EXPERT INSIGHT

Designing for AM in Automotive: Discover Hyundai Automotive’s Award-Winning Print

When considering automotive manufacturing, which factors first spring to mind? Innovation? Speed? Safety? All true — and all reasons why 3D printing adds significant value to the industry. From quality inspection to prototyping to end-use parts to optimizing production lines, you'll find additive manufacturing (AM) is used extensively to leverage these advantages.

The automotive industry is known for rapid innovation, so it’s no surprise that car manufacturers and their suppliers turn to 3D printing to optimize production. These businesses rely on technologies that provide reliability, speed, cost-effectiveness, and safety so they can remain at the forefront of the industry.

But in order to bring 3D printing’s capabilities to life, one must first understand how to design for the technology properly. With the right know-how and tools, automotive companies will set themselves apart from the competition thanks to the following advantages.

Faster time-to-market

In an innovative market such as this, competition is tight, and businesses place a focus on quickly getting concept cars on the road. Additive manufacturing for automotive enables engineers to quickly iterate component designs to have the final part in hand sooner. If a change is needed, they no longer need to experience the long waiting times for new prototypes that traditional technologies require. Instead, they can make edits digitally using design optimization software and have the new part ready to test in hours.

Incorporating 3D-printed parts into production lines also prevents downtime. If a replacement part is needed, companies have a virtual warehouse of designs where they can choose the replacement part and have it printed right away. No more production delays.

Lightweight parts

Freedom of design is a major benefit of 3D printing. Without the constraints of conventional manufacturing methods, engineers can create optimized designs that give a new meaning to automotive parts: strong yet lightweight. One clear benefit to this is more cost-effective parts. Lighter designs use up less material and cost less to transport.

Another advantage is that incorporating lightweight parts within production improves ease of use. With more ergonomic tools, a single operator could handle the job on their own, thus reducing safety risks. The RapidFit team, a Materialise automotive tooling company, finds this especially valuable for their jigs and production tools.

Design for additive manufacturing in action: Hyundai Automotive

As mentioned previously, if organizations want to use AM to its full potential, they must be sure to design parts with AM in mind. This skill was put to the test in Ulsan, South Korea, where they recently held their fourth Design for Additive Manufacturing (DfAM) competition.

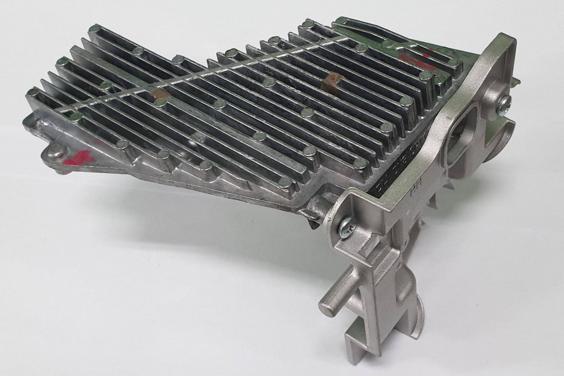

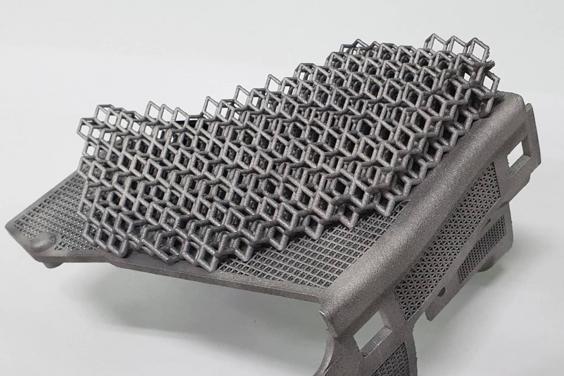

The winners? The ‘ThinkSink’ team from Hyundai Automotive and SL Corporation with their design for a headlight heat sink. With an optimized design for this part that replaces STL volume areas with lattice structures, the team found that they could improve thermal efficiency, manufacturing lead times, build success rates, and weight reduction.

Conventionally designed headlight heat sink vs. the Hyundai team’s 3D-printed heat sink.

“We were able to quickly work on complex structural designs,” explains team member Ik-sung from SL Corporation. “The procedure was simple and straightforward; we created a design space in CAD software, then worked on the lattice structure in Materialise software.”

With their final design, the team managed to reduce the weight of the heat sink by 45% when compared to the traditional design, bringing their team the win.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.