PATIENT STORY

ACCISS Addresses Complex Cases Head-On with Advanced Healthcare Technology

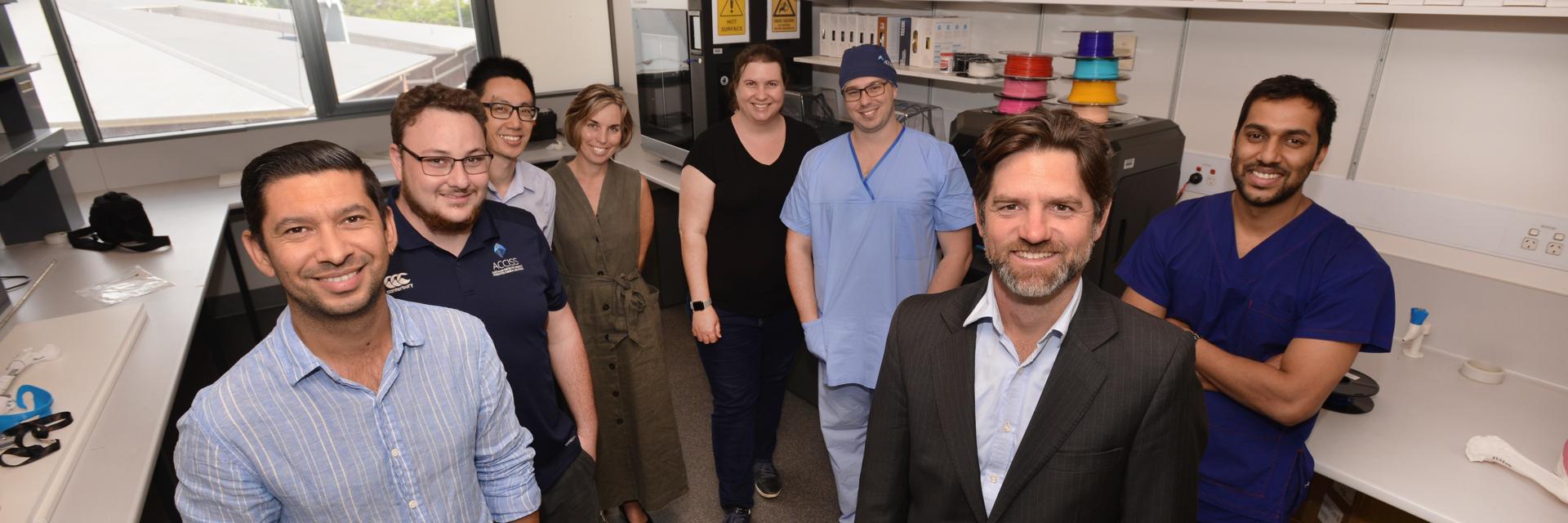

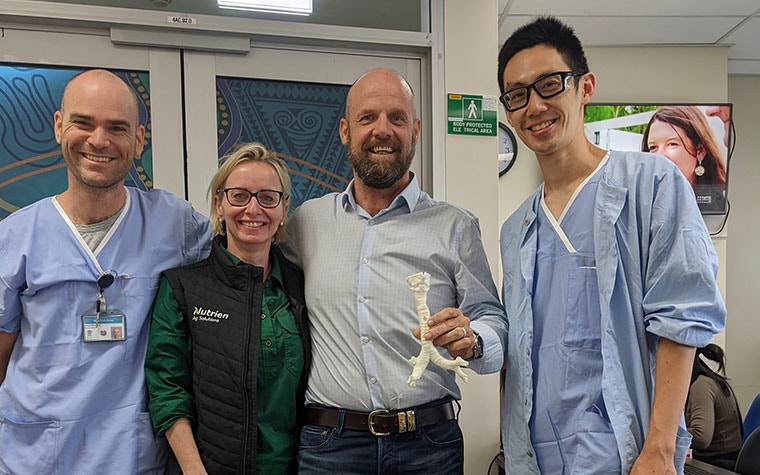

By founding ACCISS (Australian Centre for Complex Integrated Surgical Solutions), Dr. Michael Wagels set out to provide a service that offers hospitals support for the most complex patient cases. ACCISS' strong engineering, clinical, and regulatory expertise allows its team to make advanced technology like 3D printing, virtual surgical plans, and the design of assistive medical tools accessible to clinicians. Five years later, ACCISS has successfully integrated its services into Princess Alexandra Hospital and assists in more than 100 cases per month. And this is just the start.

The case that started it all

"Like all interesting clinical stories, it started with a patient and a problem..." ACCISS Founder Dr. Michael Wagels starts off the organization's origin story with his inspiration: a patient who had developed spontaneous osteomyelitis of his tibia. He was involved in this case where the patient, unfortunately, had 36 centimeters of his tibia resected due to a lack of alternatives. But it sparked a question for Dr. Wagels. How can he help to offer more options in cases such as this?

