskeletal Trauma Surgery from an Art to a Predictable Craft

3D visualization and guidance technology are changing the game in trauma and orthopaedics, revitalizing traditional workflow patterns and providing creative new ways to meet patient needs. With infinite potential for growth and evolution, the prospects are very exciting.

We've teamed up with various leading specialists in the field of orthopaedic surgery to create the THINK Medical 3D Printing webinars, demonstrating the various applications for 3D visualization tools and 3D-printed models through actual clinical case studies.

A need for more precise musculoskeletal imaging

Prof. Stefaan Nijs, Chairman of Trauma Surgery at Leuven University Hospital, explains in his webinar, ‘3D and Musculoskeletal Trauma,’ how traditionally, one of the trickiest skills to master in musculoskeletal trauma surgery is understanding the 3D relation of elements based upon 2D imaging (e.g., X-ray imaging).

Although more advanced imaging technologies like CT scans have offered improved visualization, there was room for further development. Enter the Materialise Mimics software — an impressive technology that efficiently converts scans into accurate virtual 3D models.

As explained by Professor Nijs during one of his cases, traditional imaging of a calcaneal fracture can be challenging to interpret due to limited visualization. In this case study, the software allowed the surgeon not only to cut away bone and muscle that normally impede perception, but also to rotate the view around the fracture. Essentially, this software allows surgeons to isolate the fractured bone and look at it from all angles, enabling them to really tailor the type of intervention to be performed.

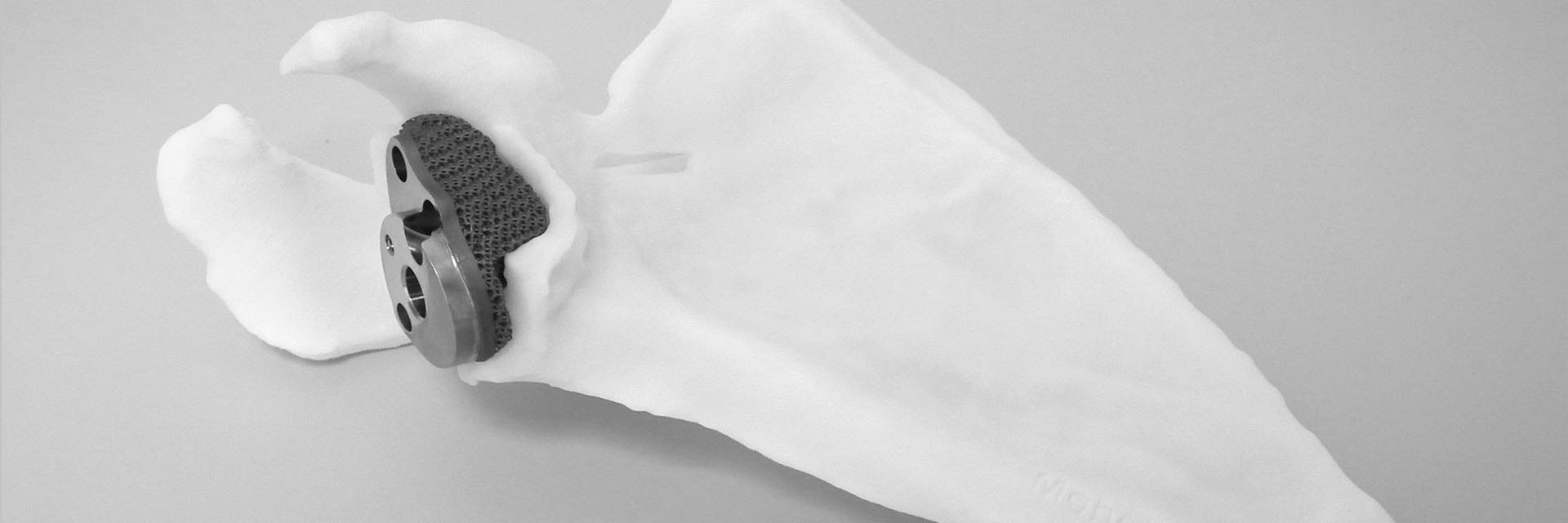

An even more precise image is possible by printing out virtual 3D images, not only of the fractured calcaneus, but also of the mirror-opposite healthy bone. Having a good view of the opposite bone makes understanding the fracture patterns much more straightforward. This type of resource also enables surgeons to plan ahead in terms of shaping implants and achieving an improved fit (using the mirror opposite bone as a baseline). In this particular case study, the implant was ready and available prior to surgery.

For a 17-year-old patient who had sustained injuries after a fall from horseback, Prof. Nijs examined her proximal humerus in 3D and noticed that it was significantly malaligned, which caused pain and loss of motion. After analyzing the CT scans in 3D, he realized that the head of the shaft needed to be realigned, meaning the patient would have to undergo an osteotomy.

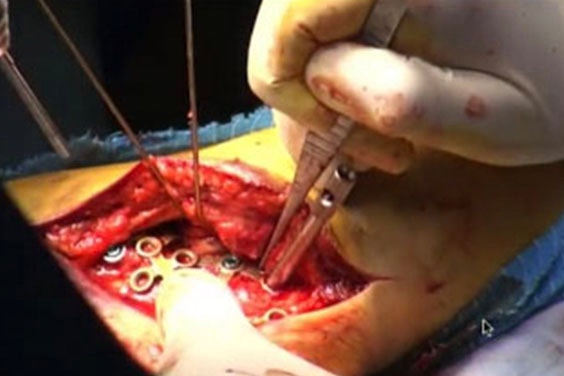

Using Materialise SurgiCase to manage communication between Prof. Nijs and the team at Materialise, the surgery was planned and drill and cutting guides were designed and printed. He performed the surgery with a better overview of the patient’s condition, and after the operation, a control CT scan showed that the fracture had healed as planned, resulting in a happy patient!

The benefits

As Prof. Nijs says, patients don’t conform to an average; patients are specific. With 3D-printed medical implants, the implant can be adapted to the patient’s specific anatomy, and for Prof. Nijs, 3D-printed implants in post-traumatic surgeries have huge potential to solve dramatic cases that would not have a solution otherwise. The current workflow is still not fast enough to be able to treat these severe trauma cases on time, but Prof. Nijs is convinced that one day this will be a possibility.

At the end of the webinar, he highlights some of the benefits of incorporating 3D planning and printing technology into his surgical workflow as he experiences it in his daily practice.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.