"So I began trying to work out not just how to access certain aspects of 3D modeling for my purposes, but also how to make 3D modeling — and ultimately 3D printing, prototyping, and implantable devices — available to a wide range of clinicians who would otherwise not really know where to start," explains Dr. Wagels.

From there began the journey of building infrastructure, securing funding, and onboarding the next generation of clever engineers. Now, as a mature team with reliable workflows, ACCISS supports clinicians at Princess Alexandra Hospital with a range of in-house services, from clinical trials to new medical device innovation.

Introducing point-of-care manufacturing to hospitals

"Adding the necessary tools and technology into hospitals better enables us to offer customized services," shares Dr. Allison Sutherland, Deputy Director at ACCISS. "Starting this process with Princess Alexandra Hospital was a natural decision since we're located on the same campus."

As a nascent surgical support service, they first had a couple of challenges to take on for successful integration. Naturally, step one was proving the value 3D printing and planning services at the point of care bring to a hospital with a well-established radiology department.

"We had to demonstrate that 3D modeling, visualization, and printing are adding in that extra degree of sophistication in understanding and improving what we can deliver to the patient and to the health service more broadly," says Dr. Sutherland. "So we summarized what we've done over the last two to three years with other hospitals, what our capacity is for the future, and ultimately, how we can improve the surgical outcomes for the various surgical disciplines that we support and provide expert guidance in terms of the computational modeling."

Once the integration was ready to go into action, the ACCISS team knew they'd have to find the best method for smooth multidisciplinary collaboration with the existing hospital teams. One step they took was establishing a directorate to set the strategic direction, consisting of clinicians representing a variety of disciplines where point-of-care manufacturing and medical devices play critical roles.

A point-of-care team at Princess Alexandra Hospital also demonstrated engineers in roles that aren't typically expected. Previously, clinicians were accustomed to working with applied engineers that service medical devices. On the other hand, ACCISS senior engineers are health professionals with hands-on roles. The team needed to clarify to hospital staff how ACCISS engineers are unique and their responsibilities in this 3D model and computational service.

"We have the engineers and relevant specialists around the table, meeting regularly to discuss how we're going to develop and expand the service within the hospital," explains Dr. Wagels. "It allows them to get a better understanding as it evolves — how the service needs to run, the role of the engineer — and they can then disseminate that information amongst their specialty colleagues."

And ACCISS also added the role of junior doctors, such as Dr. Brandon Leggett, to deliver its services. "I'm able to bridge the gap by explaining the clinical problems to the engineers," shares Dr. Leggett. "We can seamlessly introduce the system ACCISS has created into the hospital environment."

Making a difference in a life-changing case

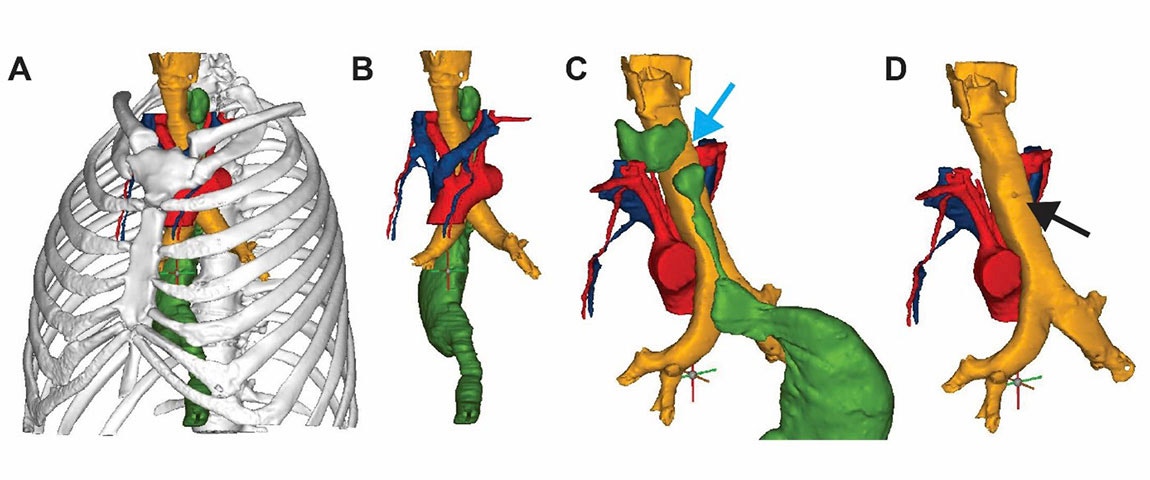

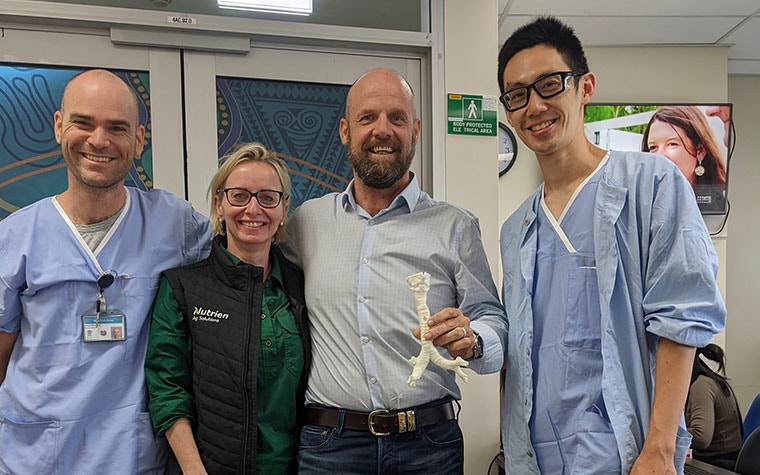

A shining example of the work that the teams achieved with 3D planning is a case involving complications experienced by a patient after an esophagectomy. Six days after the procedure, the patient faced life-threatening complications caused by a leak. After an emergency intervention to drain gut contents from the airways, the team had to determine which surgical approach would be the most promising solution for this patient.

"This was an ideal case for support from ACCISS because it was an extremely complex complication after what was already a major surgery," explains Upper Gastrointestinal Surgeon Dr. Adam Frankel. "It required multidisciplinary input and presented a real challenge in terms of preoperative planning and visualization.

"The major role that 3D planning played was demonstrating the relevant anatomy and the possible surgical approaches because there were a number of ways we could approach this problem. Based on CT modeling, none of them appeared to be particularly good. But the 3D visualization helped us settle on which of the three possibilities was the preferred option. And as an engineer himself, it was exciting for the patient to experience doctors interacting with his profession to identify the best outcome for him."

“We went through plan A, plan B, plan C, and that made a huge difference in stress levels on the day of the surgery and avoiding a potentially life-threatening situation.”

— Dr. Adam Frankel, Upper Gastrointestinal Surgeon, Princess Alexandra Hospital

Complete 3D model of the patient's anatomy with mediastinal components.

The ACCISS team visualized the case using Materialise Mimics for segmentation, Materialise 3-matic for surgical planning and 3D printing preparation, and Materialise Viewer to share the digital models with the clinicians.

"Mimics' versatility in identifying a lot of the soft tissue components of that patient's anatomy was absolutely critical," says Dr. Leggett. "There aren't a lot of inbuilt CT software packages that support soft tissue anatomy. The ability to segment out an esophagus, or residual stomach in this case, and then match that with the patient's airway and vascular anatomy was a key component in the ultimate decision regarding the surgical approach."

With the 3D visualizations in hand, collaboration between the clinicians and communication with the patient became much smoother.

"Thanks to the 3D models, I could sit down with all the experts involved in the procedure and go through every possible scenario with them. We went through plan A, plan B, plan C, and that made a huge difference in stress levels on the day of the surgery and avoiding a potentially life-threatening situation," explains Dr. Frankel.

"It's such a breath of fresh air from a patient's perspective to show them a colored, segmented model that turns something that would otherwise be extremely foreign to them into something that's easily understandable. In this case, the 3D visualization was extremely helpful in what was otherwise a very stressful situation for that man and his family. The reduction in anxiety in the room was palpable. You can just see the understanding wash across their faces."

The next stops on ACCISS' roadmap

Since its formation, ACCISS has increased its output from five to ten cases per month to 100 – 120 cases per month. And their expansion plan — bringing point-of-care services to even more healthcare centers, adding on-site clean rooms, and getting involved in more beta testing with Materialise — will help them boost these numbers even further.

In terms of the technology they think will play the biggest role in the future of healthcare, their focus is on augmented and virtual reality (AR, VR). 3D-printed models are a valuable step toward planning outside of a 2D environment, but the potential of AR and VR to eliminate printing time, avoid sterilization steps for use in the operating room, and minimize waste makes the technologies attractive options for the future.

The work that ACCISS is doing to make reliable treatment more accessible for the most complex cases is truly remarkable. We look forward to seeing what they accomplish next!

Image credit: ACCISS and Princess Alexandra Hospital

L-103153-01

Materialise medical device software may not be available in all markets because product availability is subject to the regulatory and/ or medical practices in individual markets. Please contact your Materialise representative if you have questions about the availability of Materialise medical device software in your area.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.